2.

Adjusting

the

position

of

the

moving

knife

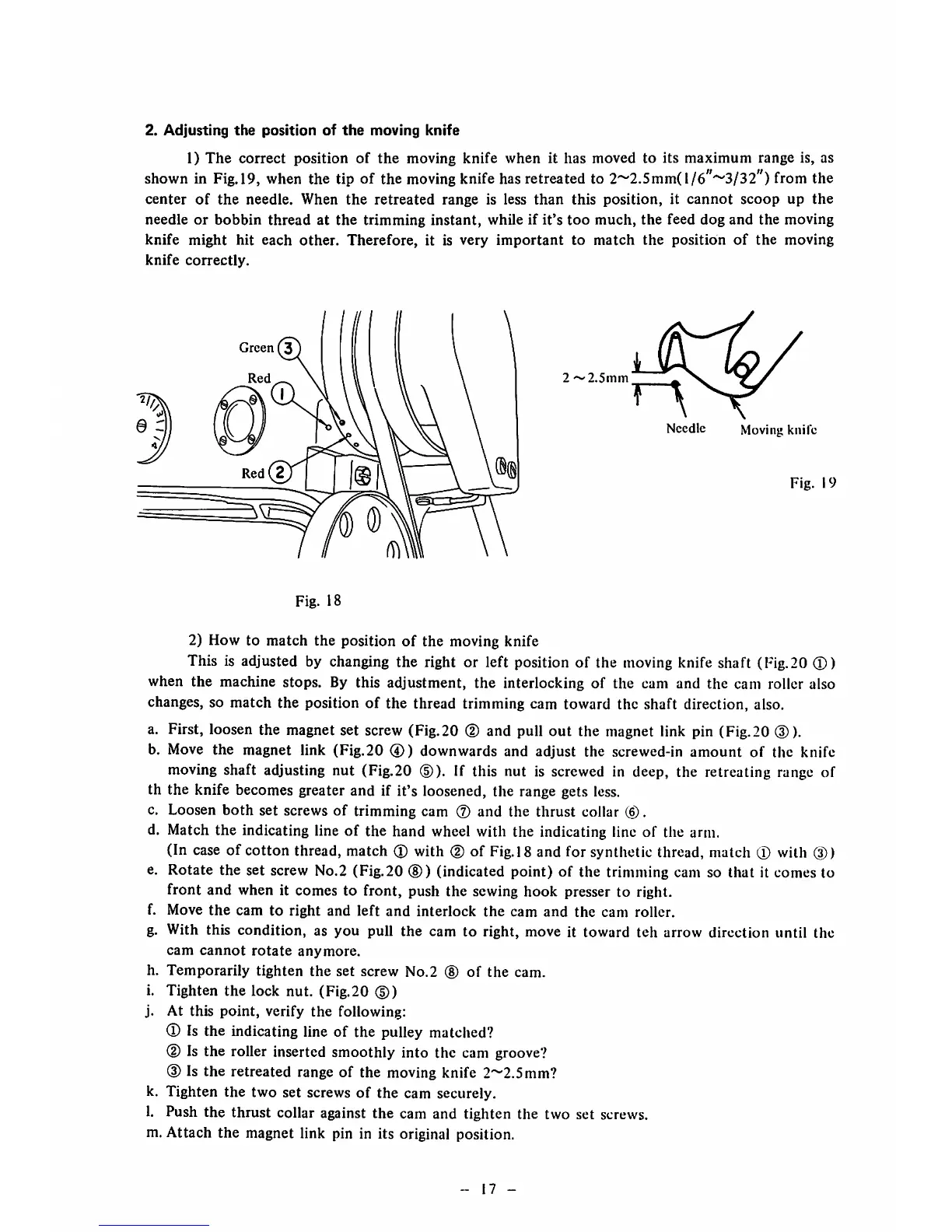

1)

The

correct

position

of

the

moving

knife

when

it

has

moved to

its

maximum

range is, as

shown

in Fig.l9,

when

the tip of the

moving

knifehasretreated to 2~2.5mm(l/6"~3/32")

from

the

center

of

the

needle.

When

the

retreated

range

is less

than

this

position,

it

cannot

scoop

up

the

needle

or

bobbin

thread

at

the

trimming

instant,

while

if

it's

too

much,

the

feed

dog

and

the

moving

knife

might

hit

each

other.

Therefore,

it is

very

important

to

match

the

position

of

the

moving

knife

correctly.

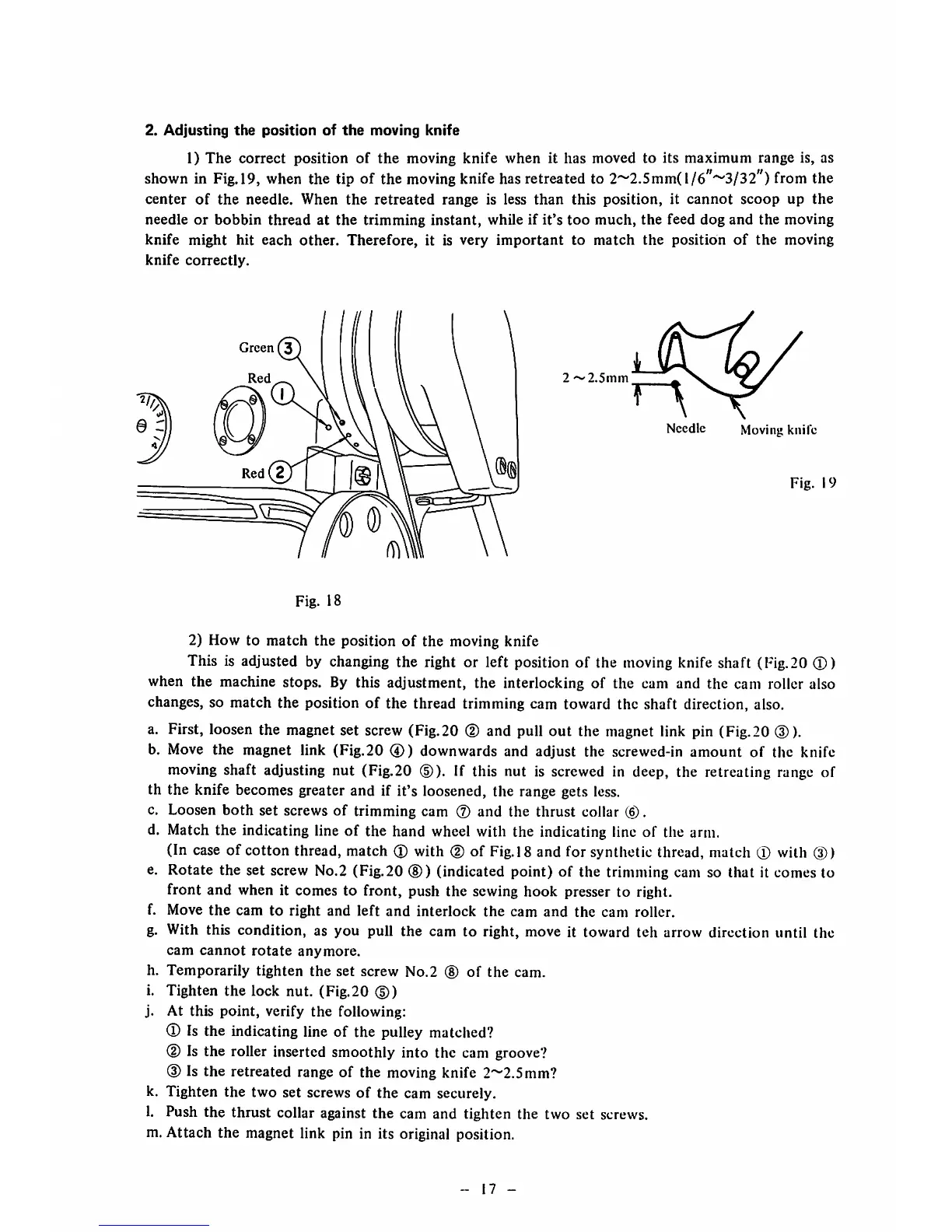

Green

2

~2.5mm

Needle

Moving

knife

Fig. 19

Fig. 18

2) How to match the position of the moving knife

This is adjusted by changing the right or left position of the moving knife shaft (Fig.20

®)

when the machine stops. By this adjustment, the interlocking of the cam and the cam roller also

changes, so match the position

of

the thread trimming cam toward the shaft direction, also.

a. First, loosen the magnet set screw (Fig.20 (D and pull

out

the magnet link pin (Fig.20 (D).

b. Move the magnet link (Fig.20 (£)) downwards and adjust the .screwed-in

amount

of the knife

moving shaft adjusting nut (Fig.20 (D). If this nut is screwed in deep, the retreating range of

th the knife becomes greater and if it's loosened, the range gets less.

c. Loosen

both

set screws of trimming cam

(7)

and the thrust collar (6).

d. Match the indicating line of the hand wheel with the indicating line of the arm.

(In case of cotton thread, match (D with

(2)

of Fig.18 and for synthetic thread, match (D with

(3))

e. Rotate the set screw No.2 (Fig.20

®)

(indicated point) of the trimming cam so that it comes to

front and when it comes to front, push the sewing hook presser to right.

f. Move

the

cam to right and left

and

interlock

the

cam

and

the

cam roller.

g. With this condition, as you pull the cam to right, move it toward teh arrow direction until the

cam

cannot

rotate

anymore.

h.

Temporarily

tighten

the

set

screw

No.2

(D

of

the

cam.

i.

Tighten

the

lock

nut.

(Fig.20

(D)

j. At this

point,

verify

the

following:

(D

Is the indicating line of the pulley matched?

(2)

Is

the

roller inserted smoothly into the cam groove?

(D Is the retreated range of the moving knife 2~2.5mm?

k. Tighten the two set screws

of

the cam securely.

1.

Push the thrust collar against the cam and tighten the two set screws,

m. Attach the magnet link pin in its original position.

-

17

-

Loading...

Loading...