– 20 –

0 to 0.2

Needle

Blade point

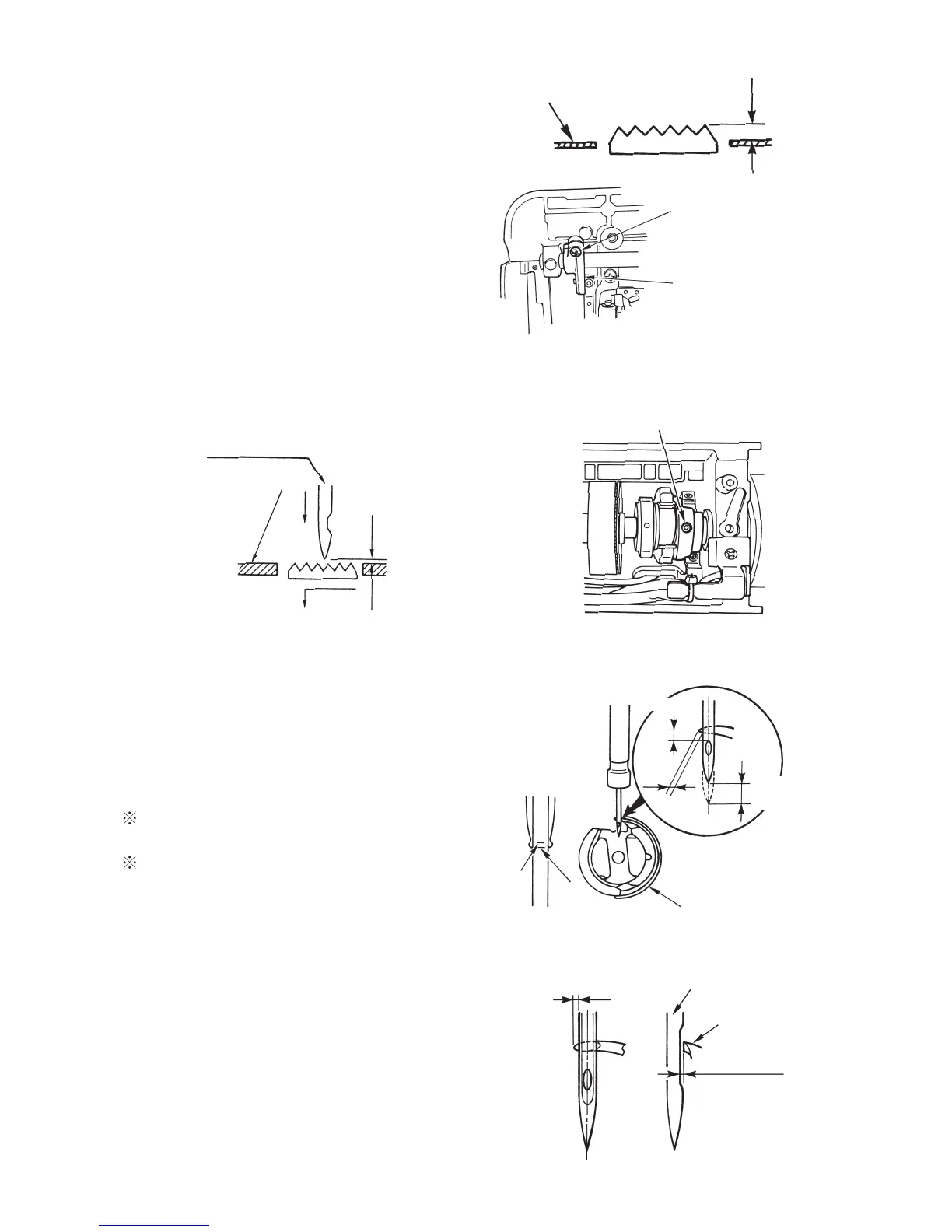

4. Height of feed dog

™ Set stitch dial to 2 and bring feed dog to its highest

position.

™ See the height on the rear side of feed dog.

™ Bottom of tooth of feed dog should be aligned with

top surface of throat plate.

(Figure on the right side : protruding amount from

top surface of throat plate is 1.2 ± 0.1 mm.)

™ Perform adjustment with 1 vertical feed shaft arm.

5. Feed timing

™ Set stitch dial to P=2.

™ Lower feed dog in the normal feed operation and align it with top surface of throat plate.

™ At this time, clearance provided between needle top and top surface of throat plate is 0 ± 0.2 mm.

™ Perform adjustment with feed cam setscrew.

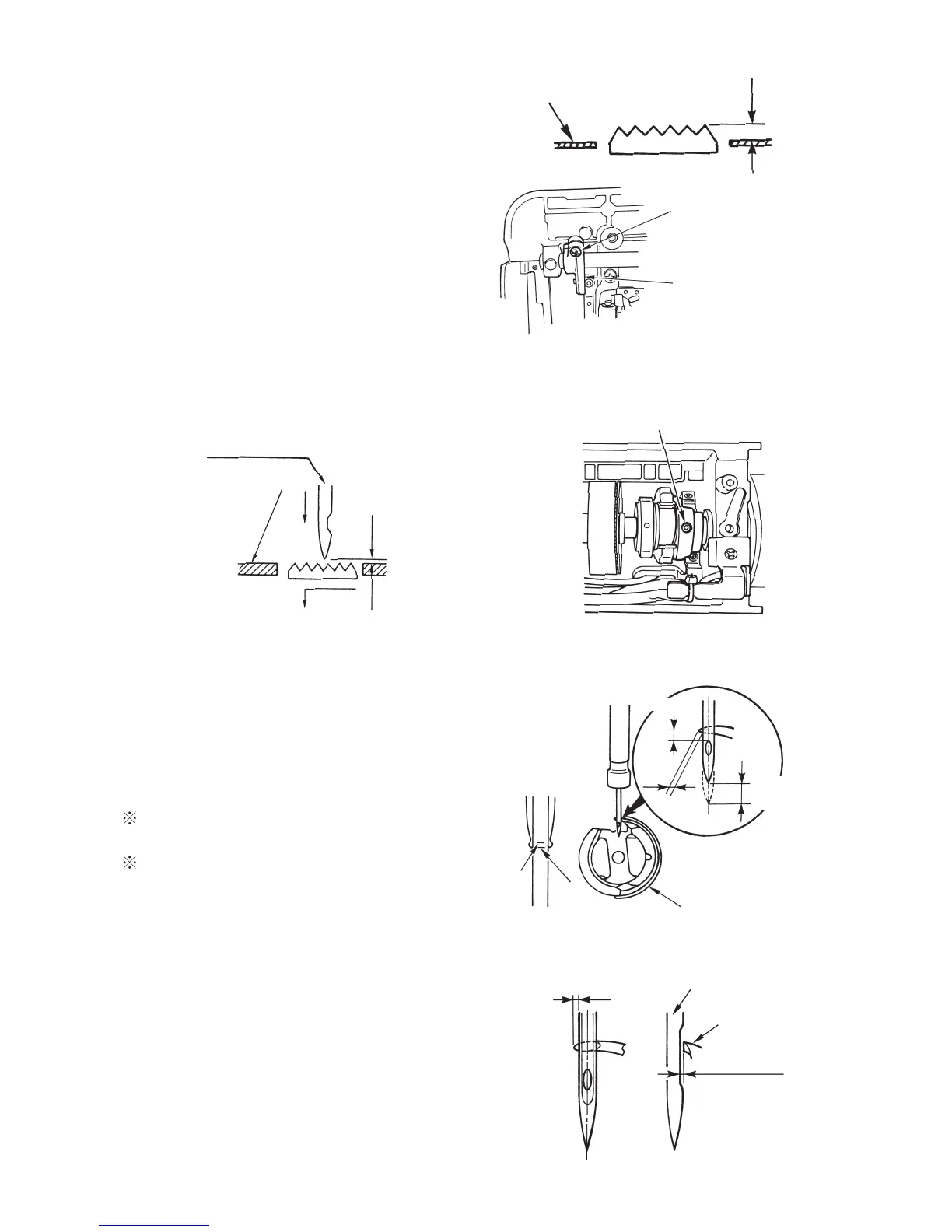

6. Needle-to-hook timing

™ Loosen three setscrews in hook.

™ Adjust blade point of hook and left edge of needle

to 0 to 0.2 mm when needle bar lifts by 2.17 mm

from its lower dead point.

™ Check clearance between needle and hook, and

tighten setscrews.

Remove bobbin case positioning finger to improve

the work.

Standard of position of 2 mm from lower dead point

of needle bar is that of engraved lines 1 to 2 on

needle bar.

(1 Lower dead point, 2 Position of lifting 2 mm)

7. Clearance between needle and hook

™ Loosen three setscrews in hook.

™ Adjust blade point of hook to position of 0.2 mm

from left edge of needle.

™ Adjust clearance between blade point of hook and

needle to 0.02 to 0.07 mm.

™ Temporarily tighten setscrews, check timing, and

securely tighten setscrews.

Top surface of throat plate

1.2 ± 0.1 mm

Feed cam setscrew

Needle : TL-98Q (HA x 1 #14)

TL-98QE (HL x 5 #14)

Top surface of throat plate

0±0.2 mm

Hook

2

1

1 Vertical feed shaft arm

2 Shaft arm setscrew

0 to 0.2

1.33 mm

0.02 to 0.07 mm

Lifting amount

2.17 mm

Loading...

Loading...