– 1 –

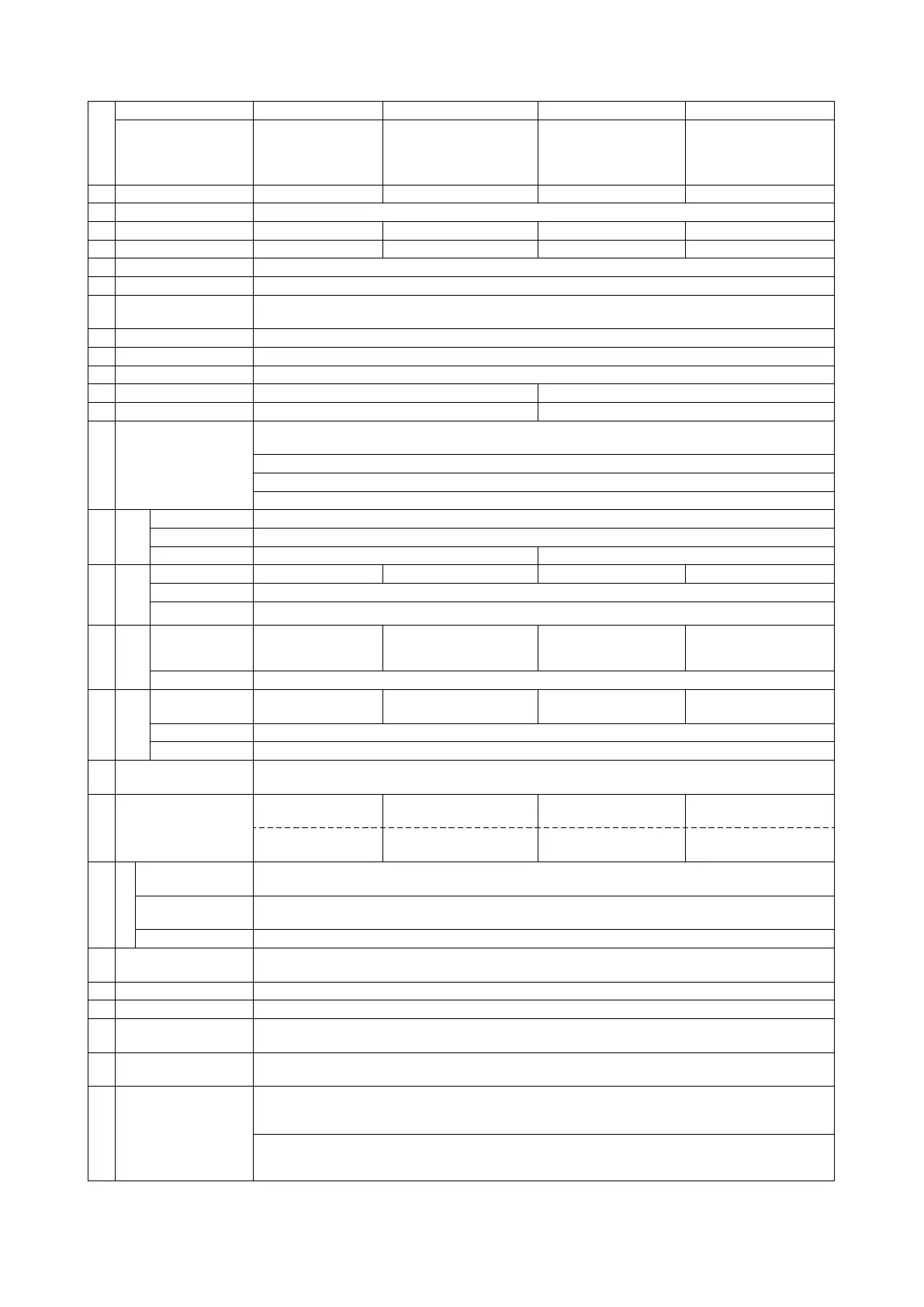

1. Specications

No.

Model DDL-9000C-SMS DDL-9000C-SSH DDL-9000C-FMS DDL-9000C-FSH

Item

Semi-dry for stan-

dard materials

(Digital type)

Minute-quantity lubrica-

tion for heavy-weight

materials

(Digital type)

Semi-dry

for standard

materials

(Full digital type)

Minute-quantity lubrica-

tion for heavy-weight

materials

(Full digital type)

1 Max. sewing speed 5000sti/min

*1

4500sti/min

*2

5000sti/min

*1

4500sti/min

*2

2 Max. stitch length Difference of stitch length 5 mm

3 Needle bar stroke 30.7mm 35mm 30.7mm 35mm

4 Take-up lever stroke 110mm 113mm 110mm 113mm

5

Thread trimming method

Double-edged rotary type

6

Lower bobbin winder unit

Built-in the machine head (with bobbin thread holding plate)

7

Needle thread nipper

unit

(

NB type

)

Electromagnetic

8 Horizontal feed control Electronic control

9 Vertical feed control Electronic control

10

Feed locus

4 kinds

11

Needle thread tension

Spring type Active tension

12 Presser foot pressure

Spring type

Electronic control

13 Number of patterns Sewing pattern : 99 patterns

(For the polygonal shape sewing, as many as 10 patterns can be registered.)

Cycle sewing pattern : 9 patterns

Custom-pitch pattern 20 patterns

Condensation custom pattern 9 patterns

14

Data com-

munication

NFC

With

USB

With

LAN

Without With

15

Lubrication

system

Plate (needle bar) Grease lubrication Oil wick lubrication Grease lubrication Oil wick lubrication

Hook Plunger pump type

Gearbox

Grease lubrication+Special surface processing

16

Oil supply

Plate (needle bar) Grease lubrication +

Special surface

processing

Oil wick lubrication Grease lubrication +

Special surface pro-

cessing

Oil wick lubrication

Hook With oil tank (capacity: 150 ml)

17

Oil to be

used

Plate (needle bar)

JUKI Grease A

(Part No.: 40006323)

No.1

or

7

*3

JUKI Grease A

(Part No.: 40006323)

No.1

or

7

*3

Hook

No.1 or 7

*3

Gearbox

JUKI Grease A (product No.: 40006323)

18 Lifting amount of

presser

By hand

:

5.5mm

、

By knee

:

15mm

Auto

:

1st step 5.0mm

(

*4

:

0.1

~

8.5mm

)

2nd step 8.5mm

(

*4

:

8.5

~

13.5mm

)

19 Needle

DB×1(#11)#9

~

18

1738 (Nm75) Nm65

to

110

DB×1(#21)#20

~

23

1738

(

Nm130

)

Nm125

to

160

DB×1(#11)#9

~

18

1738

(

Nm75

)

Nm65

to

110

DB×1(#21)#20

~

23

1738

(

Nm130

)

Nm125

to

160

DP×5(#11)#9

~

18

134

(

Nm75

)

Nm65

to

110

DP×5(#21)#20

~

23

134

(

Nm130

)

Nm125

to

160

DP×5(#11)#9

~

18

134

(

Nm75

)

Nm65

to

110

DP×5(#21)#20

~

23

134

(

Nm130

)

Nm125

to

160

20

Dimensions

From needle to

machine arm (width)

303mm

From needle to

machine arm (high)

137mm

Bed size 178mm×517mm

21

Machine head drive Compact AC servomotor

:

400W

that is directly connected to the main shaft

(

direct-drive system

)

22 Machine head weight 40.5kg

23 Power consumption 520VA

24 Working temperature

and humidity

Temperature: 5 °C to 35°C, humidity: 35% to 85% (No dew condensation permissible)

25 Supply voltage and

frequency

Rated voltage ±10%, 50/60Hz

26

Noise

SMS ;- Equivalent continuous emission sound pressure level (L

pA

) at the workstation:

A-weighted value of 81.5 dBA ; (Includes K

pA

= 2.5 dBA) ; according to ISO 10821- C.6.2

-ISO 11204 GR2 at 5,000 sti/min.

SSH ;- Equivalent continuous emission sound pressure level (L

pA

) at the workstation:

A-weighted value of 77.5 dBA ; (Includes K

pA

= 2.5 dBA) ; according to ISO 10821- C.6.2

-ISO 11204 GR2 at 4,500 sti/min.

*1

:

Stitch length

0.00

~

4.00

:

5,000sti/min,

stitch length

4.05

~

5.00

:

4,000sti/min

*2

:

Stitch length

0.00

~

4.00

:

4,500sti/min,

stitch length

4.05

~

5.00

:

4,000sti/min

*3

:

JUKI New Defrix Oil No. 1 or JUKI Machine Oil 7 (equivalent to ISO VG7)

*4

:

It's adjusted by a panel

Loading...

Loading...