2-20

2.8.1 Tape pattern check

(1) Play back the compatibility adjustment tape.

(2) While triggering the MAIN CN107-10PIN (HID1), ob-

serve the waveform of CN107-26PIN (ENV_OUT).

(3) Confirm that the waveform is free from remarkable

level-down, and entirely parallel and straight.

Moreover, perform the following adjustment as re-

quired.

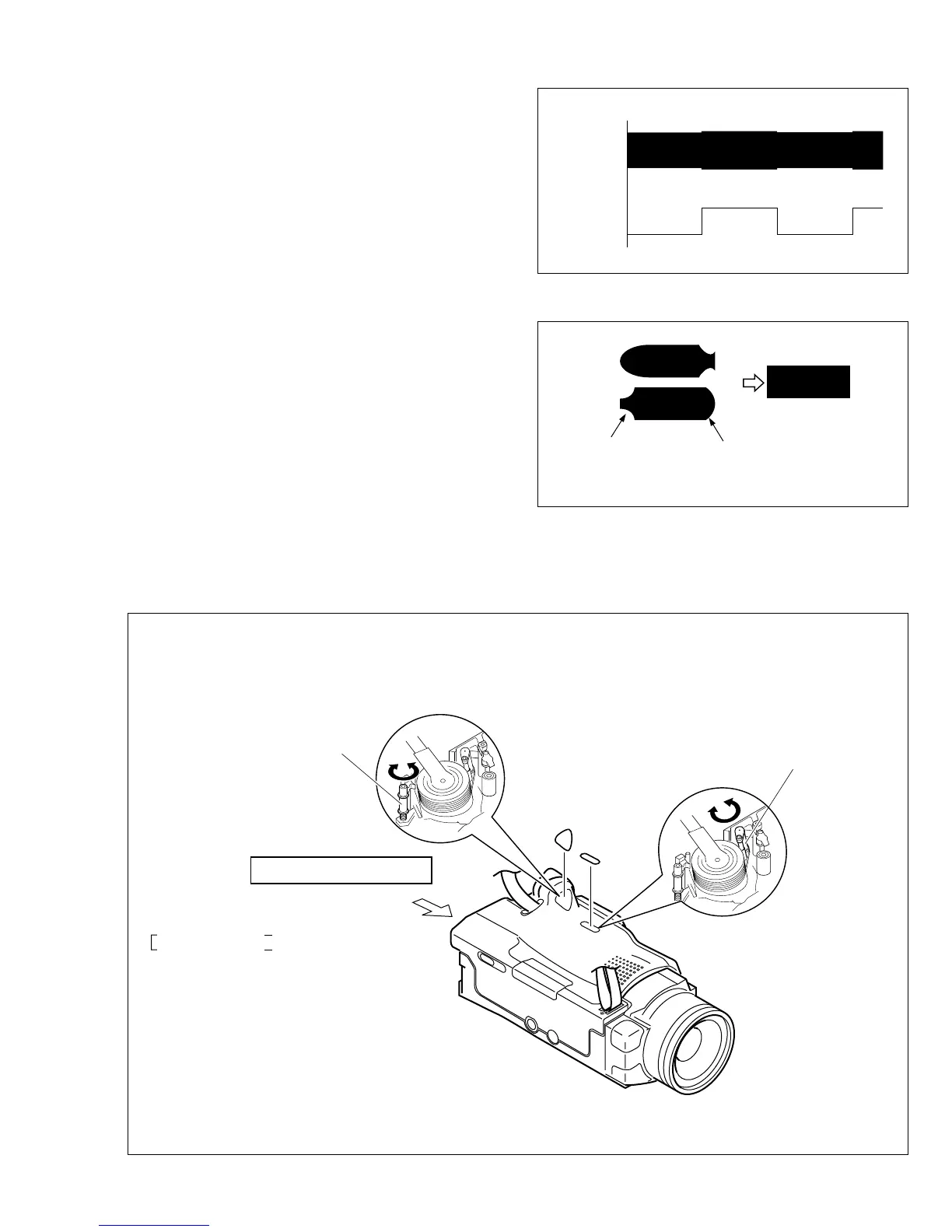

(4) In case any level-down is observed on the left hand

side, straighten the level by turning the guide roller of

the pole base assembly (supply).

In case any level-down is observed on the right hand

side, however, straighten the level by turning the guide

roller of the pole base assembly (Take-up).

(5) After adjustment, try the unloading motion once, and

confirm that the waveform is flat (straight) when the

tape has been played back again.

Moreover, perform readjustment as required.

(6) When the recording has been played back again, play

back the self-recording to confirm that the waveform

is flat.

Fig. 2-8-3

Fig. 2-8-4

Fig. 2-8-5

CN107

(ENV_OUT)

CN107

(HID1)

Flatten the waveform.

Misalignment of guide roller

height on the take-up side

Misalignment of guide

roller height on the

supply side

COVER

(Cassette)

COVER

(Cassette

rear)

Refer to page 2-19.

MAIN CN107

26PIN (ENV_OUT)

10PIN (HID1)

JIG CONNECTOR CABLE

JIG CONN. BOARD

JIG CONN-26PIN (ENV_OUT)

JIG CONN-10PIN (HID1)

GUIDE ROLLER

(SUP) ASSY

NOTE:

The two covers serve as the covers for the

service adjustment access holes.

GUIDE ROLLER (TU) ASSY

Note:

When an adjustment is performed with the lower case cover

attached, first slide the two covers (cassette and cassette

rear) open and then perform the compatibility adjustment.

Be sure not to damage the covers when sliding them open

to make an adjustment because they must be re-positioned

after completing the adjustment.

Loading...

Loading...