– 12 –

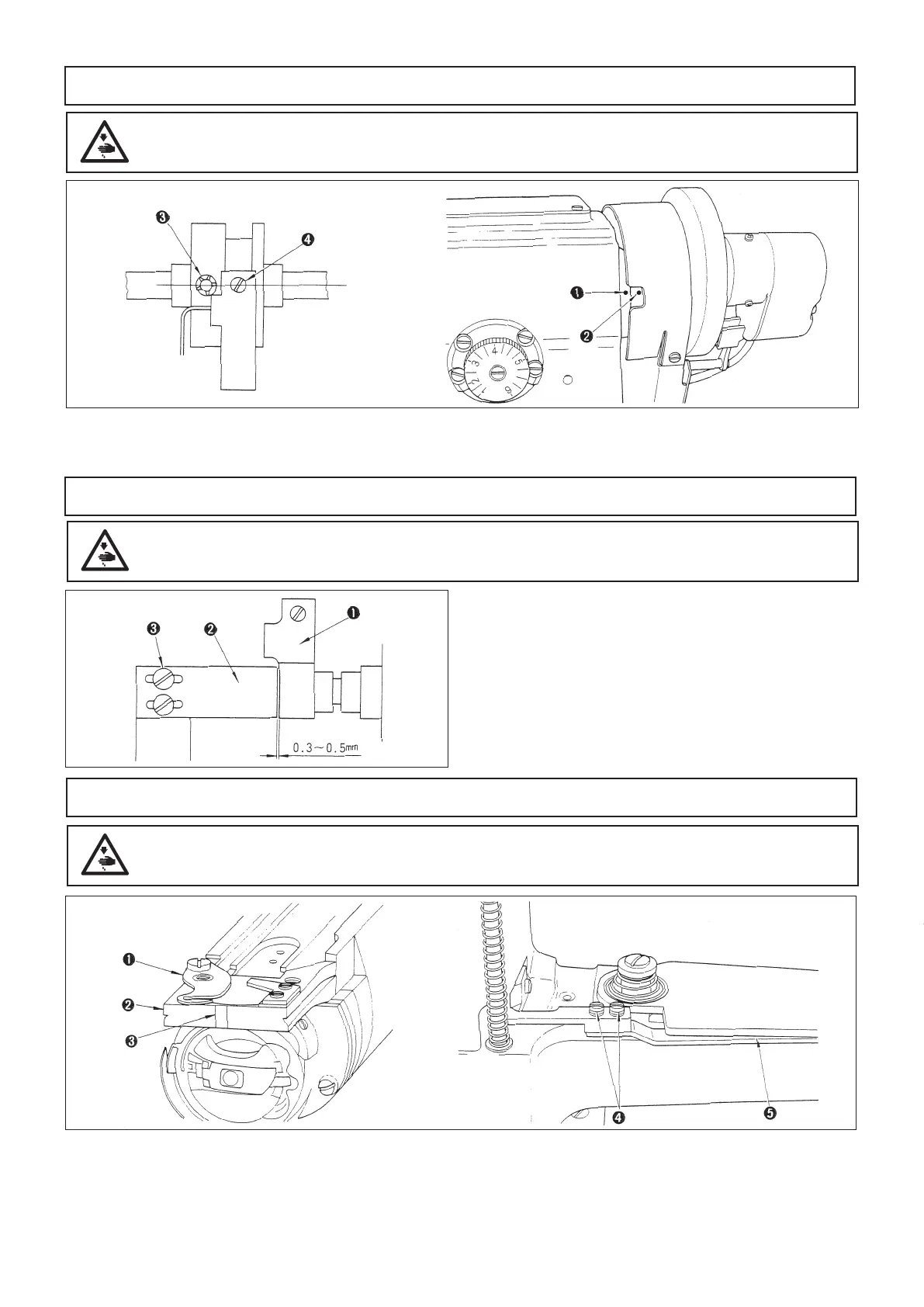

21.ADJUSTING THE THREAD TRIMMING CAM

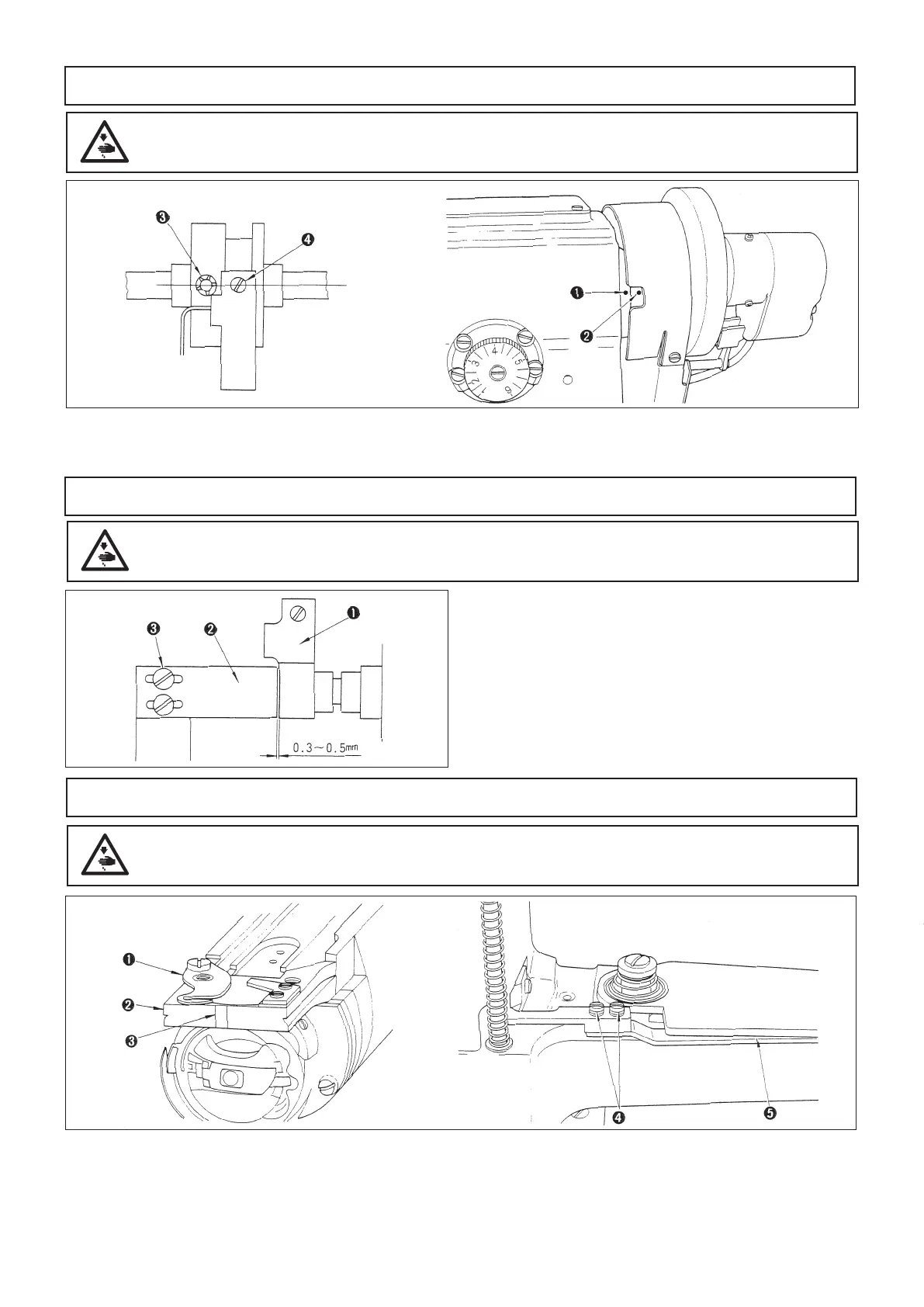

22.ADJUSTING THE CAM ROLLER ARM AND THE CAM ROLLER ARM PRESSER (DSC-245-4,-7, DSC-245V-4,-7)

23.ADJUSTING MAX MOVING STROKE OF THE ROTARY KNIFE (DSC-245-4,-7, DSC-245V-4,-7)

1

.

Turning the handwheel, align red marker dot

❶

in the machine arm with white marker dot

❷

in the hand wheel.

2

.

Turn the thread trimming cam until rst screw

❸

in the thread trimming cam aligns with cam roller shaft

❹

in

the cam roller arm,and tighten the screw at the aligned position.

1. Adjust clearance so as to be 0.3 to 0.5 mm between

cam roller arm

❶

and cam roller arm presser

❷

in

case of no thread trimming by loosening setscrew

❸

in the cam roller arm presser.

2. After adjustment,tighten the setscrew

❸

.

1

.

Turn the handwheel by hand and insert the trimmer. (When the needle comes down to its lower end, turn the

handwheel to actuate the thread trimmer while pushing the picker driving plate backwards.)

2

.

Loosen setscrew

❹

in the driving plate and adjust the length of driving plate

❺

so that the edge of the rotary

knife moves to marker line

❸

in the throat plate frame

❷

when the moving stroke of rotary knife

❶

is max.

○

Increasing the driving plate length will decrease the travel distance of the moving knife. Decreasing the driving

plate length will increase it.

Aligned

position

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

– 1 –

SPECIFICATIONS

Model DSC-245 DSC-245-4,-7 DSC-245V DSC-245V-4,-7

Type of sewing

machine head

Cylinder-bed,

1-needle,unison-feed

lockstitch machine

Cylinder-bed,

1-needle,unison-feed

lockstitch machine with

an automatic thread

trimmer

Cylinder-bed,

1-needle,unison-feed

lockstitch machine

(horizontal drop feed)

Cylinder-bed,

1-needle,unison-feed

lockstitch machine with

an automatic thread

trimmer (horizontal drop

feed)

Usage Suited for sewing medium weight materials

Sewing speed Max.2,200 sti/min

Stitch length 0 to 6 mm

Lift of presser

foot

Hand lifter 9 mm

Knee lifter 15 mm

Hand lifter 8 mm

Knee lifter 13 mm

Hand lifter 9 mm

Knee lifter 15 mm

Hand lifter 8 mm

Knee lifter 13 mm

Thread take-

up lever

Slide type thread take-up

Needle bar

stroke

36 mm

Needle to be

used

GROZ-BECKERT 135×17 Nm90 to Nm130 (Standard Nm110)

Needle system #50 to #20

Stitch adjusting

method

Dial

Lubrication

method

By an oiler. Only the hook is automatically lubricated by a plunger pump .

Motor to be

used

400W Electro-stop

motor (4P)

AC servo motor

400W Electro-stop

motor (4P)

AC servo motor

Oil to be used New Defrix Oil No.1

Noise - Equivalent

continuous emission

sound pressure

level (L

pA

) at the

workstation :

A-weighted value of

83.0 dB; (Includes

K

pA

= 2.5 dB);

according to ISO

10821- C.6.2 -ISO

11204 GR2 at 2,200

sti/min.

- Sound power level

(L

WA

) ;

A-weighted value of

89.5 dB; (Includes

K

WA

= 2.5 dB);

according to ISO

10821- C.6.2 -ISO

3744 GR2 at 2,200

sti/min.

- Equivalent

continuous emission

sound pressure

level (L

pA

) at the

workstation :

A-weighted value of

78.0 dB; (Includes

K

pA

= 2.5 dB);

according to ISO

10821- C.6.2 -ISO

11204 GR2 at 2,200

sti/min.

- Equivalent

continuous emission

sound pressure

level (L

pA

) at the

workstation :

A-weighted value of

83.0 dB; (Includes

K

pA

= 2.5 dB);

according to ISO

10821- C.6.2 -ISO

11204 GR2 at 2,200

sti/min.

- Sound power level

(L

WA

) ;

A-weighted value of

89.5 dB; (Includes

K

WA

= 2.5 dB);

according to ISO

10821- C.6.2 -ISO

3744 GR2 at 2,200

sti/min.

- Equivalent

continuous emission

sound pressure

level (L

pA

) at the

workstation :

A-weighted value of

78.0 dB; (Includes

K

pA

= 2.5 dB);

according to ISO

10821- C.6.2 -ISO

11204 GR2 at 2,200

sti/min.

Loading...

Loading...