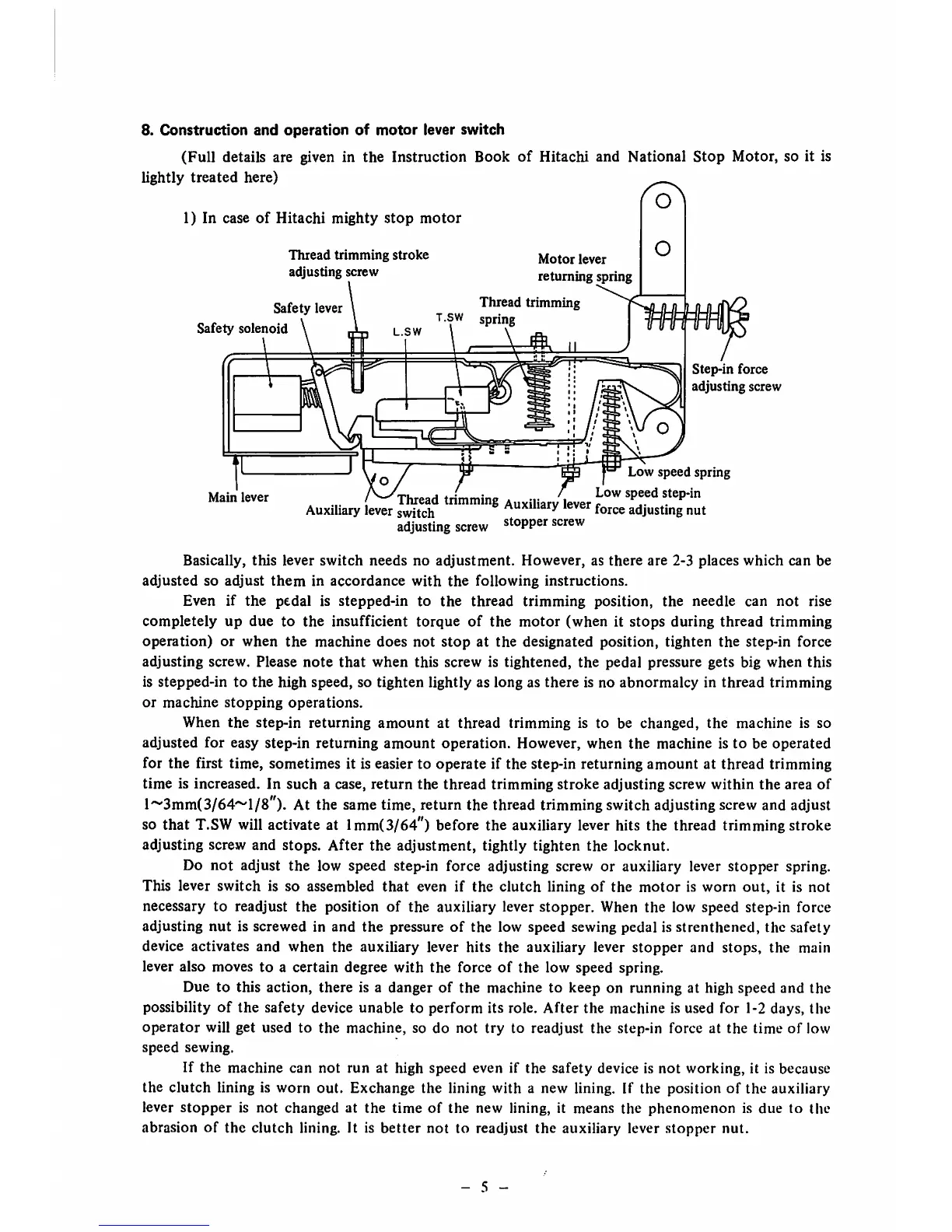

8.

Construction

and

operation

of

motor

lever switch

(Full

details are given in

the

Instruction

Book

of

Hitachi and National

Stop

Motor, so it is

lightly

treated

here)

1)

In

case

of

Hitachi

mighty

stop

motor

Thread

trimming

stroke

adjusting screw

Safety

lever

Safety solenoid

L.SW

Motor

lever

returning

spring

Thread

trimming

T.sw spring

- 5

Step-in force

adjusting screw

speed

spring

Main

lever

/^

Thread

trimming

Auxiliarv'lever

Auxiliary

lever

switch

Auxiliary

lever

force

adjusting

nut

adjusting

screw

stopper

screw

Basically,

this

lever

switch

needs

no

adjustment.

However,

as

there

are

2-3

places

which

can

be

adjusted

so

adjust

them

in

accordance

with

the

following

instructions.

Even if

the

pedal

is

stepped-in

to

the

thread

trimming

position,

the

needle

can

not

rise

completely

up

due

to

the

insufficient

torque

of

the

motor

(when

it

stops

during

thread

trimming

operation)

or

when

the

machine

does

not

stop

at the designated position,

tighten

the

step-in force

adjusting

screw. Please

note

that

when

this screw is

tightened,

the

pedal

pressure

gets

big

when

this

is

stepped-in

to

the

high speed, so

tighten

lightly as

long

as

there

is no

abnormalcy

in

thread

trimming

or

machine

stopping

operations.

When

the

step-in

returning

amount

at

thread

trimming

is to be

changed,

the

machine

is so

adjusted

for

easy

step-in

returning

amount

operation.

However,

when

the

machine

is

to

be

operated

for

the

first time, sometimes it is easier to operate if the step-in returning

amount

at thread trimming

time

is increased. In

such

a case,

return

the

thread

trimming

stroke

adjusting

screw

within

the

area

of

l~3mm(3/64~l/8"). At the sametime, return the thread

trimming

switchadjusting

screw

and adjust

so that

T.SW

will

activate at lmm(3/64") before the auxiliary lever hits the thread trimmingstroke

adjusting screw and stops.

After

the

adjustment,

tightly

tighten

the

locknut.

Do

not

adjust

the

low speed step-in force adjusting screw or auxiliary lever

stopper

spring.

This lever

switch

is so assembled

that

even if

the

clutch

lining

of

the

motor

is

worn

out,

it is

not

necessary

to

readjust

the

position

of

the

auxiliary lever

stopper.

When

the

low speed step-in force

adjusting

nut

is screwed in and

the

pressure

of

the

low speed sewing pedal is

strenthened,

the

safety

device activates and when the auxiliary lever hits the auxiliary lever

stopper

and stops, the main

lever also moves to a certain degree with the force of the low speed spring.

Due to this

action,

there

is a danger

of

the machine to

keep

on

running

at high

speed

and

the

possibility

of

the

safety

device

unable

to

perform

its role.

After

the machine is used for 1-2 days,

the

operator

will get used to the machine, so do

not

try

to readjust the step-in force at

the

time

of

low

speed

sewing.

If

the

machine can

not

run at high speed even if the

safety

device is

not

working, it is because

the

clutch

lining is worn

out.

Exchange the lining with a new lining. If the position of

the

auxiliary

lever

stopper

is

not

changed at

the

time

of

the

new lining, it means the

phenomenon

is

due

to the

abrasion

of

the

clutch

lining. It is

better

not to readjust the auxiliary lever

stopper

nut.

Loading...

Loading...