26

GB

1. Installation and Connection

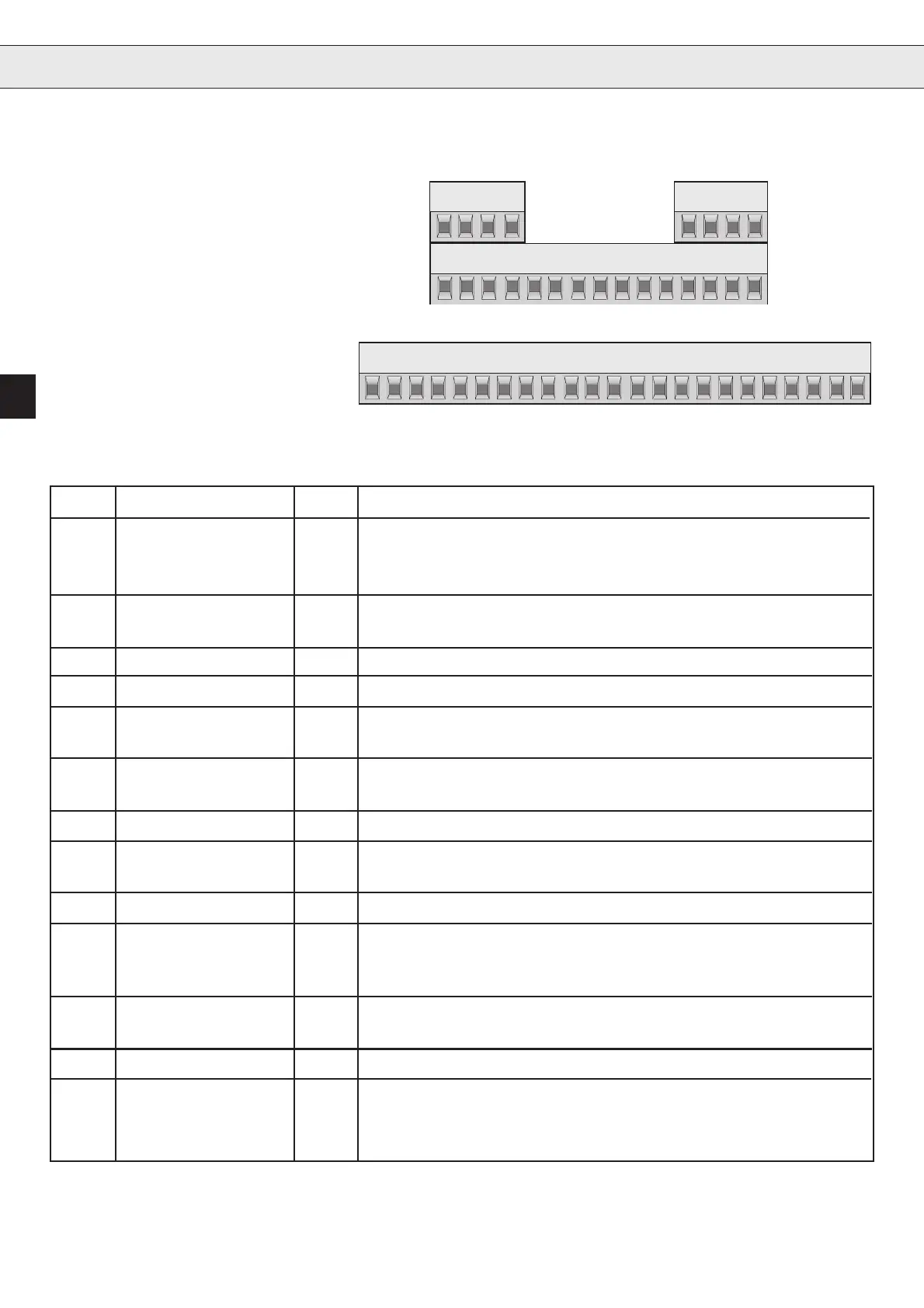

123456789101112

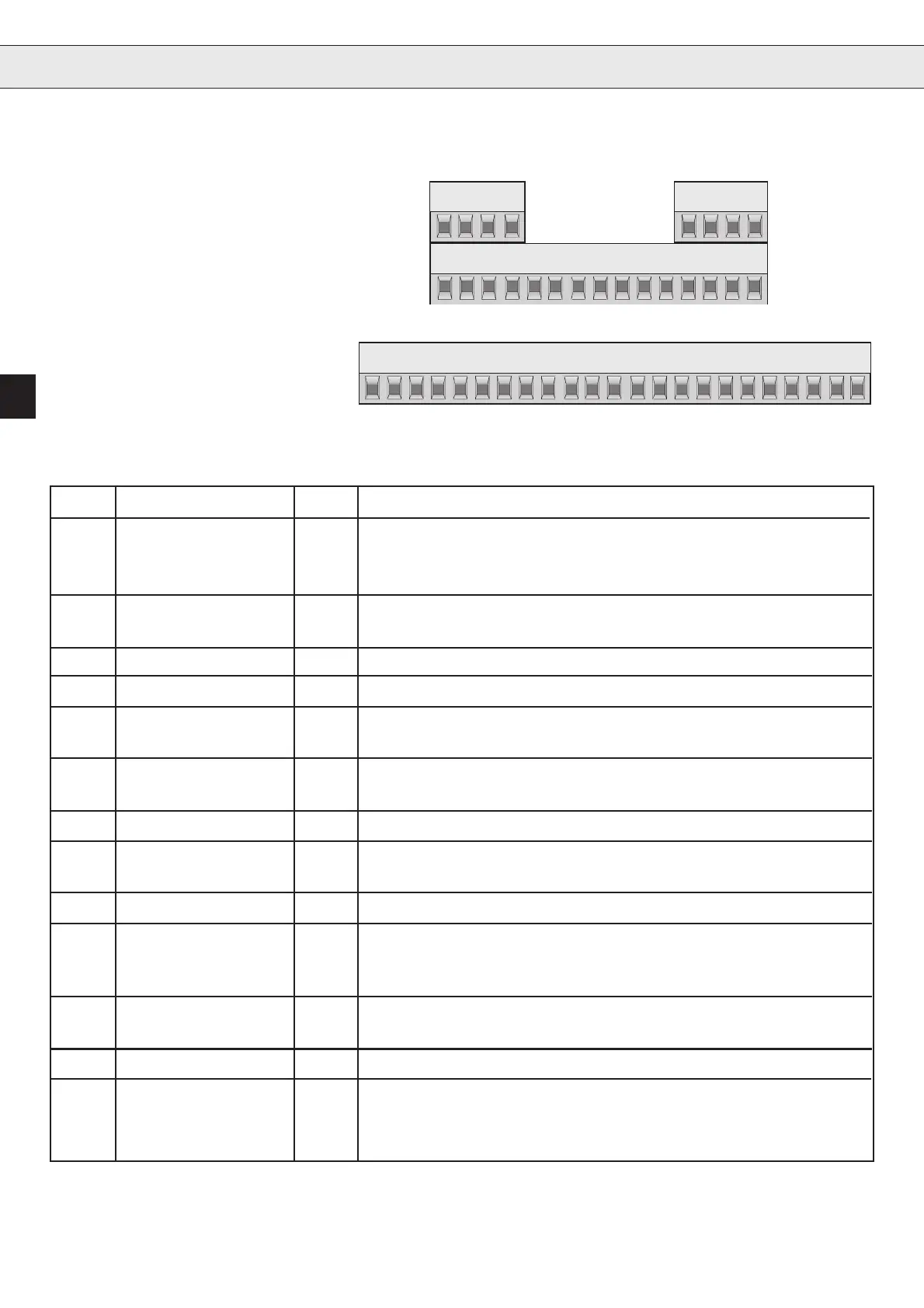

13 14 15 16 17 18 19 20 21 22 23

20 22 23

1234

21

16 17 1856789101112131415 19

1.1.1Assignment of

Terminal Strip X1

1.1. Control circuit

Version C

PIN Function Name Description

X1.1 NO contact RLA Relay output

X1.2 Opening contact RLB Function see parameter CP.22

X1.3 Switching contact RLC ( factory setting: fault indication)

X1.4 Fixed frequency 1 I1 X1.4 + X1.5 = fixed frequency 3

X1.5 Fixed frequency 2 I2 no input = analog set value

X1.6 DC-braking I3 activates the dc-braking

X1.7 Energy saving funct. I4 Output voltage is reduced to 70%

X1.8 REF+ REF+ Difference voltage; Voltage difference is added to/

X1.9 REF- REF- subtracted from inputREF (X1.17)

X1.10 Forward F Preset rotation; forward has priority

X1.11 Reverse R

X1.12 Frequency depend. OUT1 Transistor output switches at switch f

real

= f

set

X1.13 Digital Mass 0V Potential for digital in-/outputs

X1.14 15V +15V voltage supply for digital in-/outputs (max.100mA)

X1.15 Analog output AOUT Analog output of the real frequency 0...10VDC = 0...100Hz

X1.16 +10V CRF Supply voltage for set value potentiometer (max. 4 mA)

X1.17 Set value input REF Factory setting 0...10V (0...20 and 4...20mA adjustable with CP.24)

X1.18 Common COM Mass for analog in- and outputs

X1.19 Control release ST Power modules are triggered; if opening in case of error

Reset; if opening during operation, the motor costs.

X1.20 Reset RST Hardware reset; only possible when an error occurs

X1.21 NO contact FLA Relay output; switches,when level

X1.22 Opening contact FLB from parameter CP.23 is reached

X1.23 Switching contact FLC (frequency dependent switch)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...