– 29 –

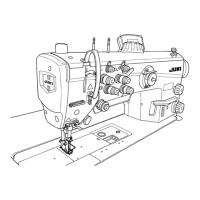

Adjustment procedures

Results of Improper adjustment

o

Except for LU-2828-6, 2828-7

1. Set the stitch dial to “6”.

2. Loosen two setscrews

❶

of the feed adjusting eccentric pin.

3. Turn feed adjusting eccentric pin

❷

to adjust the stitch length.

o

Direction A

→

Reverse feed length is increased.

o

Direction B

→

Normal feed length is increased.

4. After the adjustment, securely tighten two setscrews

❶

of the

feed adjusting eccentric pin.

(Standard) When the direction of notched part of the feed

adjusting eccentric pin

❷

is set to just above as

shown in the illustration, the feed amounts of nor-

mal and reverse feeds are nearly the same.

o

In case of LU-2828-6, 2828-7

1. Set the stitch dial to “6”.

2. Loosen three setscrews

❸

from rear side of the machine arm,

and remove the cylinder unit

❹

.

3. Loosen setscrew

❺

of the feed adjusting base support shaft.

4. Turn the feed adjusting base support shaft

❻

to adjust the

stitch length.

o

Direction C

→

Reverse feed pitch is increased.

o

Direction D

→

Normal feed pitch is increased.

5. After the adjustment, securely tighten setscrew

❺

of the feed

adjusting base support shaft.

6. Return the cylinder unit

❹

to its original position, and securely

tighten three setscrews

❸

.

(Caution) When assembling the motor cover, be careful not to

pinch the code and the tube.

* When performing "2.-(21) 2P feed adjustment", perform forward/

reverse stitch length adjustment of standard feed after performing

forward/reverse stitch length adjustment of 2P feed.

o

Respective stitch lengths of

normal and reverse feeds do not

match.

Loading...

Loading...