2 - 1

Section 3 Routine Maintenance

9803/6410

Section 3

2 - 1

Issue 1

Service Schedules

Service Intervals for Hydraulic Oil and Filters when using a Breaker or Crusher

When using a breaker or crusher, contamination and degradation of the hydraulic oil occurs much more quickly than in normal

excavating use. If the machine is used with increasingly degrading oil it can cause problems in the control valve, premature

wear of the hydraulic pump and damage to the hydraulic system as a whole.

Servicing of the hydraulic oil and filters must be done more frequently according to the percentage of total operating hours

involving use of the breaker or crusher. When a breaker or crusher is fitted, ensure that the oil and filters are changed at the

intervals shown in the table below.

The hydraulic oil must be sampled and checked for contamination and degradation at the intervals shown.

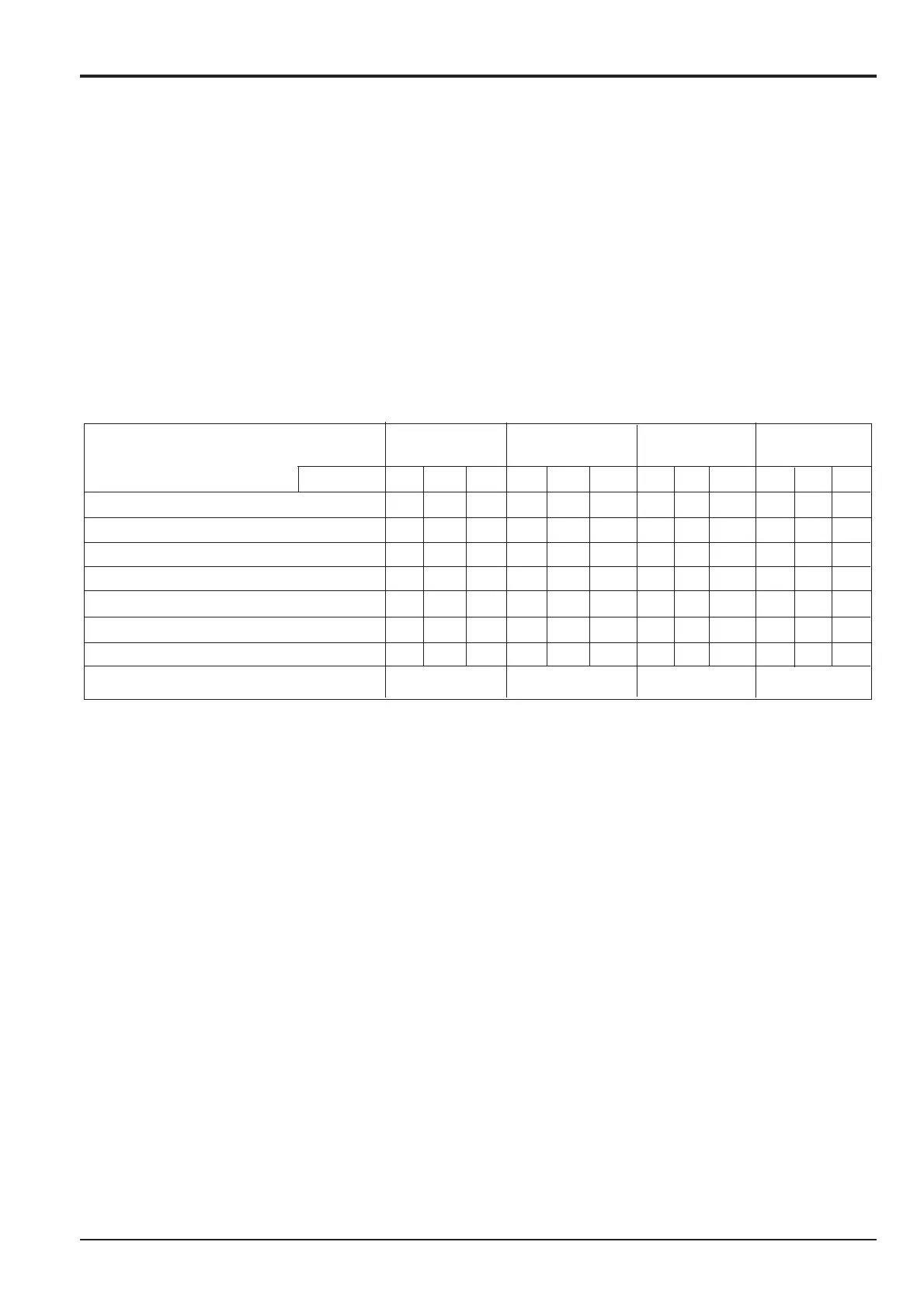

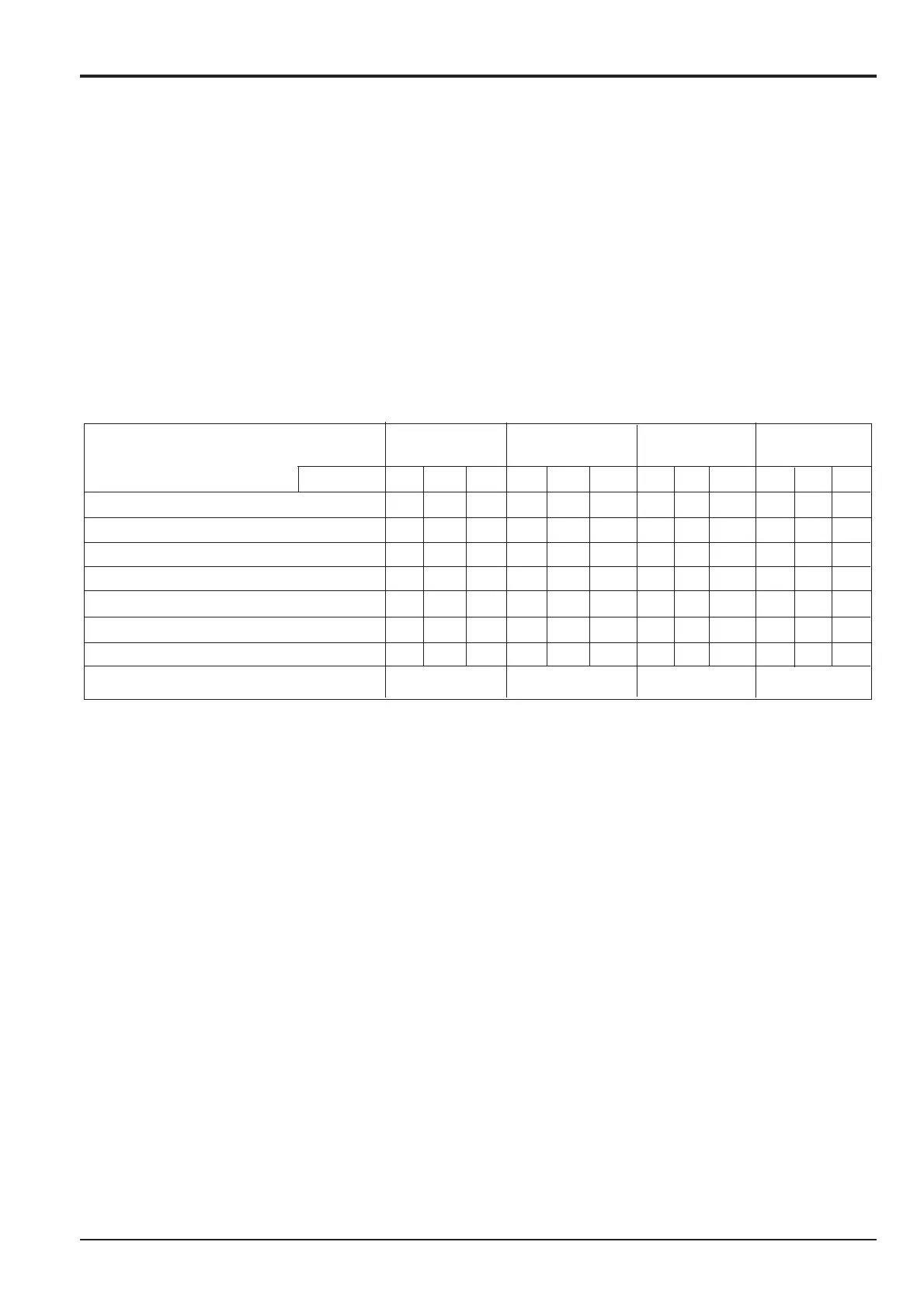

Use Frequency Use Frequency Use Frequency Use Frequency

100% 40% 20% 10%

Item Time (hrs) 10 100 600 10 300 1500 10 600 3000 10 800 4000

Hydraulic Oil ●● ● ●● ● ●● ● ●● ●

Return Filter ●●●●

Suction Filter ¹ ● ¹ ● ¹ ● ¹ ●

Drain Filter ●●●●

Servo Filter ●●●●

Nephron Filter ●●●●

Breaker In-Line Filter ●●●●

Hydraulic Oil Sampling

Every 200 hrs Every 300 hrs Every 600 hrs Every 800 hrs

●● Check oil level and top up as required ● Change ¹ Clean

Note: The filters must be changed whenever the period of breaker/crusher use exceeds 100hrs, regardless of the total

number of hours the machine has worked.

Loading...

Loading...