ENGLISH

– 23 –

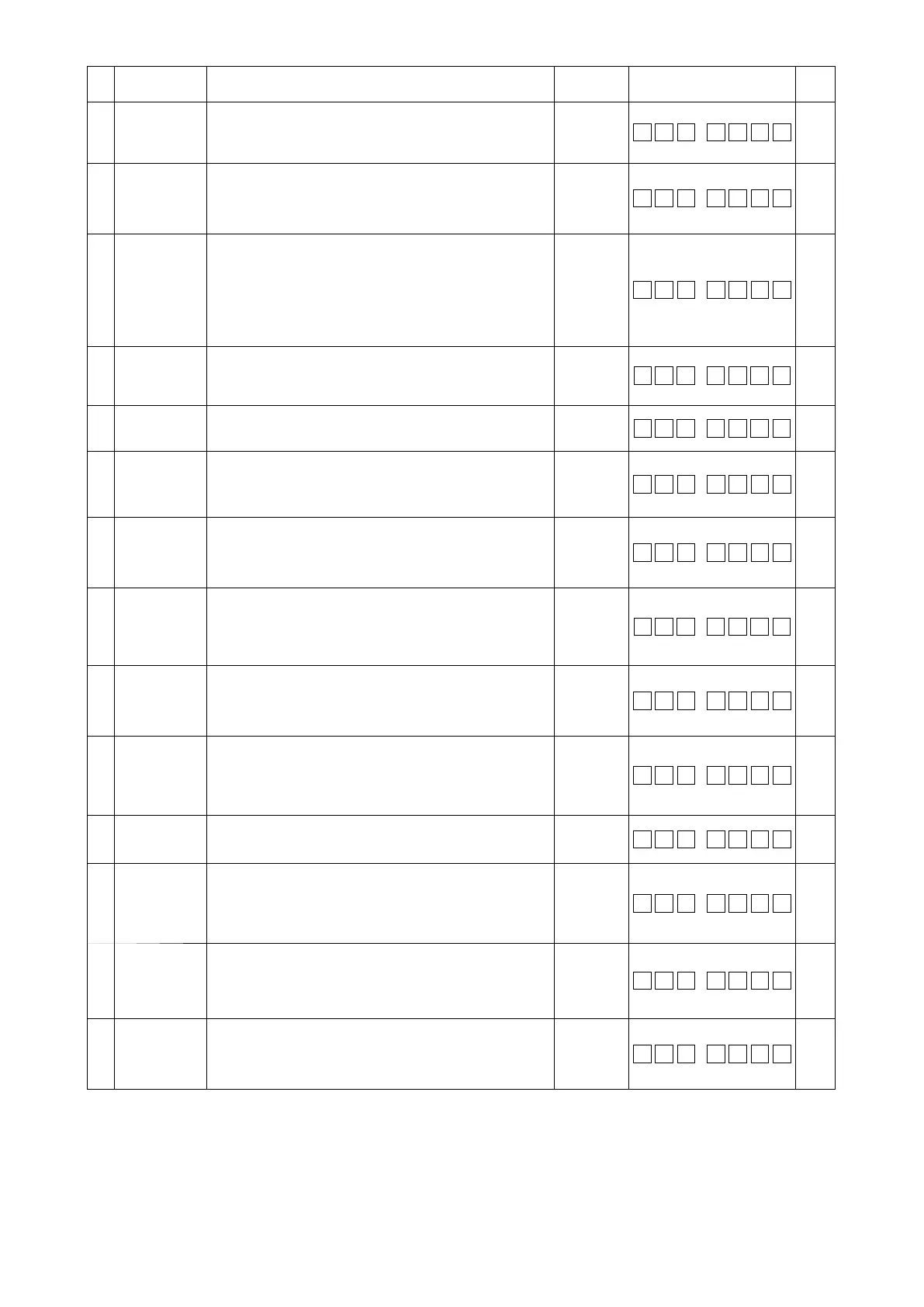

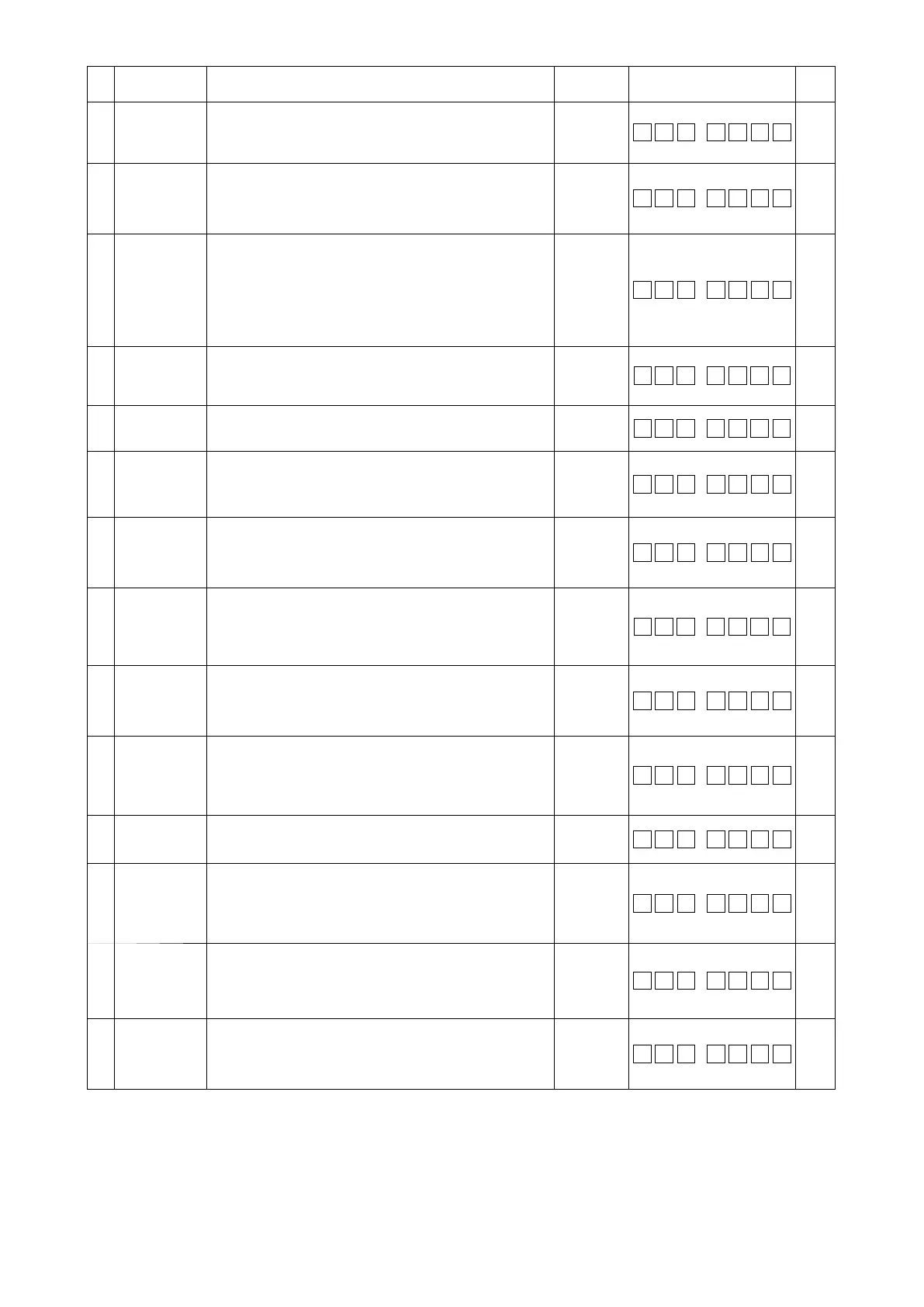

No

Item Description Setting range Indication of function setting

Ref.

page

*

91

Function of prohibit-

ing compensation

operation after turning

handwheel by hand

Function of compensating stitching when turning handwheel by hand

at the time of completion of constant-dimension stitching

0 : Function of compensating stitching is ef

fective.

1 : Function of compensating stitching is prohibited.

0/1

9 1 1

92

Function of

reducing speed of

reverse feed stitch-

ing at the start of

sewing

Function to reduce speed at the time of completion of reverse feed

stitching at the start of sewing.

0 : Speed is not reduced.

1 :

Speed is reduced.

0/1

9 2 0

34

93

Function added to

needle up/down

compensating

switch

Operation of needle up/down compensating switch is changed after

turning ON the power or thread trimming.

0 : Normal (needle up/down compensating stitching only)

1 :

One stitch compensating stitching is performed only when aforemen-

tioned changeover is made. (Upper stop

/

upper stop)

2 : Needle-down function operates after thread trimming.

3 : Function of needle-down with operation of 2 plus presser lower-

ing operation and needle-up with thread trimming operation is

added.

0 to 3

9 3 0

35

95 Head selection

Head to be connected is selected.

(In case of the head with resistor pack, the head is automatically

selected when resistor pack is connected.)

9 5 L U. 2 v

96

Max. number of

rotation setting

Max. number of rotation of the sewing machine head can be set

* Setting differs in accordance with the head (resistor pack)

to be connected.

150 to MAX

(rpm)

9 6 3 5 0 0

35

100

2-pitch output during

reverse feed stitch-

ing at sewing start

or end

Existence/non-existence of 2-pitch output during controlling reverse

feed stitching at sewing start or end is set.

0 : Invalid

1 : Valid

0/1

1

0 0 0

35

101

Inversion of

2-pitch output

during outputting

alternate vertical

amount

Existence/non-existence of inversion output of 2-pitch output syn-

chronizing with alternate vertical output is set.

0 : Invalid

1 : Valid

0/1

1

0 1 0

36

102

2-pitch initial

output selection

Whether 2-pitch output at the time of turning ON the power is to be

"ON" or "OFF" can be set.

0 : Output ON

1 :

Output OFF

2 : It is returned to the state immediately before turning OFF the

power.

0/1/2

1

0 2 1

36

103 Number of stitches

of automatic

release of alternate

vertical output set-

ting

Release of alternate vertical output is automatically performed by

number of stitches.

0 : Automatic release is invalid.

1 to 30 stitches

0 to 30

(Stitch)

1

0 3 0

36

104

Selection of up-position

of automatic presser

lifting at the time of

reverse revolution to

lift needle of thread

trimming

Automatic presser lifting timing at the time of reverse revolution to lift

needle of thread trimming is selected to up-position.

0 : Invalid

1 : Valid

0/1

1

0 4 0

36

105

Needle cooler

output OFF delay

time

Delay time from the stop to output OFF is set with the needle cooler

output function.

0 to 2000

(100ms)

1

0 5 5 0 0

36

107 Selection of

alternate verti-

cal output after

thread trimming

This function forcibly outputs ON/OFF of the alternate vertical output

after thread trimming.

0 : Output state maintained

1 : OFF output

2 : ON output

0/1/2

1

0 7 0

36

109

Selection of

needle thread

clamp switch

function

Valid/invalid of pattern sewing function is set.

Selection of needle thread clamp switch function (LU-2220 head)

0 : Needle thread clamp motion is invalid.

1 : ON/OFF with the motion valid switch

2 : Forcibly valid

0/1/2

1

0 9 0

36

112

Setting of brake

starting angle at

the time of thread

trimming up-

position stop

This function sets the brake starting angle at the time of thread trim-

ming up-position stop. (0 : Up-detection start)

0 to 10

(1˚)

1

1 2 0

36

* Do not change the set values with asterisk (*) mark as they are functions for maintenance. If the standard set value set at the

time of delivery is changed, it is in danger of causing the machine to be broken or the performance to be deteriorated.

If it is necessary to change the set value, please purchase the Engineer’s Manual and follow the instructions.

(Descriptions of setting in this list are the standard values at the time of delivery.)

However, contents of function setting are subject to change for improvement of function and performance without notice.

Loading...

Loading...