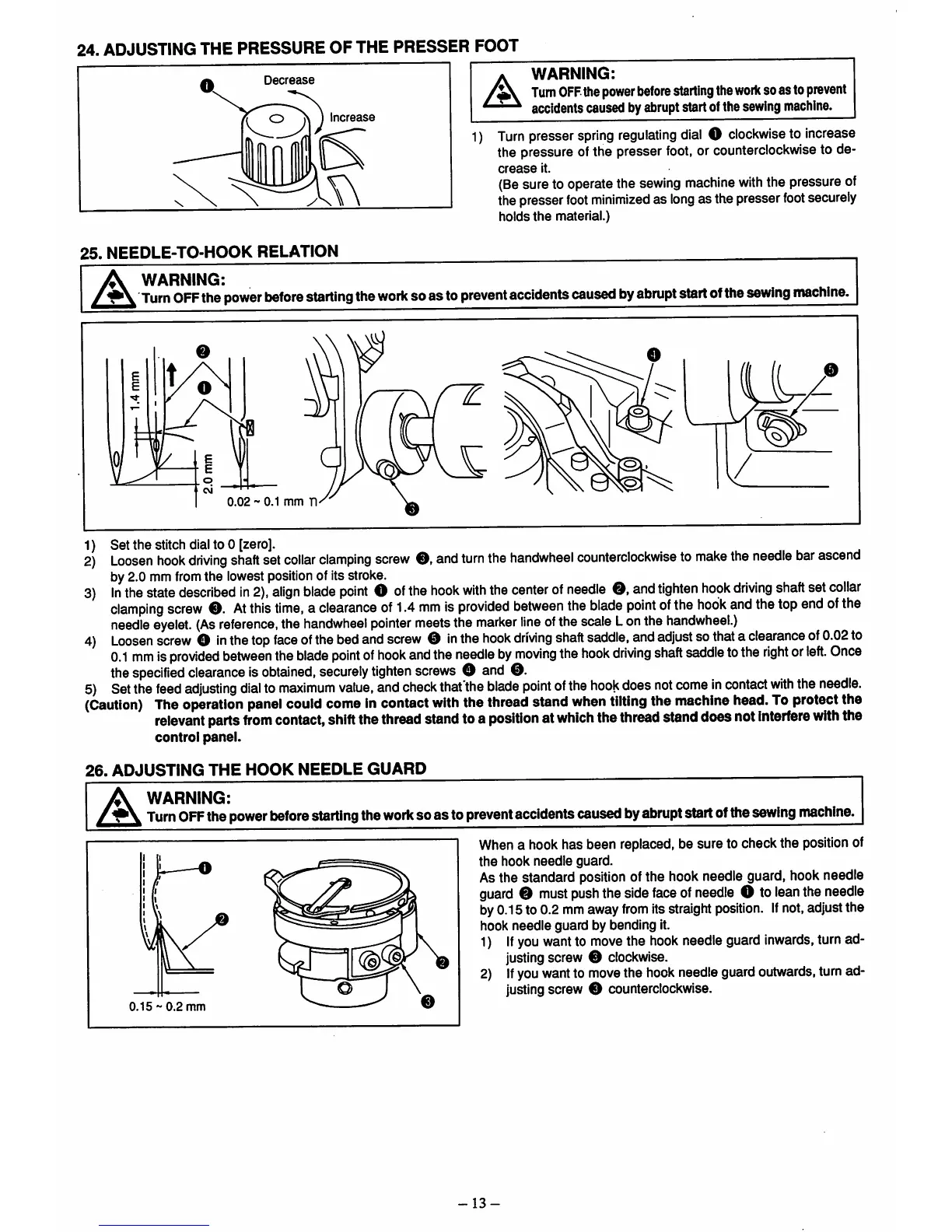

24. ADJUSTING THE PRESSURE OF THE PRESSER FOOT

Increase

A

WARNING:

Turn

OFF

the

power

before

starting

the

work

soasto

prevent

accidents

causedby

abrupt

startofthe

sewing

machine.

1)

Turn

presser

spring

regulating

dial

O

clockwise

to

increase

the pressure ofthe presser

foot,

or

counterclockwise

to de

crease

it.

(Be

sureto

operate

the

sewing

machine

with

the

pressure

of

thepresser

foot

minimized

as

long

as thepresser

foot

securely

holds

the

material.)

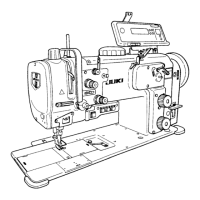

25.

NEEDLE-TO-HOOK

RELATION

4)

5)

WARNING:

Turn

OFF

the

power

before

starting

the

work

soasto

prevent

accidents

caused

by

abrupt

start

of

the

sewing

nwchine.

t

e

o

VAt

V

0.02

~

0.1

mm

n

Set

the

stitch dial to 0 [zero].

Loosen

hook

driving

shaft

set

collar

clamping

screw

O,

and

turn

the

handwheel

counterclockwise

to

make

the

needle

bar

ascend

by2.0 mm

from

the lowestposition of its stroke.

In

the

state

described

in

2),

align

blade

point

O

of

the

hook

with

the

center

of

needle

O,

and

tighten

hook

driving

shaft

set

collar

clamping

screw

©.

At

this

time,

a

clearance

of

1.4

mm

is

provided

between

the

blade

point

of

the

hook

and

the

top

end

of

the

needle

eyelet.

(As

reference,

the

handwheel

pointer

meets

the

marker

line

of

the

scale

L

on

the

handwheel.)

Loosen

screw

O

in

the

top

face

of

the

bed

and

screw

©

in

the

hook

driving

shaft

saddle,

and

adjust

so

that

a

clearance

of

0.02

to

0.1

mm

is

provided

between

the

blade

point

of

hook

and

the

needle

by

moving

the

hook

driving

shaft

saddle

to

the

right

or

left.

Once

the

specified

clearance

Is

obtained,

securely

tighten

screws

O

and

©.

sj!

Set

the

feed

adjusting

dial

to

maximum

value,

and

check

that

the

blade

point

of

the

hook

does

not

come

in

contact

with

the

needle.

(Caution)

Tlie

operation

panel

could

come

in

contact

witfi

the

thread

stand

when

tilting

the

machine

head.

To

protect

the

relevant

parts

from

contact,

shift

the

thread

stand

toa

position

at

which

the

thread

stand

does

not

Interfere

with

the

control

panel.

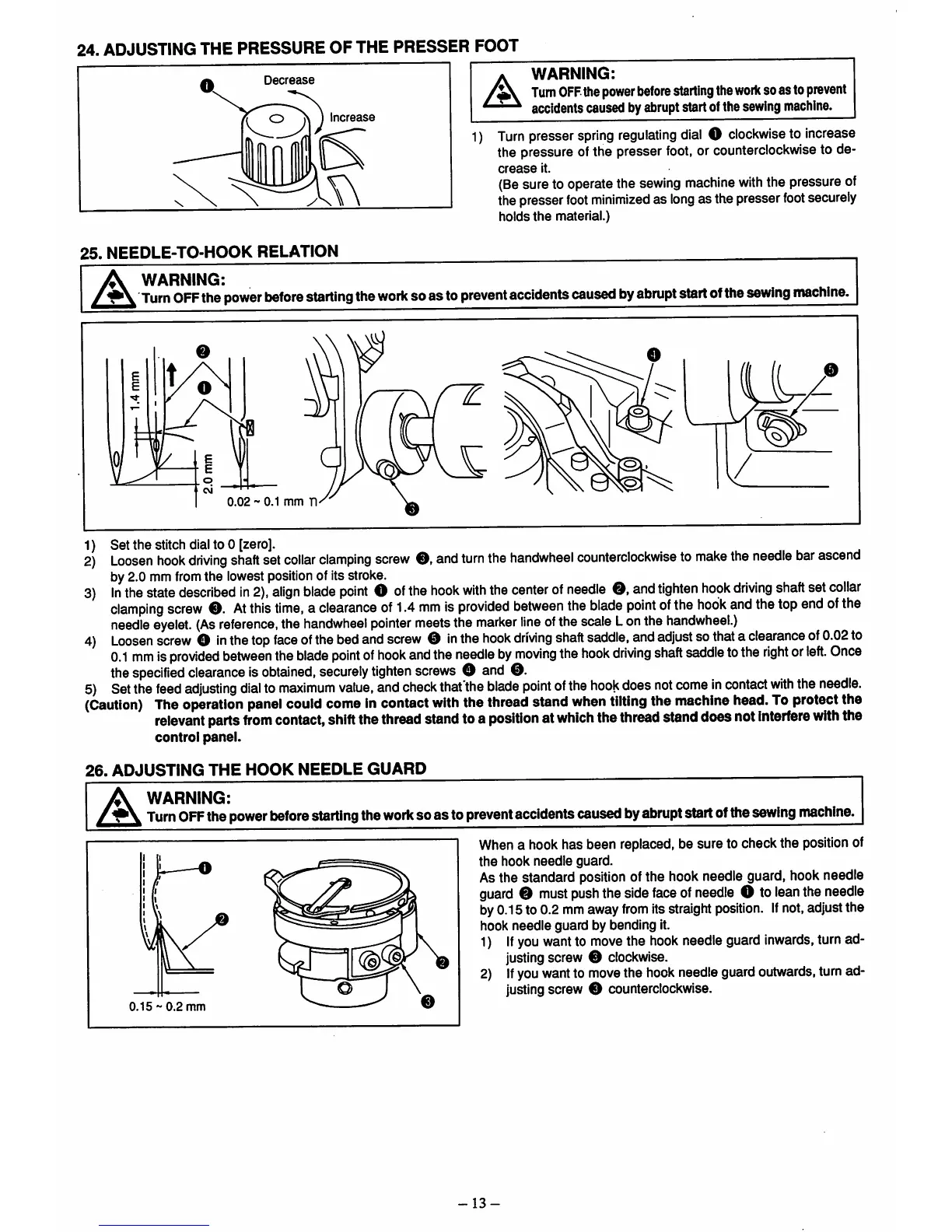

26.

ADJUSTING

THE

HOOK

NEEDLE

GUARD

A

WARNING:

Turn

OFF

the

power

before

starting

the

work

soasto

prevent

accidents

caused

by

abrupt

startofthe

sewing

machine.

When

a hookhas been replaced, be sure tocheckthe

position

of

the

hook

needle

guard.

Asthe standard

position

ofthe hookneedle guard, hookneedle

guard

©

must

push

theside

face

of

needle

O to

lean

the

needle

by0.15to 0.2

mm

away

from

itsstraight

position.

If

not,adjustthe

hook needle guard by bending it.

1)

If

you

want

to

move

the

hook

needle

guard

inwards,

turn

ad

justing

screw ©

clockwise.

2)

If

you

wantto

move

the

hook

needleguardoutwards, turnad

justing

screw © counterclockwise.

0.15

~

0.2

mm

-13-

Loading...

Loading...