Jetson

www.JetsonHVAC.com

41

variable primary flow and motorized isolation

valves on each chiller module.

The FWCD Series chillers contain 2

compressors per module, and can be

configured in arrays containing up to 20

compressors. Use the following example as a

guide to determine swing in fluid temperature

tolerable.

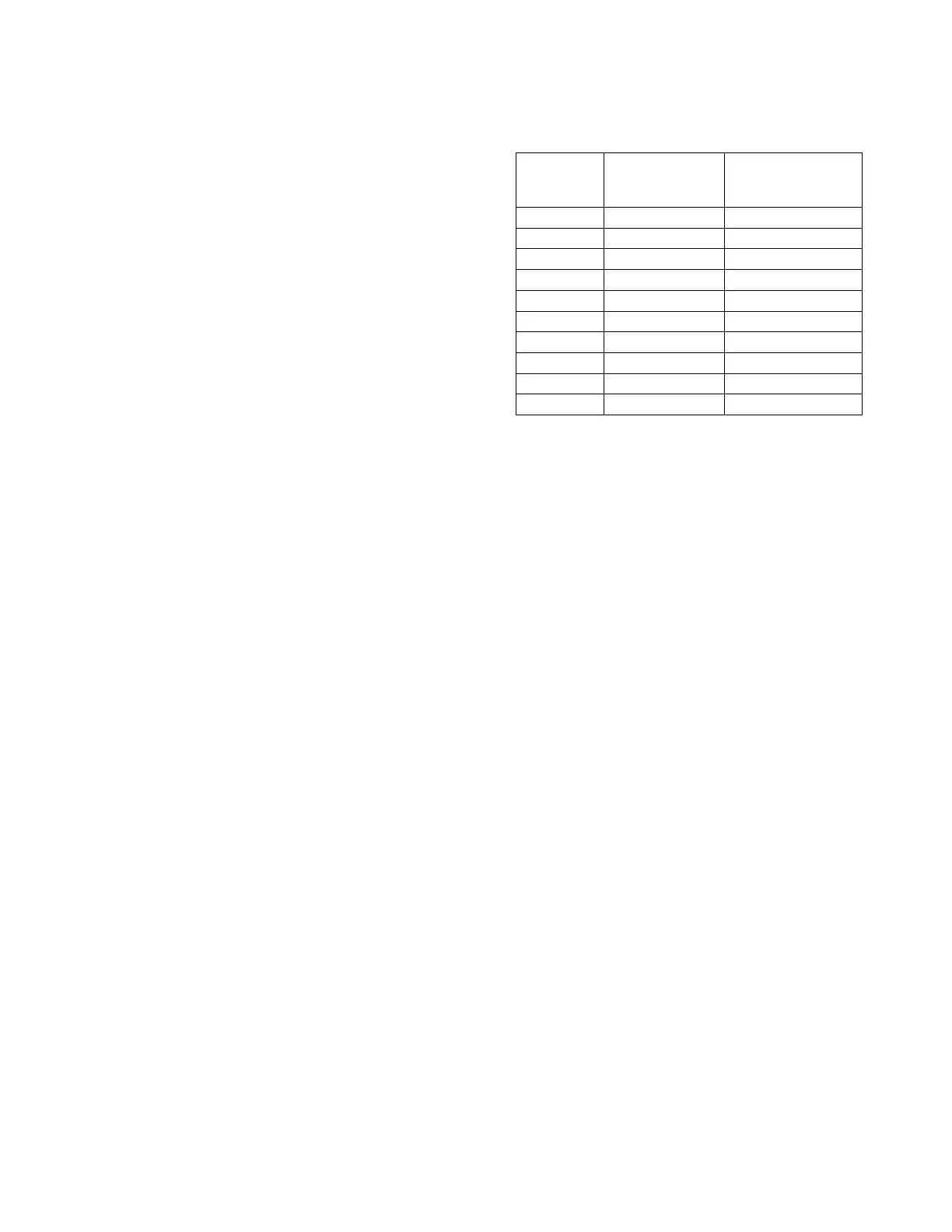

Use the information in Table 1 that lists the

maximum step of capacity in each array and a

factor for that model.

FLUID VOLUME EXAMPLE

Problem: An array of three (3) FWCD 45-ton

units has a total rated tonnage of 42.7 x 3 =

128.1 tons at the operating conditions. The

chilled water flow is constant volume. It is

desired to have no greater than a +/- 3°F

leaving water temperature variation due to

compressor unloading. What is the minimum

water volume required in the chilled water

loop?

Solution: We use the following equation to

determine the minimum allowable water loop

volume.

Minimum Water Loop Volume = Actual

Tons x (Min. Volume Gal-°F Swing/Ton) /

Allowable °F Swing

Allowable °F Swing is specified in the problem

statement. With a tolerance of +/- 3°F, the total

allowable swing is 6°F.

We select the value of Min. Volume Gal-°F

Swing/Ton from Table 5 Minimum Volume

based on the number of modules in the array

and the type of flow.

Table 5 Minimum Volume

* 25% is the lowest capacity step allowed for constant

flow arrays.

For a constant flow system, the minimum

capacity step is 25%, therefore the Minimum

Volume = 30 (Gal - °F deg F Swing)/ton

Thus, we can compute the minimum water

loop volume with the known performance of

128.1 tons of cooling at the application

conditions:

Minimum Water Loop Volume = 128.1 tons x

(30 Gal - °F Swing)/ton / 6 °F swing = 641

gallons.

Using the minimum turndown of 25% for

constant volume systems, this equation can be

generalized to a commonly used guideline:

gallons per ton loop volume. By tabularizing

different allowable °F swings the minimum

volume on a gallon per ton basis can be

displayed.

Loading...

Loading...