TP-6137 5/03 35Section 6 Cooling System

6.5 Anticorrosion Zinc Anode

The generator set includes an anticorrosion zinc anode

(plug) to prevent electrolytic corrosion by seawater.

Check and replace the anticorrosion zinc anode at

intervals recommended in the service schedule.

Depending upon operating conditions and seawater

properties, the anticorrosion zinc anode may require

more frequent replacement. See Figure 6-7 for the

location and use the following procedure.

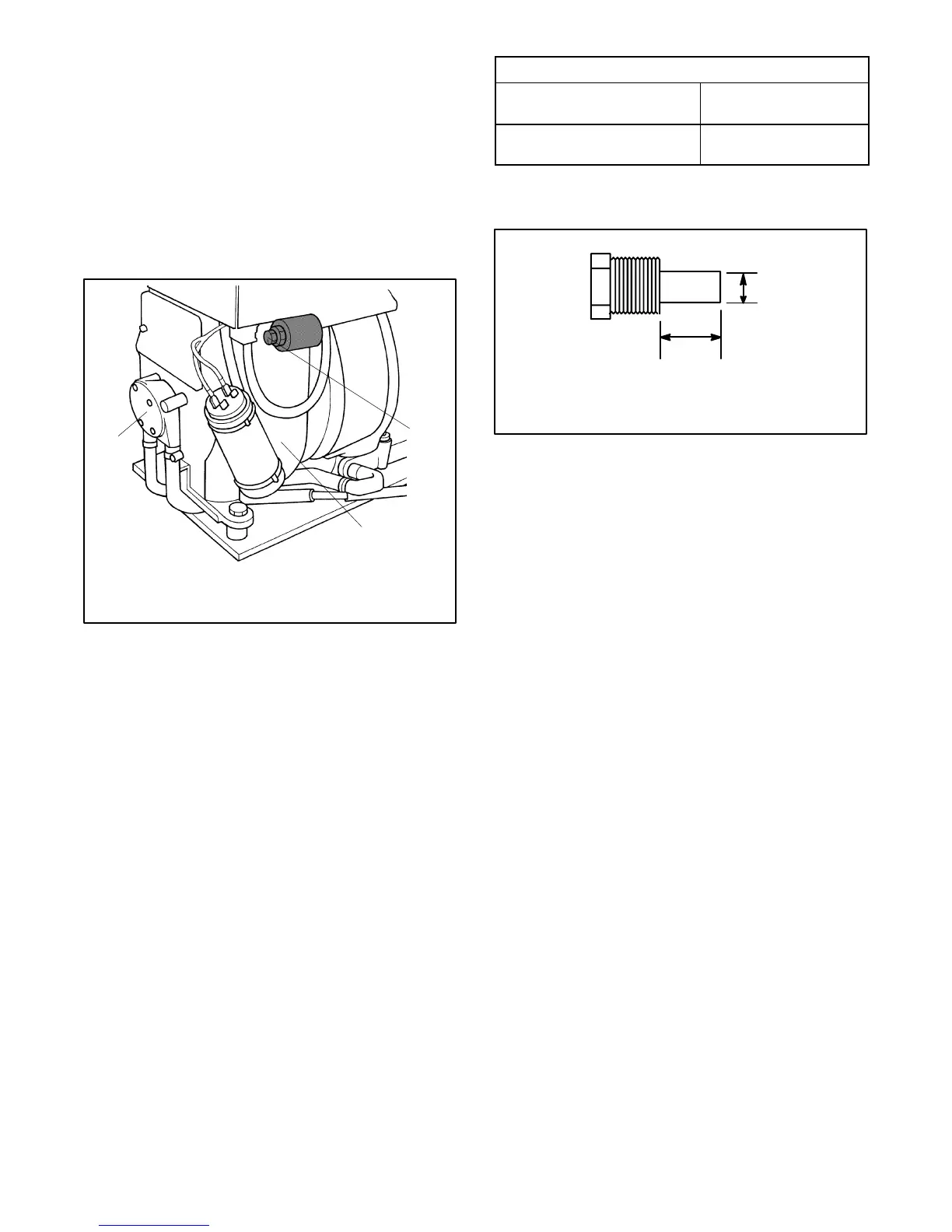

TP-6134

1. Seawater pump

2. Water-cooled alternator

3. Anticorrosion zinc anode (seawater drain)

1

2

3

Figure 6-7 Anticorrosion Zinc Anode

Anticorrosion Zinc Anode Replacement

1. With the generator set cooled, close the seacock,

open the petcock on the engine, and drain the

coolant into a suitable container.

2. Remove the anticorrosion zinc anode (plug).

3. Use a wire brush to remove the loose corrosion on

the anticorrosion zinc anode. Replace the anode

according to Figure 6-8 and Figure 6-9.

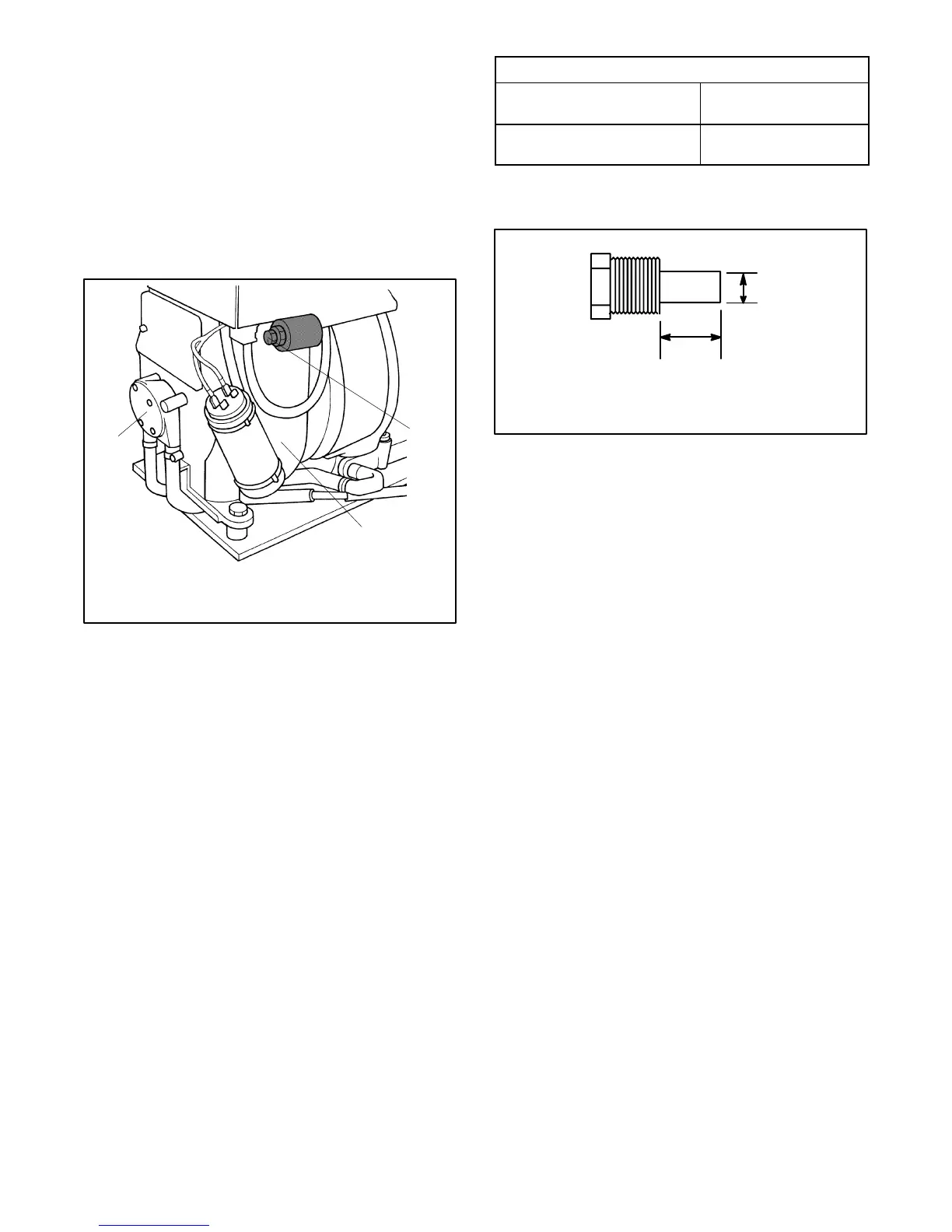

Anticorrosion Zinc Anode Replacement

New Anode

Dimensions mm (in.)

Replace When Percent

of Zinc Remaining Is:

10 (0.39) x 20 (0.79)

<50% of

length/diameter

Figure 6-8 Anticorrosion Zinc Anode (Plug)

Measurements

TP-5586-3

1

2

1. Diameter: 9.5 mm (0.375 in.)

2. Length: 19.05 mm (0.75 in.)

Figure 6-9 Anticorrosion Zinc Anode (Plug)

4. If necessary, cut the anticorrosion zinc to the

correct length. Clean the threaded hole of the

engine and coat the threads of the anticorrosion

zinc anode (plug) with pipe sealant suitable for

marine applications. Install the anticorrosion zinc

anode into the threaded hole.

5. Close the petcock on the engine and open the

seacock.

6. Refill the seawater cooling system.

7. Start the generator set and check for leaks at the

anticorrosion zinc anode location. The pump is

operating if the cooling water flows from the

exhaust outlet. If water is not discharging at the

exhaust outlet, see Section 2, Prestart Checklist,

Seawater Pump Priming in the operation manual.

Loading...

Loading...