– 31 –

Adjustment procedures

Results of Improper adjustment

o

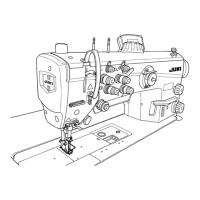

In case of LU-2810-6, 2810-7, 2860-6, 2860-7, 2828-6, 2828-7,

2818-7, 2868-7

1. Set the stitch dial to the maximum.

2. Loosen clamping screw

❶

of the reverse feed connecting arm.

3. Adjust so that a play of top end

A

of the reverse feed control

lever

❷

is 1 ± 0.5 mm (LU-2828-6, 2828-7 : 7.5 to 8 mm). Then

tighten clamping screw

❶

of the reverse feed connecting arm.

o

In case of LU-2810, 2860

1. Set the stitch dial to the maximum.

2. Loosen clamping screw

❸

of the feed adjusting pin support

arm.

3. Turn the reverse feed lever shaft

❺

to adjust so that a clear-

ance between the reverse feed lever plate

❹

and the stopper

part

B

of machine arm is 0.1 to 0.5 mm. Then tighten clamping

screw

❸

of the feed adjusting pin support arm.

(Caution) Check that the reverse feed control lever

❷

does not

interfere with the machine bed or machine arm when

the stitch dial is set to the maximum.

When the position of the reverse

feed control lever

❷

is low :

o

Reverse feed lever plate

❹

interferes with the machine

arm and the stitch length of the

reverse feed stitching will be

decreased.

When the position of the reverse

feed control lever

❷

is high :

o

Reverse feed lever plate

❹

in-

terferes with the stopper part

B

of machine arm, or reverse feed

control lever

❷

interferes with

machine arm, and stitch length

of the normal feed stitching will

be decreased.

Loading...

Loading...