75 - 1

Disassembly JS200/JS240

Details of Service Tools used in the dismantling and

Assembly procedures are given in Service Tools, Section 1 .

Before starting work, clean all surfaces with a suitable

solvent and dry with compressed air.

Each part is precision made, so handle with care and do not

force any part as this may cause damage.

Protect the dismantled parts if they are to be left for a period

of time.

1 Drain the oil

2 Disconnect the external piping.

3 Secure the ram.

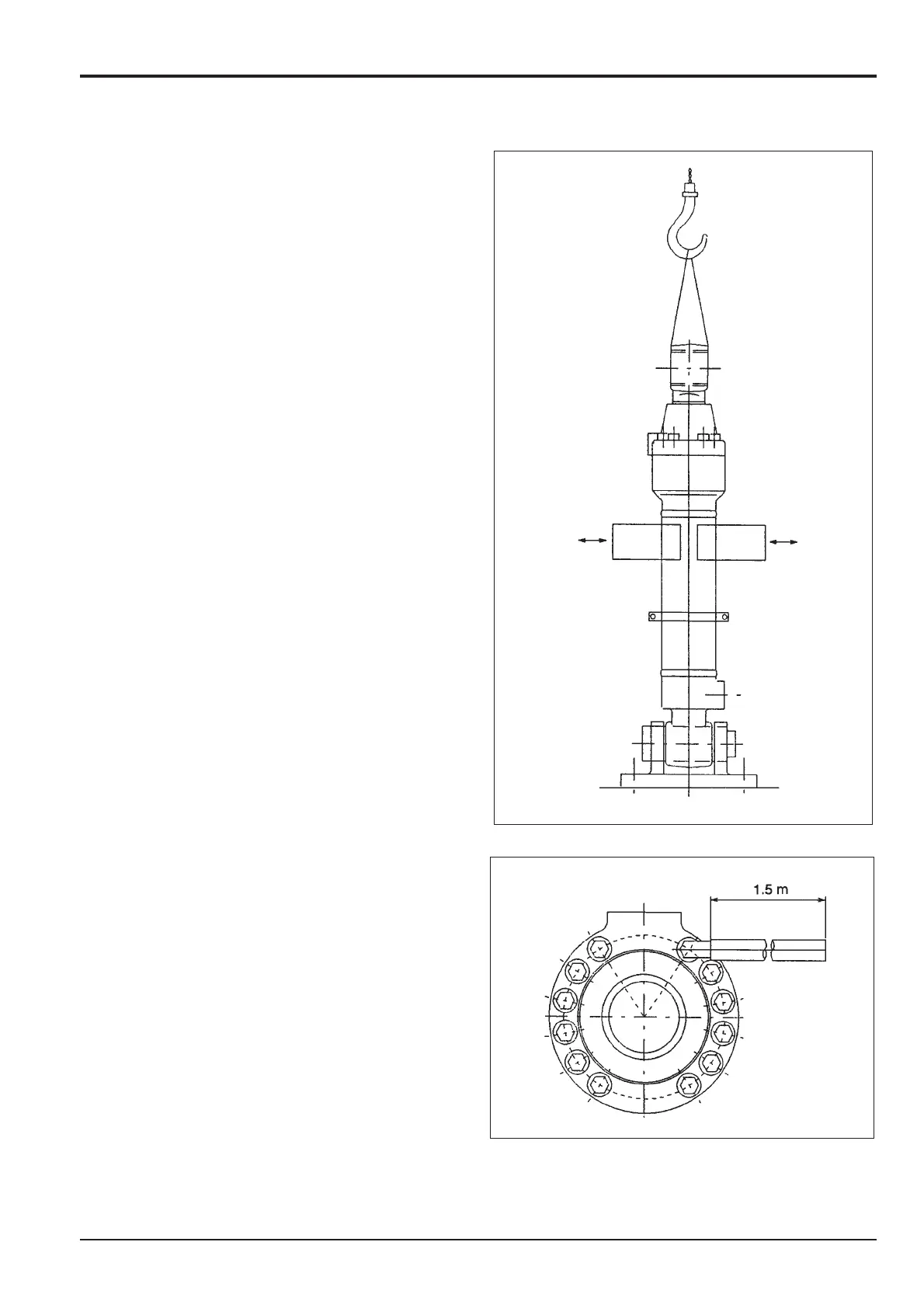

Note: Fix the ram in a vertical or horizontal position. The

vertical position is more favourable for

disassembly/reassembly work. Use the bottom pin hole for

preventing the ram from turning on its axis and for fixing the

ram in the axial position.

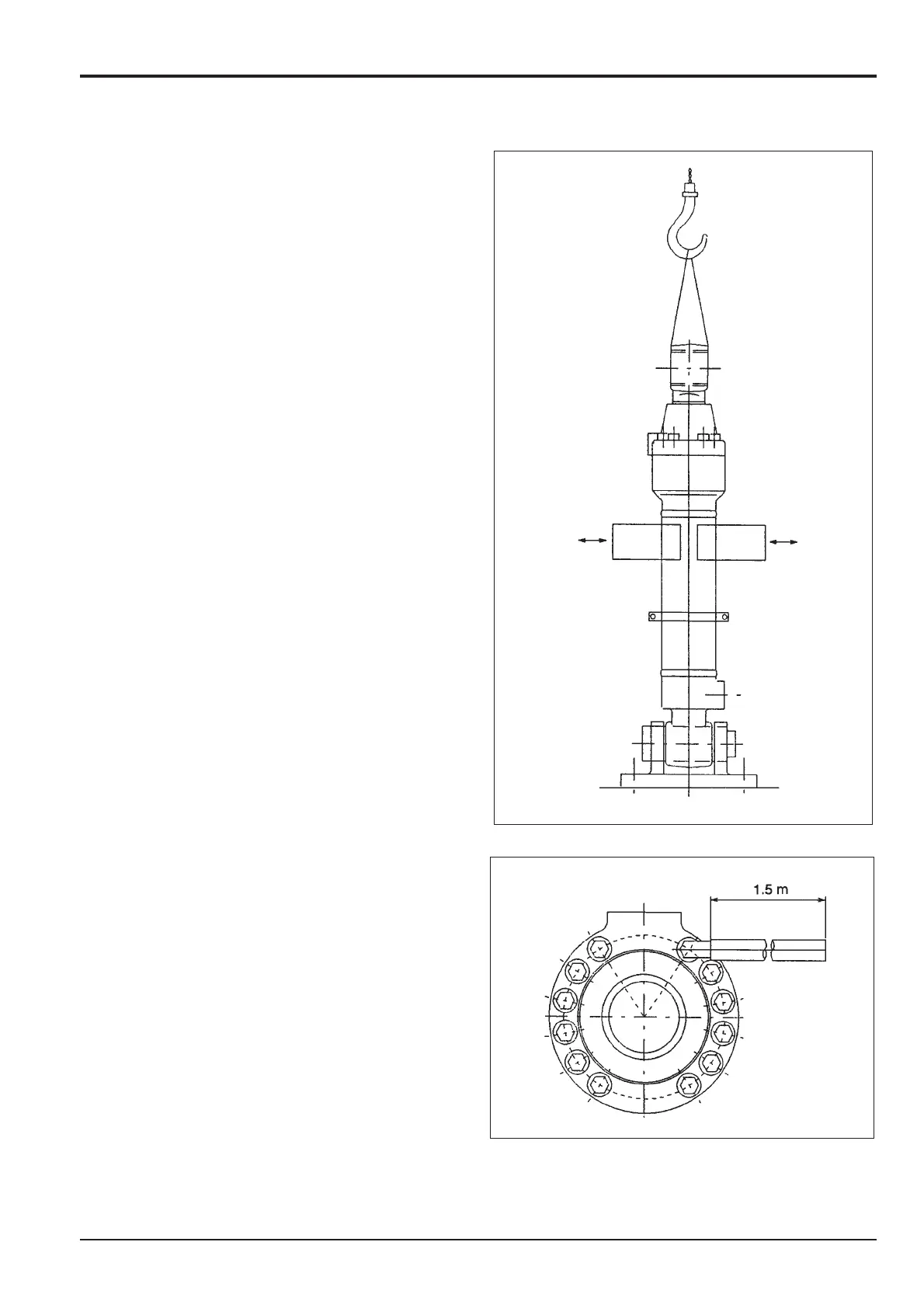

Remove the cylinder head cap screws (12 off) with an Allen

wrench. Use an extension pipe such as shown in the figure

below to facilitate bolt loosening.

Section E

Hydraulics

9803/6400

Section E

75 - 1

Issue 2*

Hydraulic Rams

*

*

Loading...

Loading...