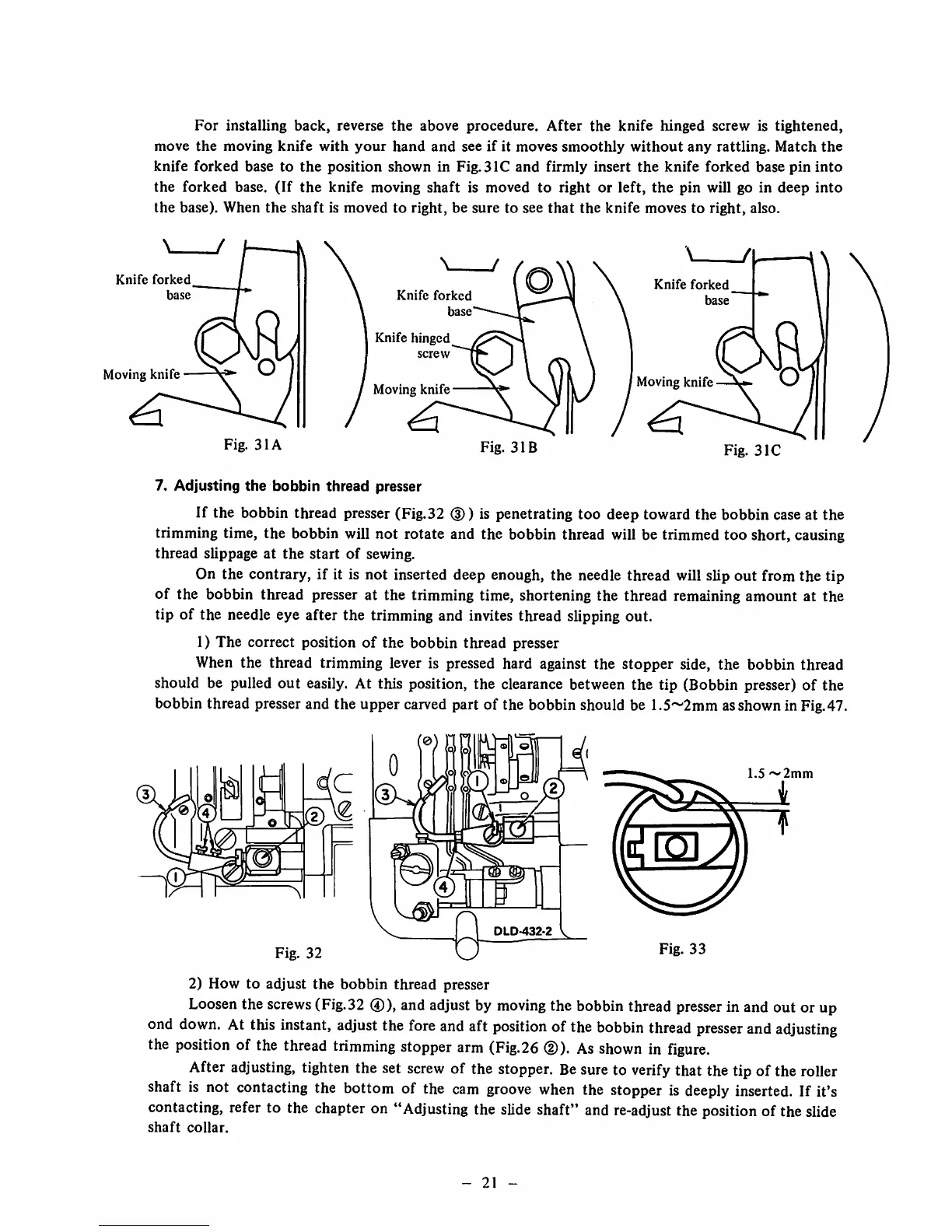

For

installing

back,

reverse

the

above

procedure.

After

the

knife

hinged

screw

is

tightened,

move

the

moving

knife

with

your

hand

and

see

if it

moves

smoothly

without

any

rattling.

Match

the

knife

forked

base to

the

position

shown

in

Fig.31C

and

firmly insert

the

knife

forked

base

pin

into

the

forked

base.

(If

the

knife

moving

shaft

is moved to right or

left,

the

pin will go in

deep

into

the

base). When

the

shaft

is

moved

to

right,

be

sure

to see

that

the

knife

moves

to

right,

also.

N (

Knife

forked

base

Moving knife

Fig.

31A

/

Knife

forked

base

Knife hinged

screw

Moving

knife

Fig.

31B

Knife

forked

base

Moving knife

Fig.

31C

7. Adjusting

the

bobbin

thread

presser

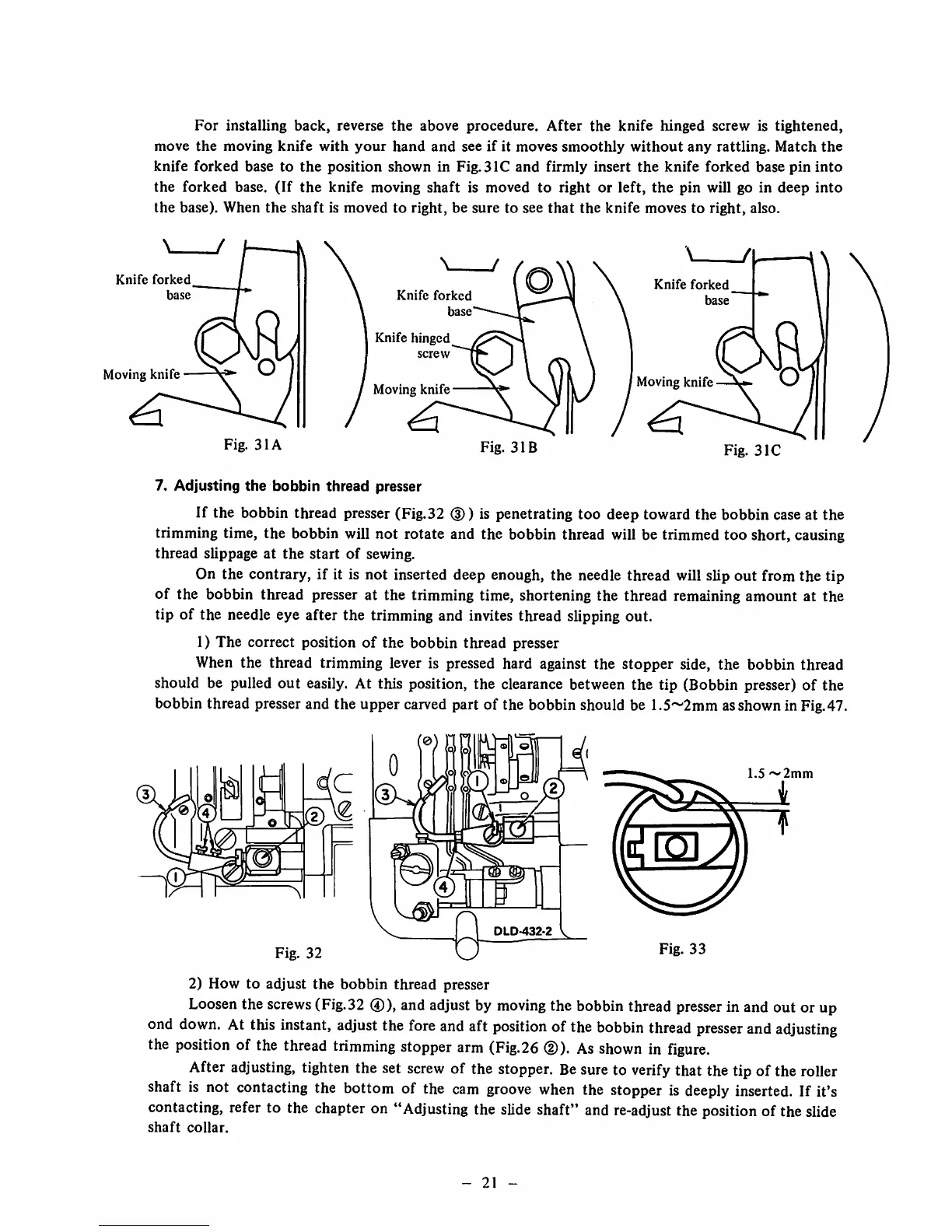

If the bobbin thread presser (Fig.32 (3)) is penetrating too deep toward the bobbin case at the

trimming time, the bobbin will not rotate and the bobbin thread will be trimmed too short, causing

thread

slippage at

the

start

of

sewing.

On the contrary, if it is not inserted deep enough, the needle thread will slip out from the tip

of the bobbin thread presser at the trimming time, shortening the thread remaining amount at the

tip of the needle eye after the trimming and invites thread slipping out.

1) The correct position of the bobbin thread presser

When the thread trimming lever is pressed hard against the stopper side, the bobbin thread

should be pulled out easily. At this position, the clearance between the tip (Bobbin presser) of the

bobbin thread presser and the upper carved part of the bobbin should be 1.5~2mm asshown in Fig.47.

a

1.5

~2mm

DLD-432'2

V

Fig.

32

Fig.

33

2) How to adjust the bobbin thread presser

Loosen

the

screws

(Fig.32 ®), and adjust by

moving

the bobbinthread

presser

in and out or up

ond

down.

At

this

instant,

adjust

the

fore

and

aft

position

ofthe

bobbin

thread

presser

and

adjusting

the

position

of the

thread

trimming

stopper

arm

(Fig.26

(D).

As

shown

in

figure.

After

adjusting,

tighten

the set

screw

of the

stopper.

Be

sure

to

verify

that the tip of the

roller

shaft is not contacting the bottom of the

cam

groove

when

the stopper is

deeply

inserted. If it's

contacting, refer to the chapteron "Adjusting the

slide

shaft" and

re-adjust

the positionof the

slide

shaft

collar.

-

21

-

Loading...

Loading...