1)

Thread

take-up.^ring

When

fine cotton thread or synthetic

threads

(tetoron,

nylon

eic.)arc

used,

the

tension

of the

take-up

spring

may

become

too

strong

or

the

range

of

movement

of

the

spring

may

become

too

wide,

causing

skip-stitching

just

before

the

machine

stops

and

sometimes

the

machine

does

not

trim

the

thread.

Be

extremely

careful.

2) Adjusting the first thread tension disc

*When

the tension of the first thread tensionis madestronger, the thread remaining at the tip of

the

needle

eye

becomes

shorter

after

trimming

and

when

it is

made

weaker,

the

remaining

thread

becomes

longer.

*For fine threads(synthetic

fiber),

weaken

the tensionand for thick thread,

make

it stronger.

3) Adjusting the second thread tension

*

Normally,

the adjustment of this

disc

is

same

as any other lockstitching

machines.

*

However,

please

note

that

when

synthetic

thread

is

used,

if the

tension

is

adjusted

too

weak,

the thread might break at the start of sewing.

4) Adjusting the

bobbin

thread

tension.

The

adjustment

of the

bobbin

thread

tension

is

practically

same

as

any

conventional

lockstitch

ing

machine.

However,

if the

tension

istoo

weak,

the

bobbin

might

spin

idly

at the

trimming

instant,

causing

the

needle

thread

to

"float"

up

at

the

start

of

sewing,

and

for

synthetic

threads,

thread

breakage

or

slipping

out of

the

needle

thread

at thestartof

sewing

might

occur.

Be

very

careful.

*

As

a rule, this

machine

is

used

with a bobbin

case

in

which

a

magnet

is built-in to

prevent

idle

spinning

of the

bobbin.

(Part

number

is D

1837555

BAO

and

sold

separately)

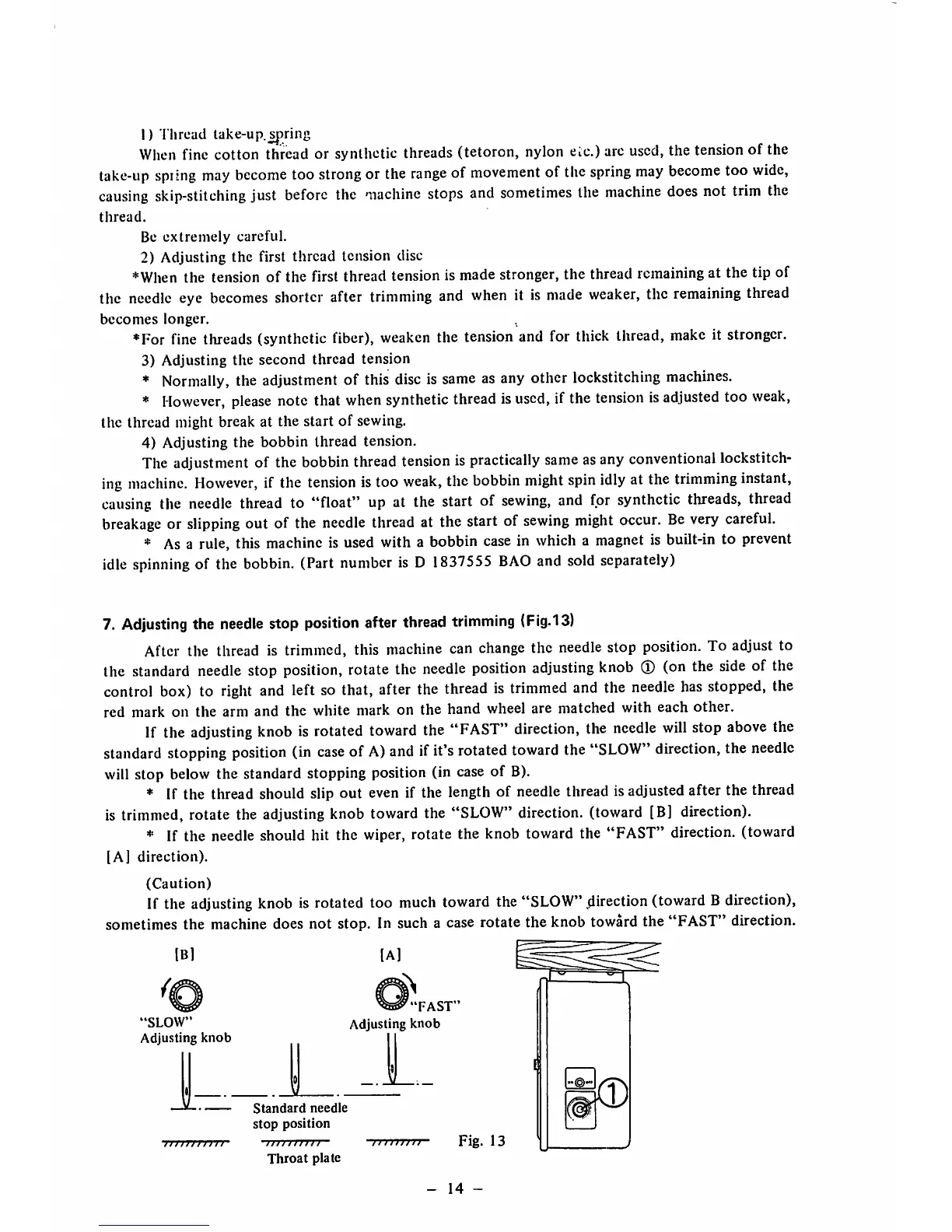

7.

Adjusting

the

needle

stop

position

after

thread

trimming

(Fig.13)

After

the thread is

trimmed,

this

machine

can

change

the

needle

stop

position.

To adjust to

the

standard

needle

stop

position,

rotate the

needle

position

adjusting

knob

(I)

(on the

side

of the

control

box)

to

right

and

left so that, after the

thread

is

trimmed

and

the

needle

has

stopped,

the

red mark on the arm and the white mark on the hand wheel are matched with each other.

If the

adjusting

knob

is

rotated

toward

the

"FAST"

direction,

the

needle

will

stop

above

the

standard

stopping

position

(in

case

of

A)

and

ifit's

rotated

toward

the

"SLOW

direction,

the

needle

will stop below the standard stopping position (in case of B).

* If the thread should slip out even if the length of needle thread isadjustedafter the thread

is trimmed, rotate the adjusting knob toward the

"SLOW"

direction, (toward [B] direction).

* If the needle should hit the wiper, rotate the knob toward the "FAST" direction, (toward

[A]

direction).

(Caution)

If the

adjusting

knob is rotated too

much

toward

the

"SLOW"

direction (toward Bdirection),

sometimes the machine does not stop. In such a case rotate the knob toward the "FAST" direction.

IB)

"SLOW"

Adjusting

knob

)iiiii)ii)i

[A]

^^"FAST"

Adjusting

knob

Standard

needle

stop

position

i/mmn

Throat

plate

Fig.

13

-

14

-

Loading...

Loading...