This same detailed equation can be generalized

to another common loop volume sizing

method: loop time. As a general guideline, a

minimum 3-minute loop time is required for

the evaporator chilled water system. In a

typical water-cooled application, the nominal

fluid flow through the evaporator is 2.4

gpm/ton.

At nominal flows, a 3-minute loop time is

equivalent to a minimum loop volume of 7.2

gallon/ton (2.4 gpm/ton x 3 min = 7.2

gallon/ton) and would have an allowable

leaving fluid temperature swing of +/- 4.2°F

At nominal flows, a 2-minute loop time is

equivalent to a minimum loop volume of 4.8

gallon/ton. (2.4 gpm/ton x 2 min = 4.8

gallon/ton) and would have an allowable

leaving fluid temperature swing of +/- 6.25°F.

Notice, in the preceding example, if this

system was selected for a 45°F leaving water

temperature, the temperature will vary

between 42°F to 48°F (recall the variation

tolerance +/- 3°F) with the cycling of the

compressors at the water loop volume of 641

gallons. The final selection should ensure the

leaving water temperature does not drop below

42°F (or 40°F if using a high-capacity

evaporator). If a leaving water temperature

below 42°F (or 40°F if using a high-capacity

evaporator) is indicated then the loop volume

should be increased or glycol should be

included with the design.

Glycol

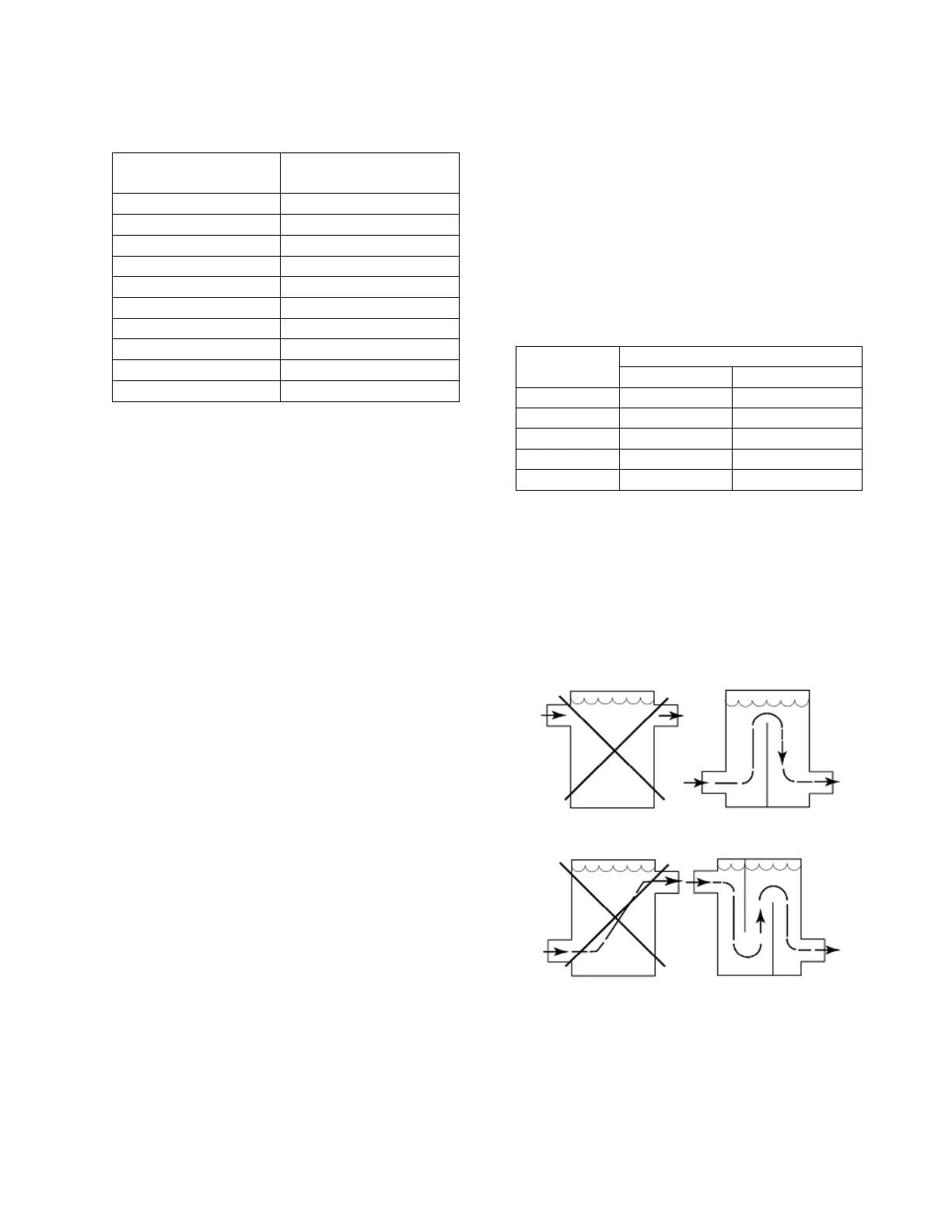

If the fluid loop contains glycol, the required

water loop volume should be multiplied by the

correction factor in Table 3.

Table 7 Glycol Correction Factors

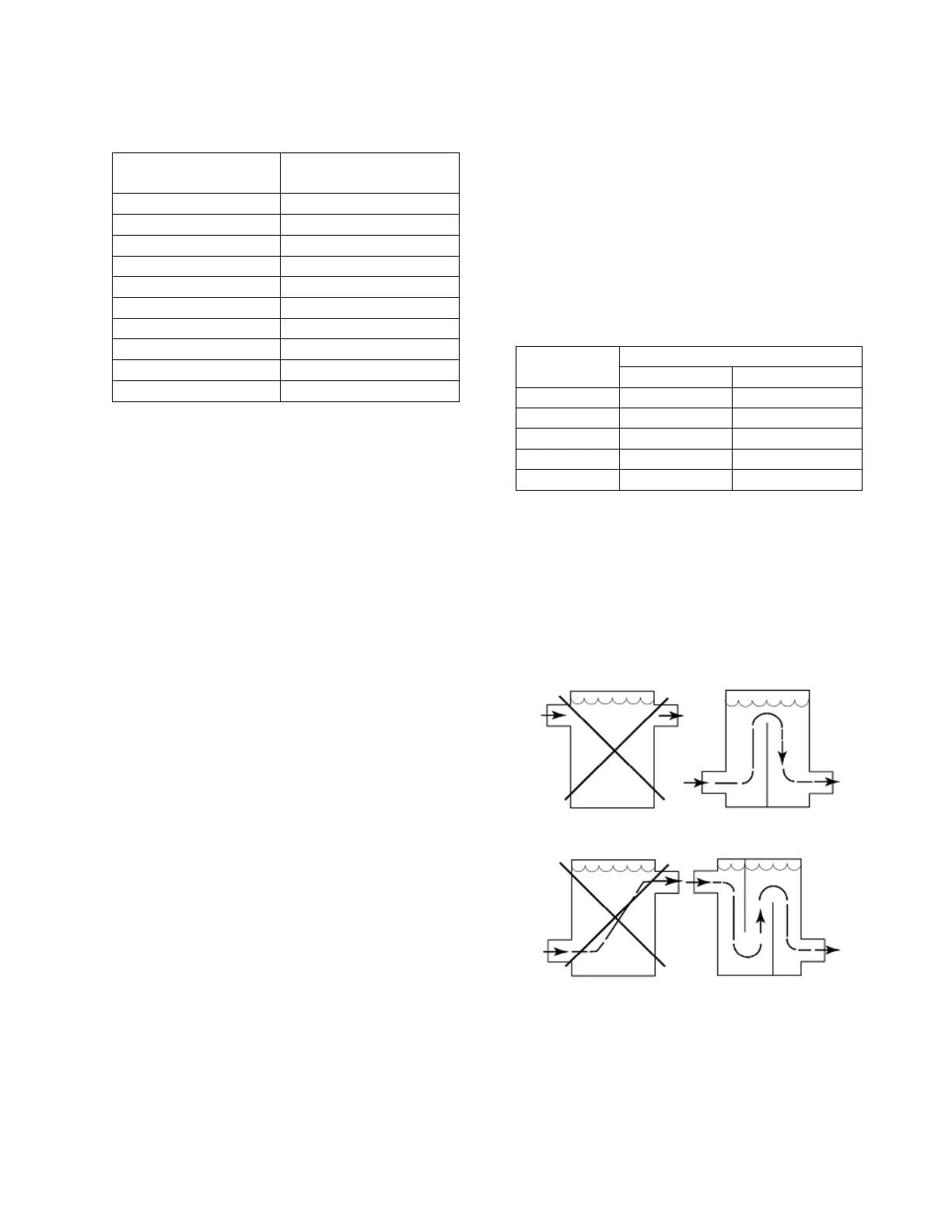

It may be necessary to install a storage tank in

the system to provide the necessary volume for

close temperature control. When this is done,

the tank should be installed in the loop between

the fluid leaving from the chiller and the

supply to the building. Figure A1 illustrates a

proper expansion tank usage.

Figure 14 Expansion Tank Usage

Loading...

Loading...