B-10 Command Reference

Error 508 Will occur when a :CAL:PROT:SENS command generates an invalid

measurement gain calibration constant.

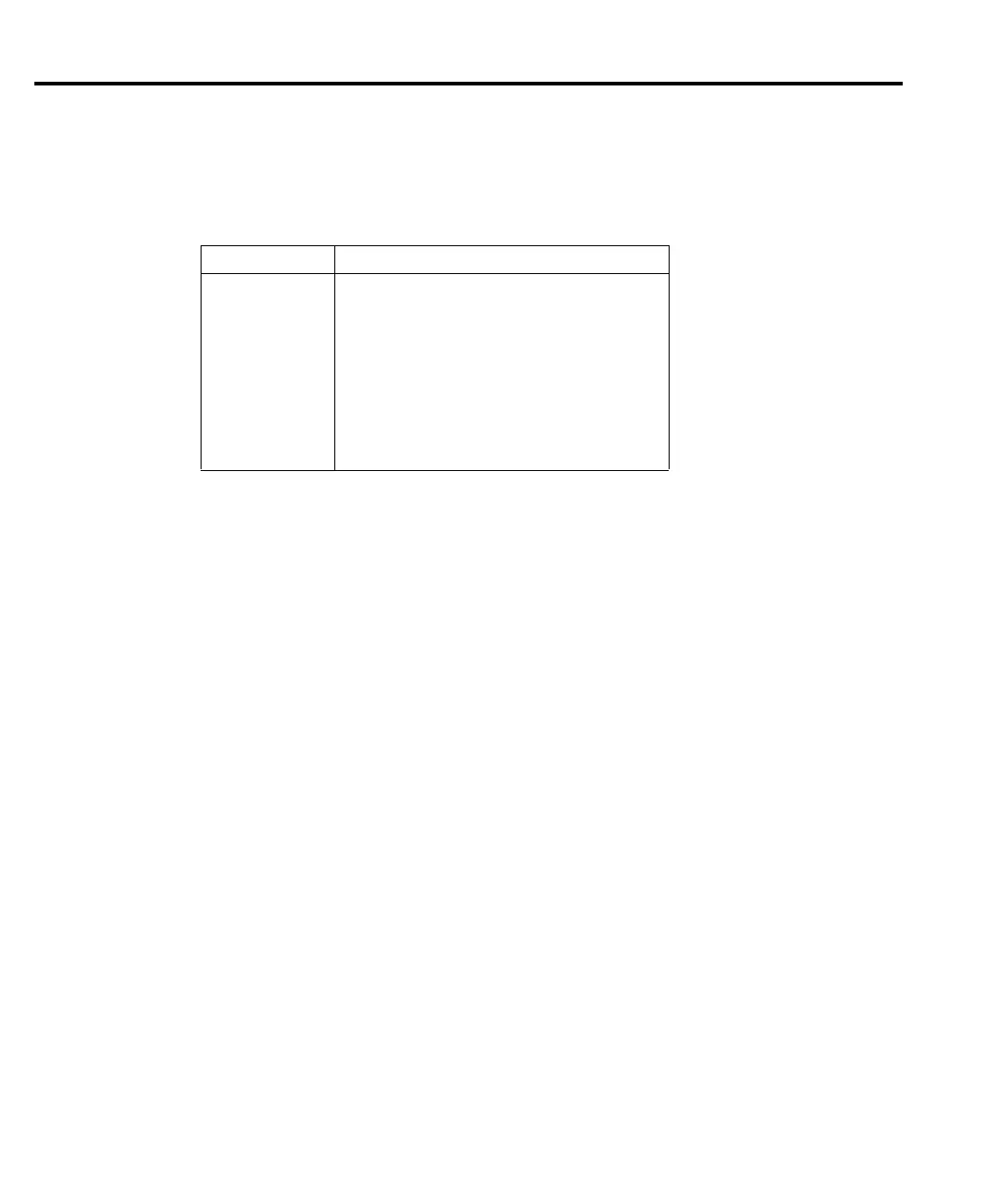

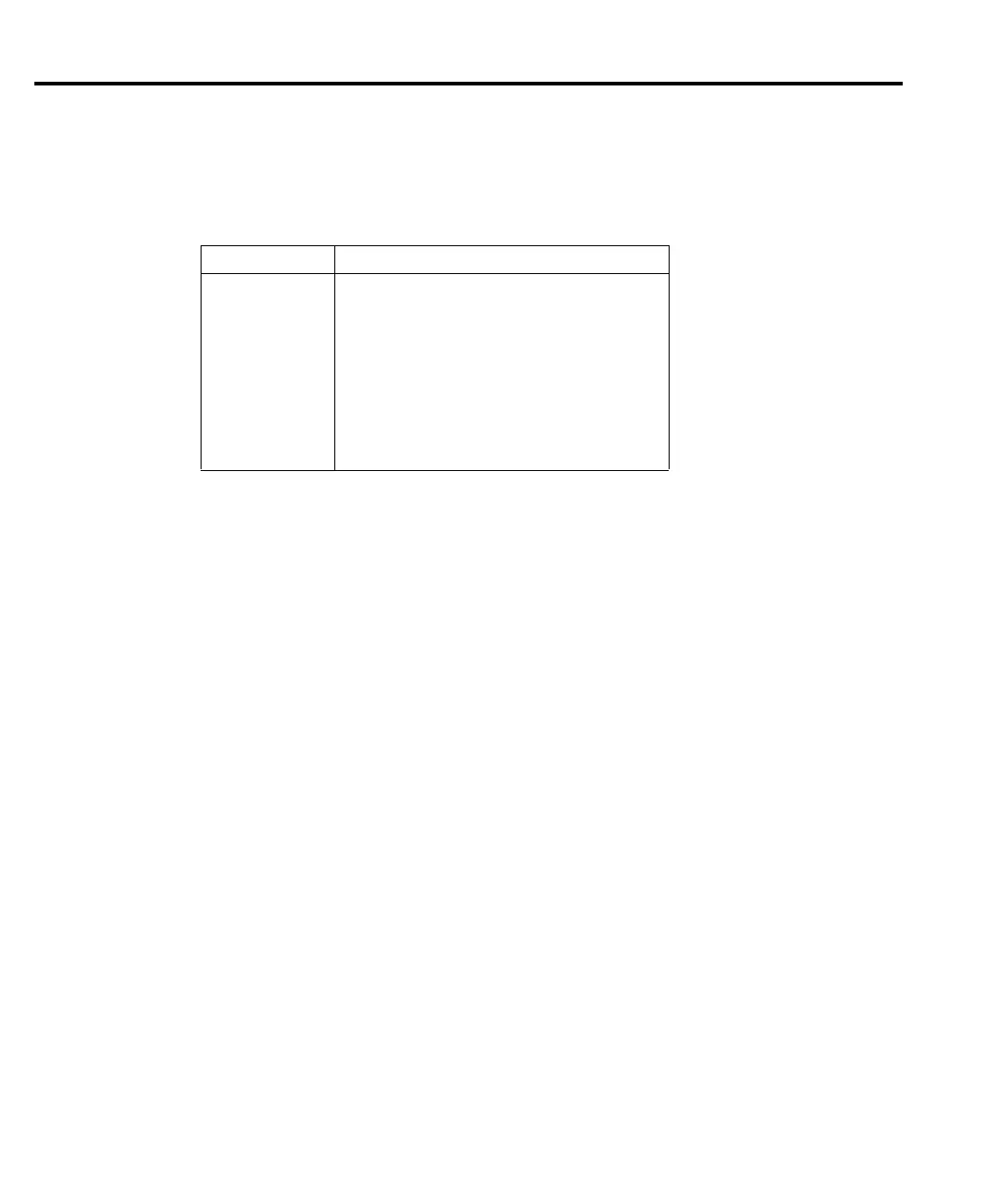

Table B-4

Calibration errors

Error number Error message

+500 “Date of calibration not set”

+501 “Next date of calibration not set”

+502 “Calibration data invalid”

+503 “DAC calibration overflow”

+504 “DAC calibration underflow”

+505 “Source offset data invalid”

+506 “Source gain data invalid”

+507 “Measurement offset data invalid”

+508 “Measurement gain data invalid”

Status byte EAV (Error Available) bit

Whenever an error is available in the error queue, the EAV (Error Available) bit (bit 2) of the

status byte will be set. Use the *STB? query to obtain the status byte, then test bit 2 to see if it

is set. If the EAV bit is set, an error has occurred, and you can use the appropriate error query to

read the error and at the same time clear the EAV bit in the status byte.

Generating an SRQ on error

To program the instrument to generate an IEEE-488 bus SRQ (Service Request) when an error

occurs, send the *SRE 4 command. This command will enable SRQ when the EAV bit is set.

You can then read the status byte and error queue as outlined above to check for errors and to

determine the exact nature of the error.

Loading...

Loading...