Attachments

Working with Attachments

88 9821/6100-4 88

Notice: Some attachments may contact parts of the machine when in the fully folded position. Take extra care

to avoid damage to the machine.

Connecting/Disconnecting Hydraulic Hoses

WARNING Fine jets of fluid at high pressure can penetrate the skin. Keep face and hands well clear of fluid

under pressure and wear personal protective equipment. Hold a piece of cardboard close to suspected leaks

and then examine the cardboard for signs of fluid. If fluid penetrates your skin, get medical help immediately.

WARNING Hydraulic fluid at system pressure can injure you. Before connecting or removing any hydraulic

hose, residual hydraulic pressure trapped in the service hose line must be vented. Make sure the hose

service line has been vented before connecting or removing hoses. Make sure the engine cannot be started

while the hoses are open.

Some attachments are hydraulically powered. The following procedures show how to connect and disconnect

the hydraulic hoses safely.

Connecting the Hydraulic Hoses

1. Make the machine safe.

Refer to: Maintenance Positions (Page 122).

2. Vent the hydraulic system.

Refer to: Discharge (Page 147).

3. Check the hoses and adaptors for damage.

Refer to: Check (Condition) (Page 147).

4. Connect the hoses:

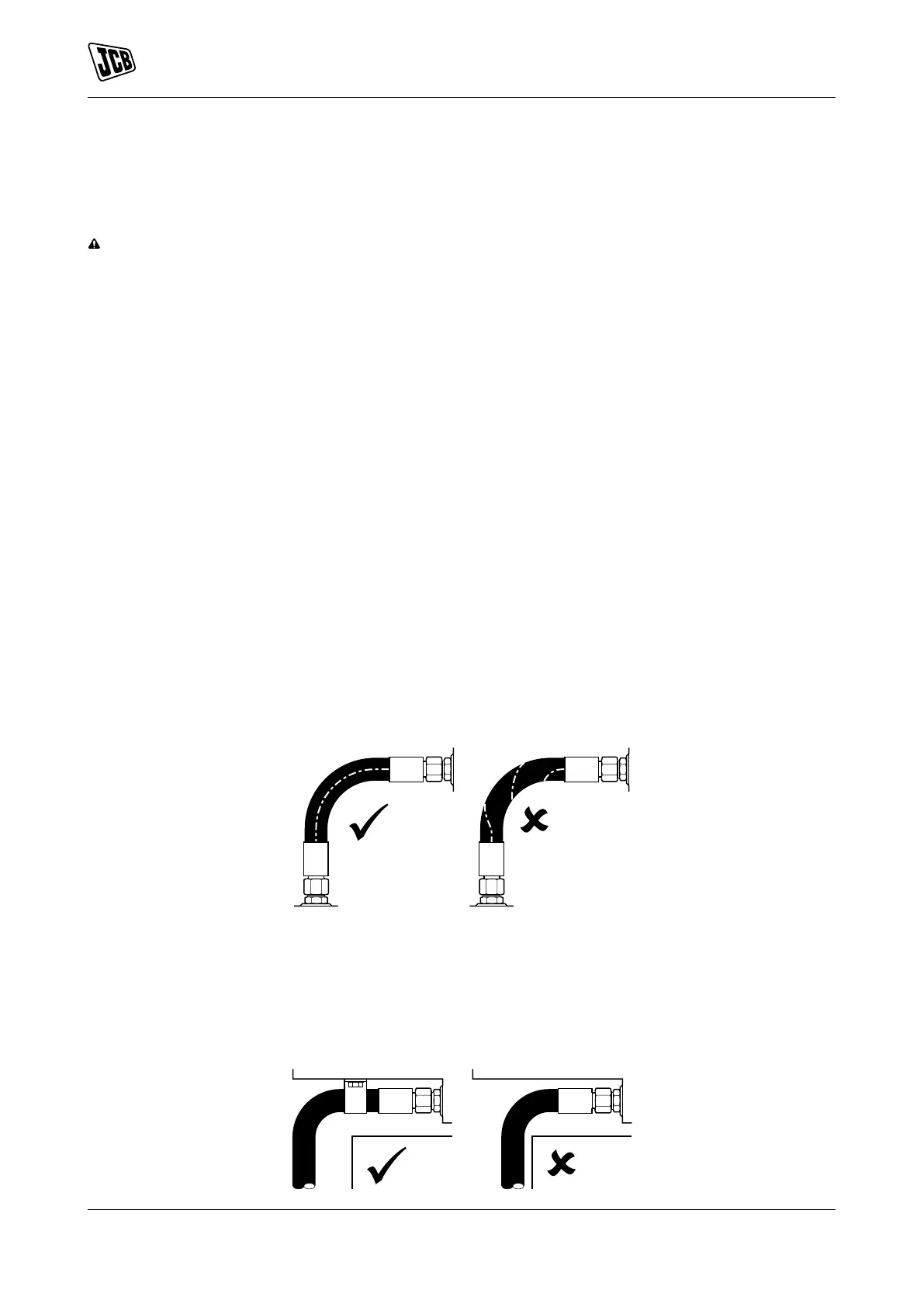

4.1. Make sure that the hose is not twisted. Pressure applied to a twisted hose can cause the hose to fail

or the connections to loosen.

Figure 73.

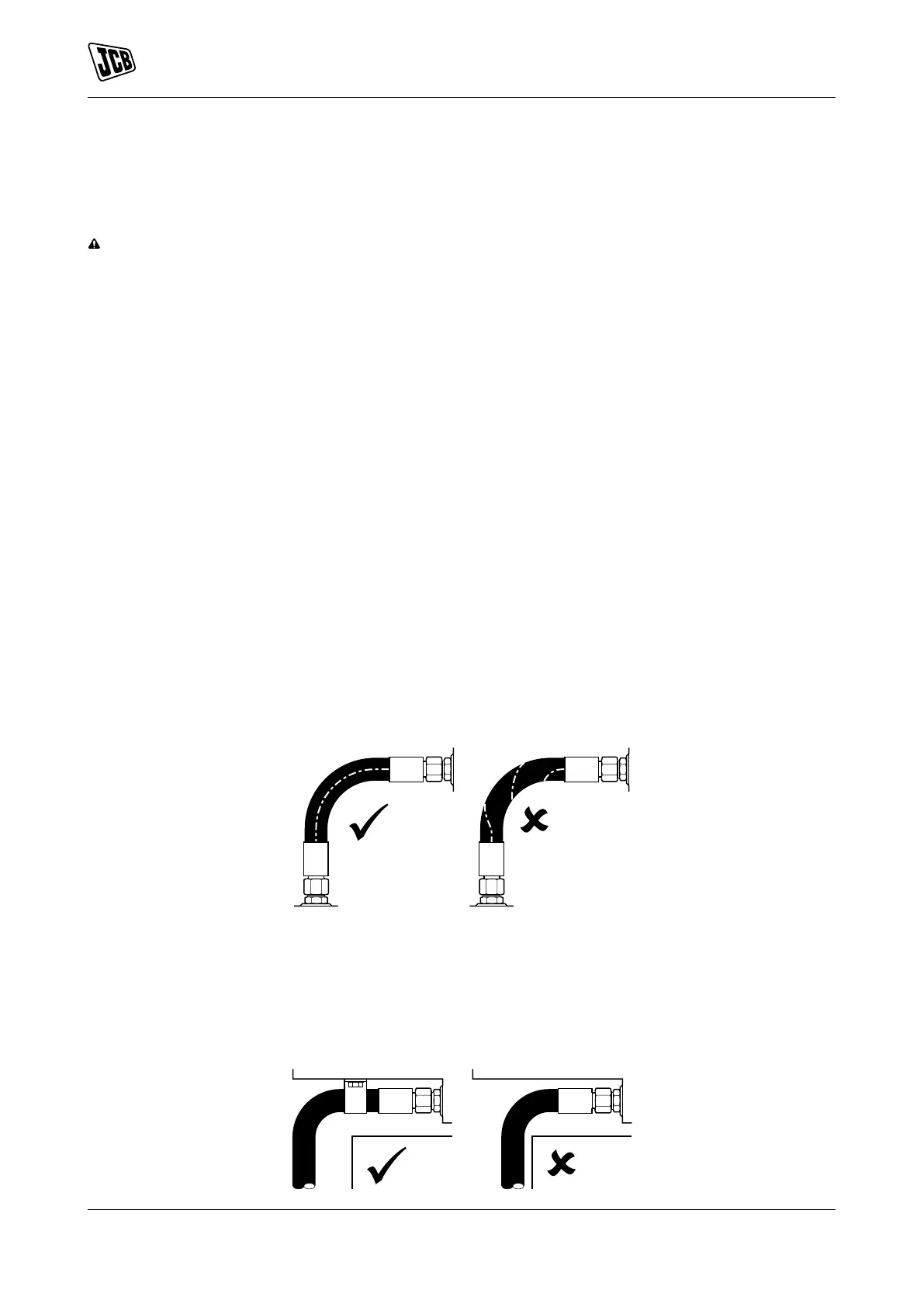

4.2. Make sure that the hose does not touch hot parts. High ambient temperatures can cause the hose

to fail.

4.3. Make sure that the hose does not touch parts which can rub or cause abrasion.

4.4. Use the hose clamps (where possible) to support long hose runs and keep the hoses away from

moving parts, etc.

Figure 74.

Loading...

Loading...