M56O720A

careful not to allow dust or

dirt to enter the fuel system.

Contaminations in the fuel

system could damage the fuel

•

•

IMPORTANT

-

ing the items above.

a fuel leak. Fuel leaking on a hot

•

•

WARNING

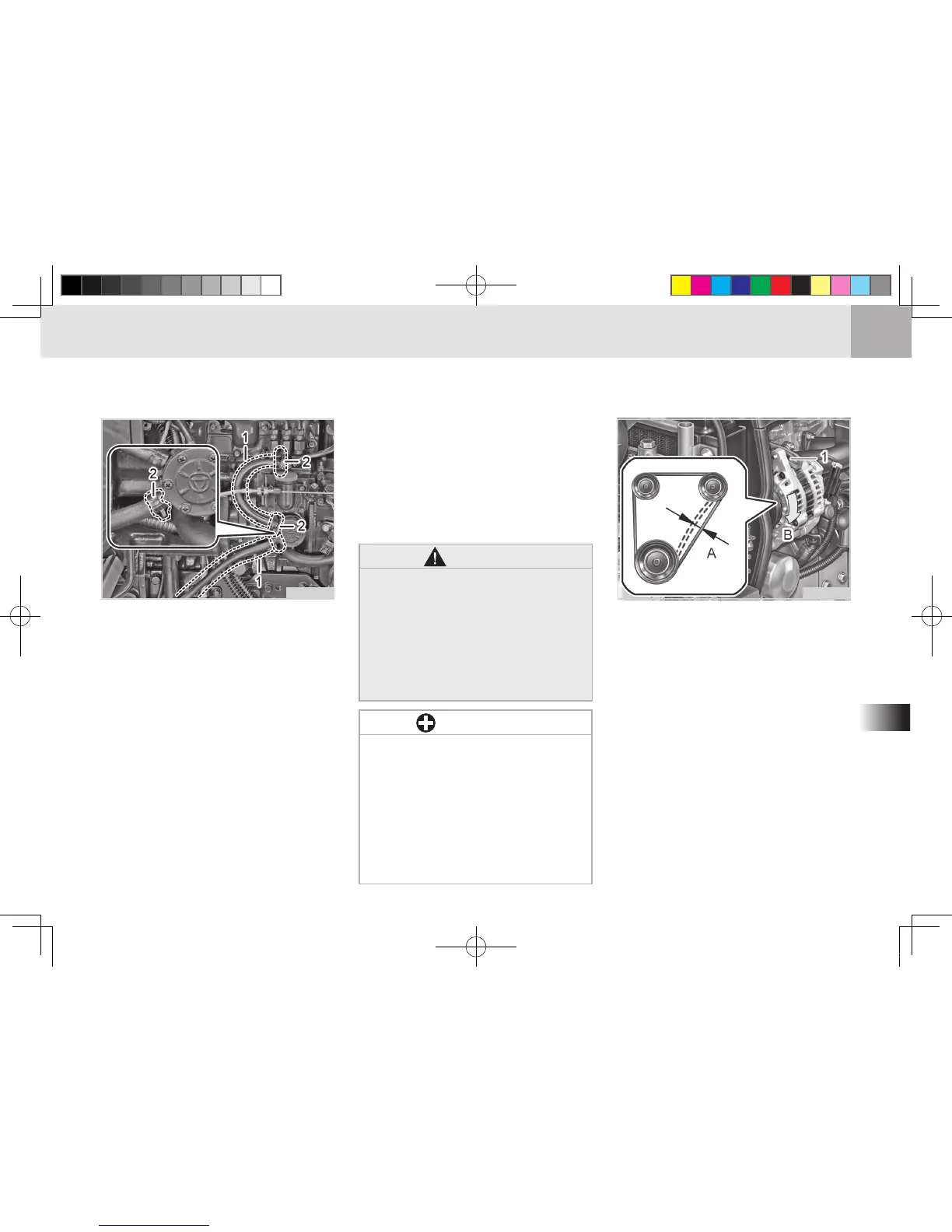

(1) Fuel Pipe (2) Tightening Band

Although checking the fuel pipe con-

nection is recommended every 100

service hours, it should be done ev-

ery 6 months if operation does not

exceed 100 hours in 6 months.

1. If the hose clamps are loose, apply

a slight coat of lubricant onto the

threads and securely tighten it.

2. The fuel pipe is made of rubber

and ages regardless of period of

service. Change the fuel pipe to-

gether with the hose clamps every

two years and securely tighten.

3. If the fuel pipes and hose clamps

are found damaged or deterio-

rated earlier than two years, then

change them immediately.

4. Af t e r t h e f u e l p i p e a n d h o s e

clamps have been changed, bleed

the fuel system.

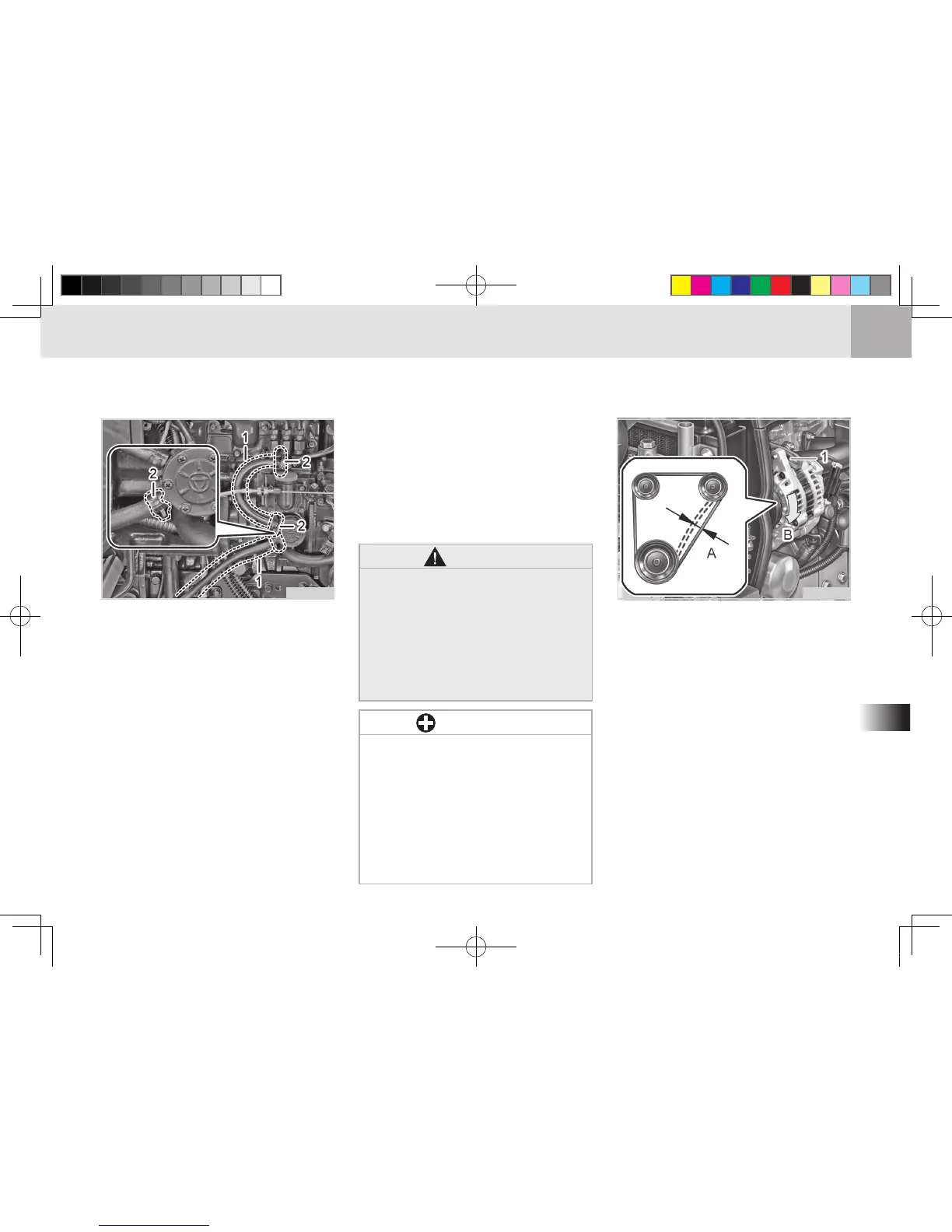

In order to extend the fan belt’s life-

time, the tension of the belt should

be correctly adjusted if it slips. The

belt tension should be inspected

regularly according to the following

procedure:

1. Stop the engine and apply the

parking brake.

2. Open the hood and remove the

left side cover.

3. Remove the mounting bolts and

adjusting bolt of the alternator.

196OA33C

(1) Adjusting Bolt

(A) Adjusting Belt Tension (B) Pull

ADJUSTING FAN BELT TEN-

Loading...

Loading...