Jetson

www.JetsonHVAC.com

40

heat from the condenser that would otherwise

be wasted.

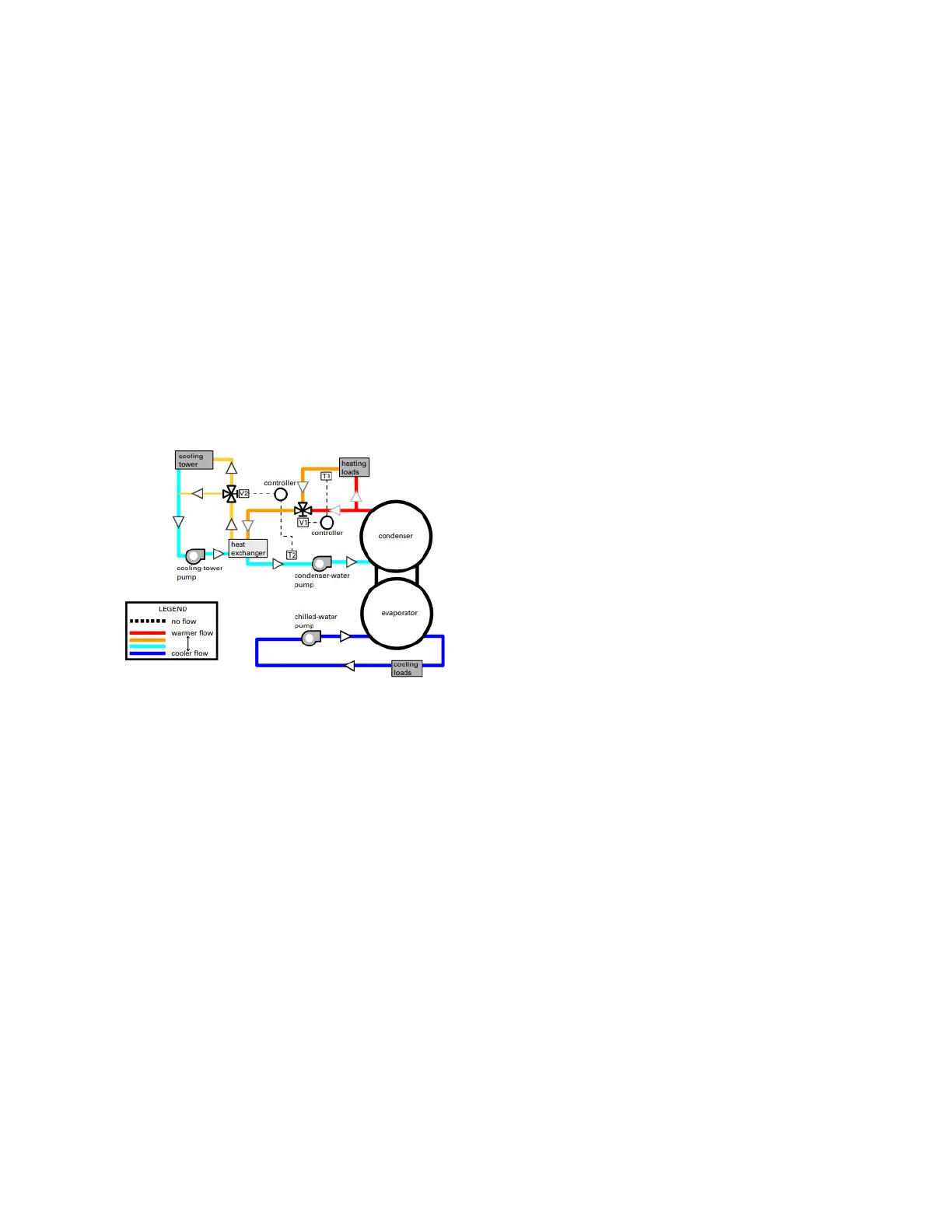

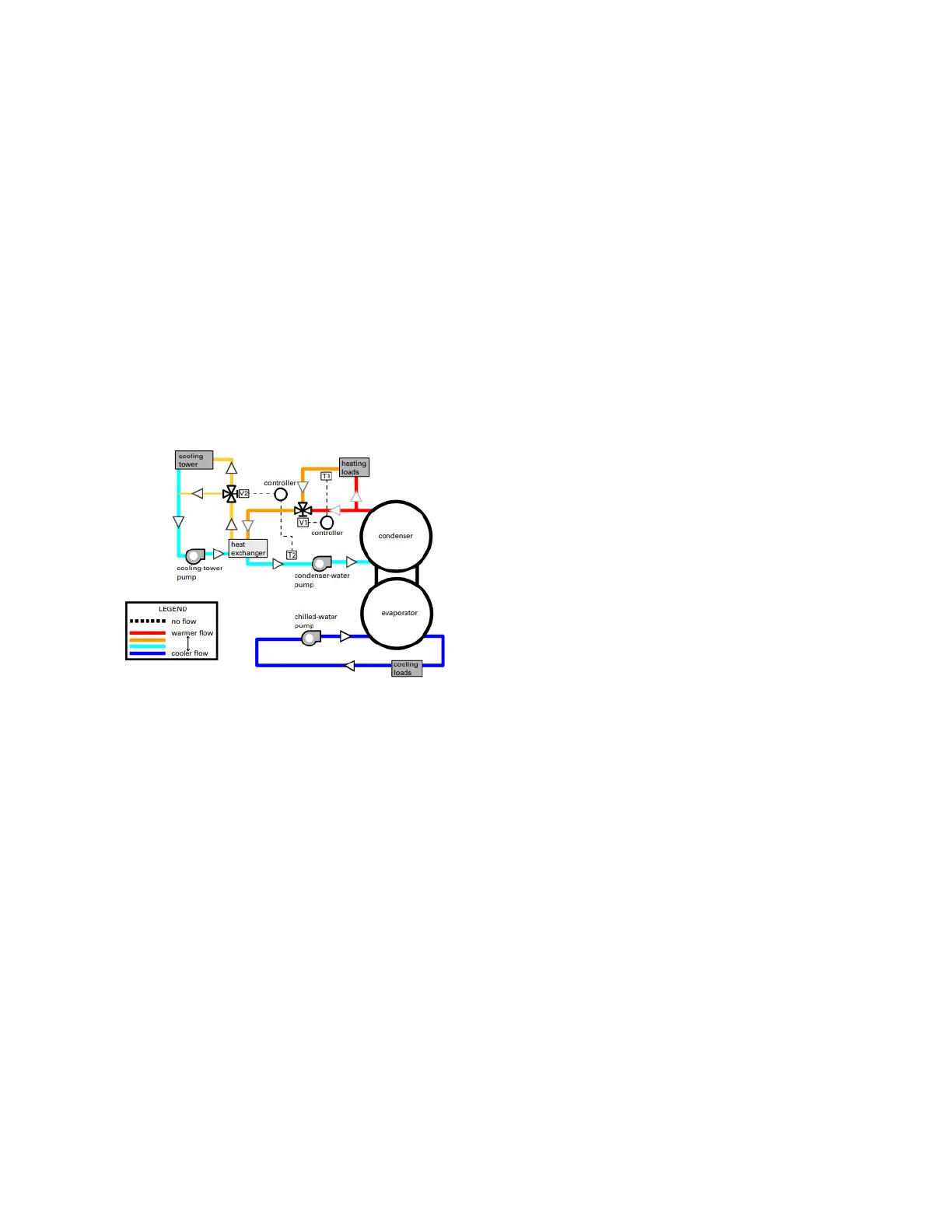

The use of heat recovery should be considered

in any building with simultaneous heating and

cooling requirements or in facilities where heat

can be stored and used at a later time. Buildings

with high year-round internal cooling loads are

excellent opportunities for heat recovery. Heat

recovery can be accomplished with the FWCD

Series by recovering heat from the water

leaving the standard condenser and using it in

conjunction with a third-party heat exchanger

as shown in Figure 13 - Heat Recovery.

Figure 13 - Heat Recovery

Heat recovery is designed to capture a portion

of the heat that is normally rejected to the

cooling tower and put it to beneficial use. With

the addition of a heat recovery cycle, heat

removed from the building cooling load can be

transferred to any heating application. The heat

recovery cycle is only possible if a cooling

load exists to act as a heat source.

The FWCD Series chiller uses smart control

logic to switch the control point between the

cooling set point and heating set point, based

on the smaller of the loads. This allows the

machine to operate in heat recovery mode

longer - maximizing the energy saved. In the

heat recovery cycle, the unit can control to a

hot water set point. During the heat recovery

cycle, the unit operates just as it does in the

cooling-only mode except that the leaving hot

water is the control point instead of the leaving

chilled water. Water circulated through the

heat recovery heat exchanger (condenser)

absorbs cooling load heat from the compressed

refrigerant gas discharged by the compressors.

The heated water is then used to satisfy heating

requirements.

Hospitals, dormitories, computer centers, and

hotels are opportunities for economical heat

recovery due to their needs for hot water for

reheat and domestic use, coupled with air-side

economizer operation, or in some cases, winter

operation of chillers. Heat recovery provides

hot water and tight control that minimizes

operating costs for the chilled water plant and

boiler/hot water heater, while also providing

consistent dehumidification. The heat recovery

heat exchanger cannot operate alone without a

load on the chiller.

Units with a brazed plate heat recovery heat

exchanger can produce up to 140°F leaving

water temperature and units with the shell and

tube heat recovery heat exchanger can produce

up to 125°F leaving temperature.

Fluid Volume

Consideration must be given to the total

volume of fluid in the system. In close coupled,

low volume systems, the leaving fluid

temperature will change quickly with steps of

capacity control. This is not acceptable if close

control is desired for a conditioned space or an

industrial process. In order to accurately

determine the fluid volume needed for the

application, you must resolve and agree on the

amount of swing in fluid temperature that can

be tolerated. This will depend on the control

system, the terminal equipment operation, and

use. For applications utilizing constant flow

evaporators, 25% of the design load is the

minimum array turndown allowed. If further

turndown is required, the system must have

Loading...

Loading...