Jetson

www.JetsonHVAC.com

43

Variable Flow

FWCD Series chillers can be applied in

variable flow applications where the flow is

varied and controlled by others. The flow

being delivered to the chiller must not go

outside the stated minimum and maximum

flow rates in General Data Table. Also, the

chilled water system volume should be

calculated using the highest evaporator flow

rate to be delivered to the chiller, and the rate

of change in flow rate must not exceed 10% of

design flow gpm per minute.

Water Circuit Requirements

FWCD Series modular chillers are equipped

with brazed plate evaporators. The water/fluid

circuits to be used with these chillers should be

designed and installed following sound

engineering practices and procedures as well

as any applicable local and industry standards.

For the brazed plate heat exchanger circuits,

focus on proper filtration and water quality is

necessary. Prior to connecting a FWCD Series

modular chiller into a newly installed or

existing water piping system, it is required to

flush the system with a detergent and hot water

mixture to remove previously accumulated dirt

and other organics. In old piping systems with

heavy encrustation of inorganic materials, a

water treatment specialist should be consulted

for proper passivation and/or removal of these

contaminants.

Filtration

Particulate fouling is caused by suspended

solids (foulants) such as mud, silt, sand or

other particles in the heat transfer medium. The

best way to avoid particulate fouling is to have

good water treatment and keep all system

water clean and with open loop system water,

maintain proper bleed rates and make up water.

A strainer with a 20-mesh screen (or screen

with 0.5 mm sized openings or less) is required

to be installed at the individual compact chiller

(or compact chiller array) inlet to protect the

brazed plate heat exchangers. Wye-strainers

are available as a factory-provided, field-

installed option. If an application is highly

susceptible to foulant contamination,

additional filtration methods should be

investigated.

Water quality

Poor water quality can cause another type of

fouling called scaling. Scaling is caused by

inorganic salts in the water circuit of the heat

exchangers. Scaling increases pressure drop

and reduces heat transfer efficiency. The

likelihood of scaling increases with increased

temperature, concentration and pH. In addition

to scaling, poor water quality can cause other

issues like biological growths and corrosion.

Therefore, water quality and water quality

control need to be an application consideration.

Please review the water quality requirements

for use with the brazed plate heat exchangers

on the FWCD Series modular chiller.

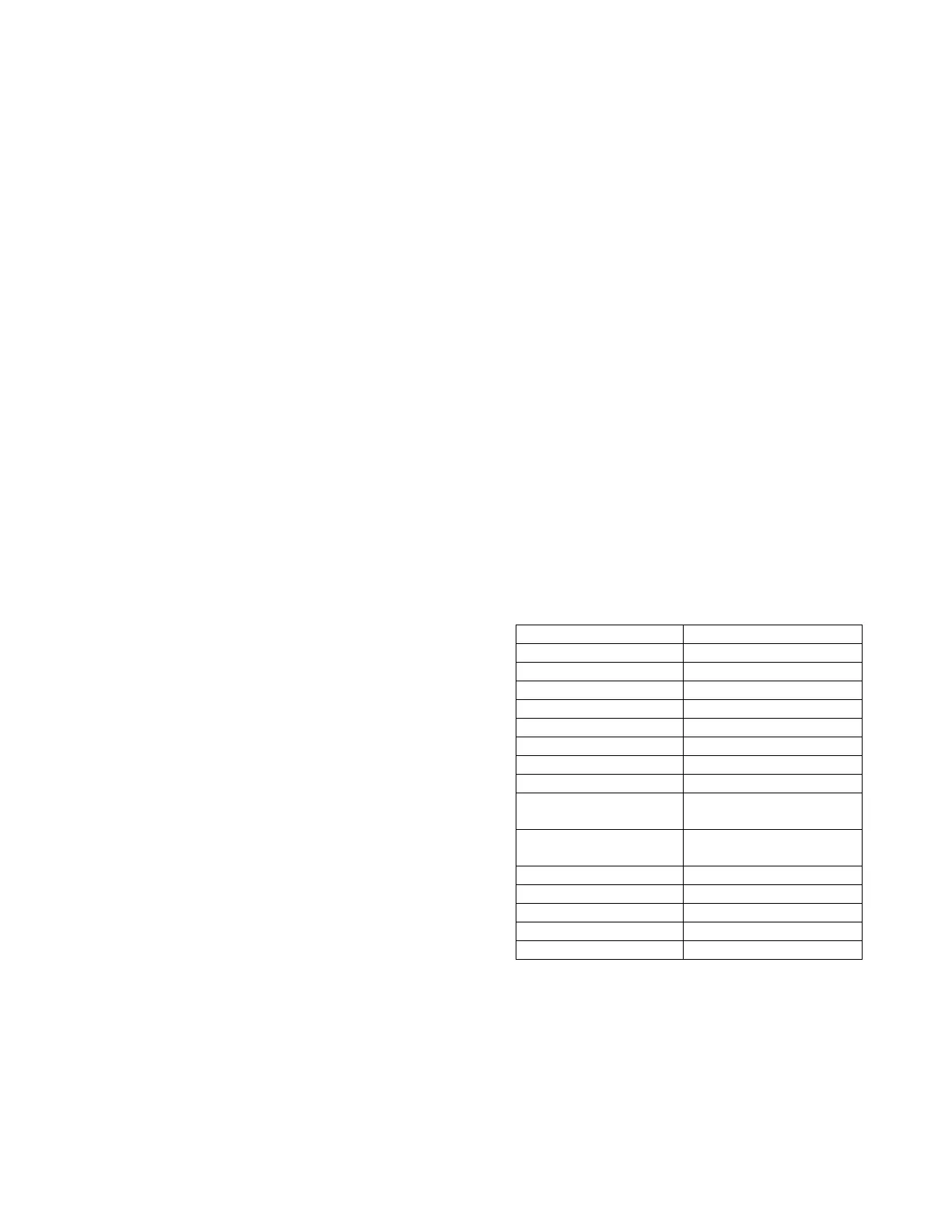

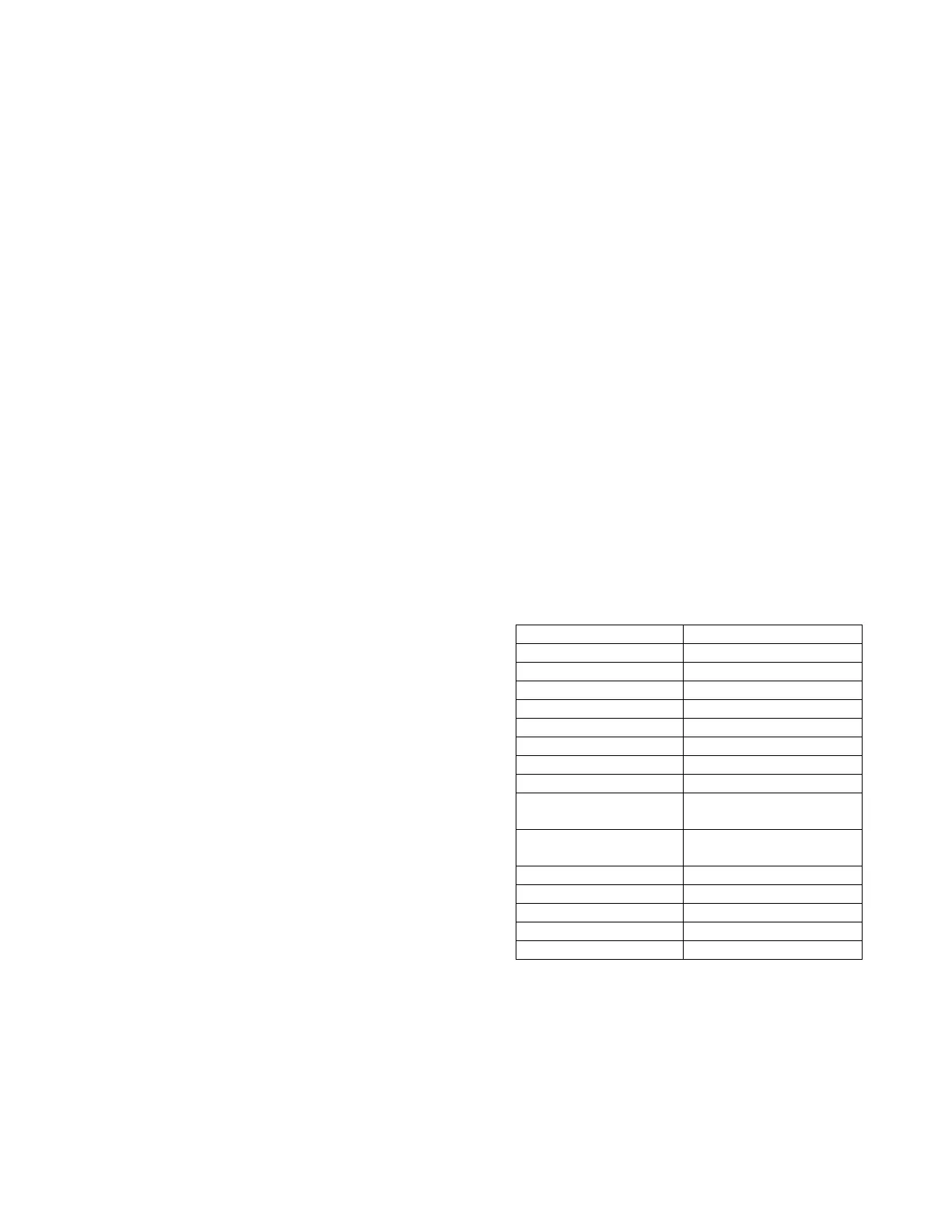

Table 8 Water Property Limits

Loading...

Loading...