12 - 1

Fault finding

As a first step towards locating a fault, carry out the

following checks.

1 Check the hydraulic filter for the presence of excessive

foreign materials. The nature of the foreign materials

could yield a clue as to the source of damage or wear.

2 Check the flow rate and condition of the oil drained

from the pump.

3 Check for abnormal sounds and vibration.

4 Check the pressure at each of the pump pressure test

points.

Section E Hydraulics

9803/6410

Section E

12 - 1

Issue 1

Hydraulic Pump/Regulator

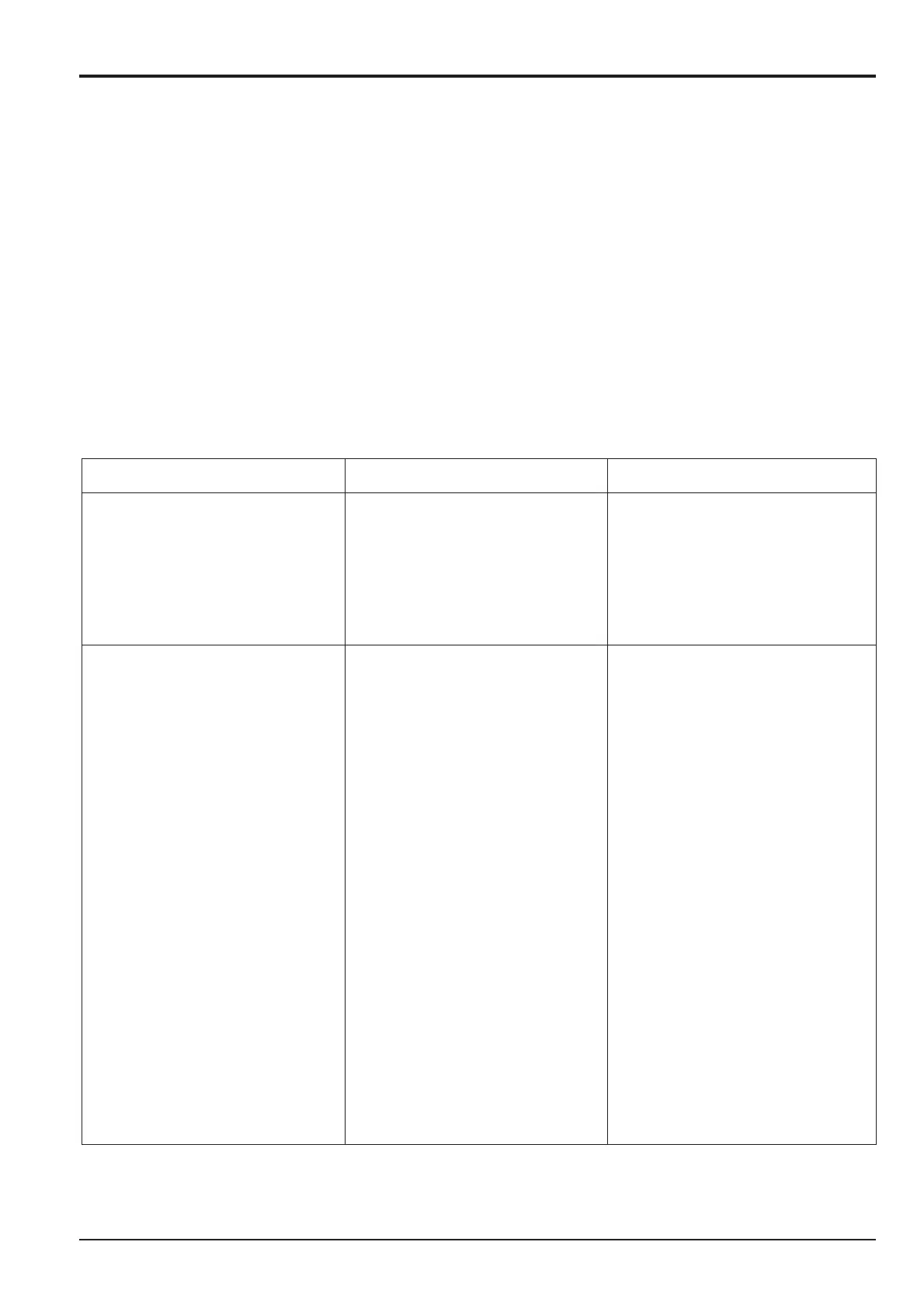

Symptom

1 No oil is delivered from the

pump.

2 Low pump flow rate, or circuit

pressure does not build-up.

Possible cause

a Suction strainer or suction line is

blocked.

b The suction strainer is above the

oil level of the tank.

c The pump itself is faulty.

a Incorrect operation of various

control valves or hydraulic

motors served by the pump,

causing low flow rate or loss of

pressure.

b The sliding area of the pump is

worn, allowing a large amount of

pressurised oil to escape from

the drain port.

c Air is being drawn into the

pump.

d The suction strainer is blocked or

above the oil level of the tank.

e Excessive suction resistance.

Remedy

Clean the suction strainer or clear the

suction line.

Top up the hydraulic oil tank and

bleed air from the system.

Dismantle and renew worn or

damaged parts.

Renew or inspect and repair the

defective control valve or hydraulic

motor.

Dismantle the pump and, if possible,

polish or repair by lapping.

If repair is not possible fit new parts.

i Check the hydraulic connections

for looseness and tighten if

necessary.

ii Check the hydraulic lines and

seals for damage.

Clean the suction strainer or, if

necessary, renew. Top up the

hydraulic oil tank and bleed air from

the system.

Check for abnormal oil temperature or

viscosity, or other factors causing

cavitation. Take the necessary

remedial steps.