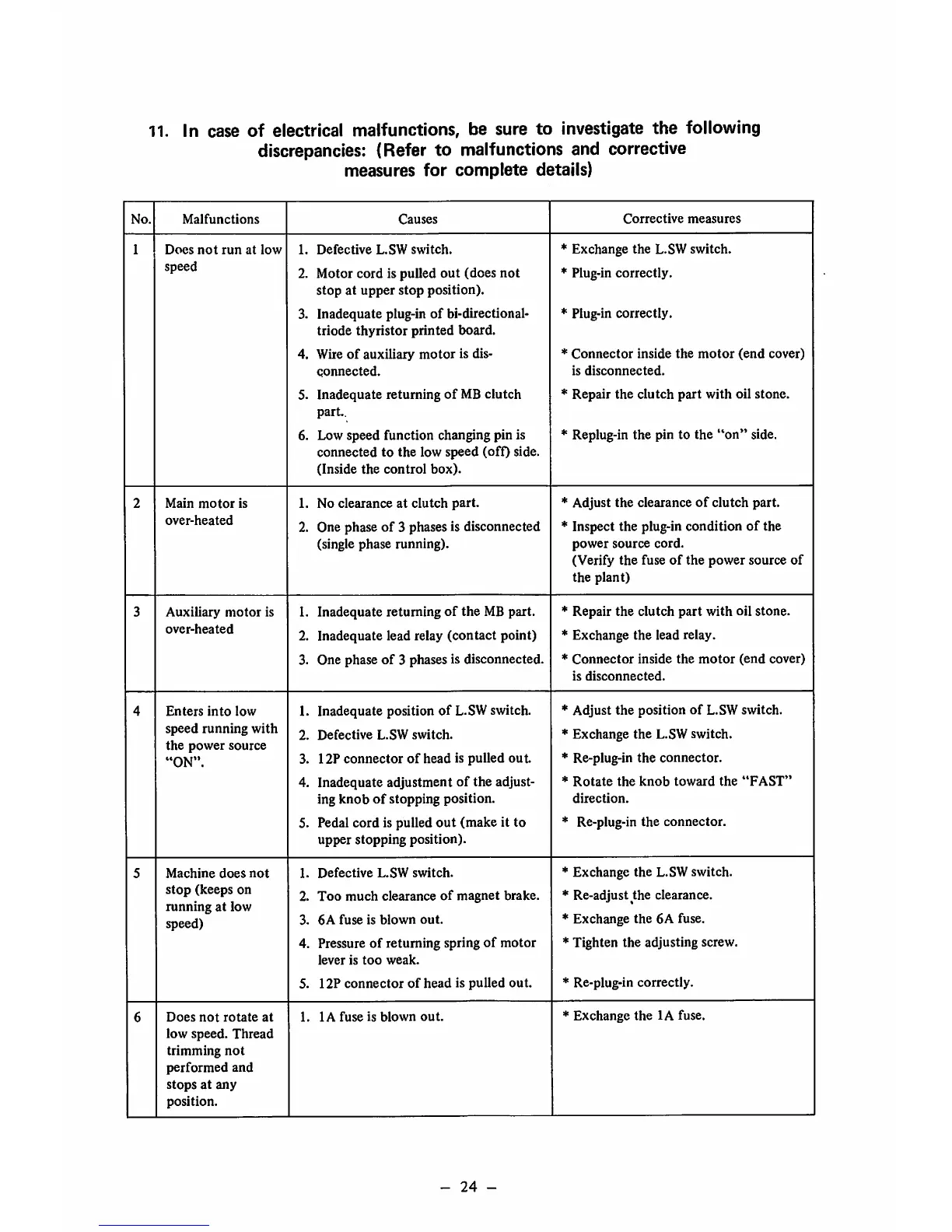

11. In case

of

electrical malfunctions, be sure

to

investigate

the

following

discrepancies: (Refer to malfunctions and corrective

measures for

complete

details)

No.

Malfunctions

Causes

Corrective

measures

1

Does

not

run

at

low

speed

1.

Defective

L.SW

switch.

2. Motor cord is pulled

out

(does

not

stop at upper

stop

position).

3. Inadequate plug-in

of

bi-directional-

triode

thyristor

printed

board.

4. Wire

of

auxiliary

motor

is dis

connected.

5. Inadequate returning

of

MB

clutch

part..

6. Low speed function changing pin is

connected to the low speed (ofO side.

(Inside

the

control

box).

* Exchange the L.SW switch.

* Plug-in

correctly.

* Plug-in correctly.

*

Connector

inside

the

motor

(end

cover)

is

disconnected.

* Repair

the

clutch

part

with oil stone.

* Replug-in the pin to the

"on"

side.

2

Main

motor

is

over-heated

1. No

clearance

at

clutch

part.

2. One phase

of

3 phases is disconnected

(single phase running).

* Adjust

the

clearance

of

clutch part.

* Inspect the plug-in condition

of

the

power

source cord.

(Verify

the

fuse

of

the

power

source

of

the

plant)

3

Auxiliary

motor

is

over-heated

1. Inadequate returning

of

the MB part.

2. Inadequate lead relay (contact point)

3. One phase

of

3 phases is disconnected.

* Repair the clutch part with oil stone.

* Exchange

the

lead relay.

*

Connector

inside

the

motor

(end

cover)

is

disconnected.

4

Enters

into

low

speed

running

with

the

power

source

"ON".

1. Inadequate position

of

L.SW switch.

2.

Defective

L.SW

switch.

3. 12P

connector

of

head

is

pulled

out

4. Inadequate adjustment of the adjust

ing

knob

of

stopping position.

5. Pedal cord is pulled

out

(make it to

upper

stopping

position).

* Adjust the position

of

L.SWswitch.

* Exchange

the

L.SW switch.

* Re-plug-in

the

connector.

*

Rotate

the

knob

toward

the

"FAST"

direction.

* Re-plug-in

the

connector.

5

Machine

does

not

stop

(keeps

on

running

at low

speed)

1.

Defective

L.SW

switch.

2.

Too

much

clearance

of

magnet

brake.

3.

6A

fuse

is

blown

out.

4. Pressure of returning spring

of

motor

lever

is

too

weak.

5. 12P

connector

of

head

is

pulled

out.

* Exchange

the

L.SW switch.

* Re-adjust the clearance.

* Exchange the 6A fuse.

* Tighten the adjusting screw.

* Re-plug-in correctly.

6

Does

not

rotate

at

low speed.

Thread

trimming

not

performed

and

stops

at

any

position.

1.

lA

fuse

is

blown

out.

* Exchange

the

lA

fuse.

-

24

-

Loading...

Loading...