TP-6053 7/0420 Section 5 Cooling System

5.2 Water-Cooled Exhaust

Manifold

Each generator set is equipped with a water-cooled

exhaust manifold. Engine coolant circulates through the

manifold, reducing the amount of heat radiated from the

exhaust into the surrounding area. The engine

thermostat is located in the manifold. See Section 1 for

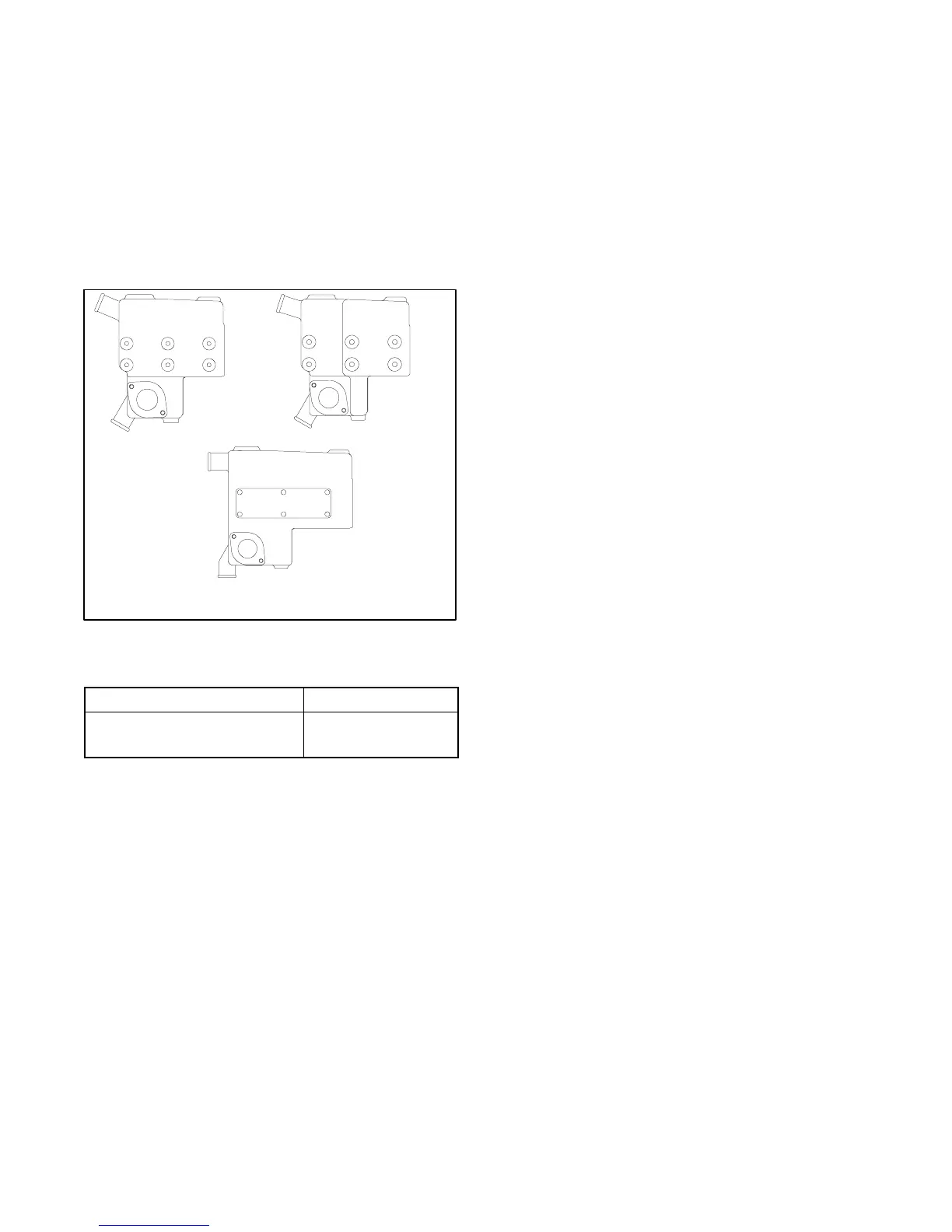

the thermostat location. See Figure 5-2 and Figure 5-3

for exhaust manifold bolt tightening sequence and

torques.

5847316

1

2

3

6

5

4

1

2

3

6

5

4

1

2

3

6

5

4

5EOZ/4EFOZ 8EOZ/6.5EFOZ

9/10EOZ and 8/9EFOZ

Figure 5-2 Water-Cooled Exhaust Manifold Bolt

Tightening Sequence

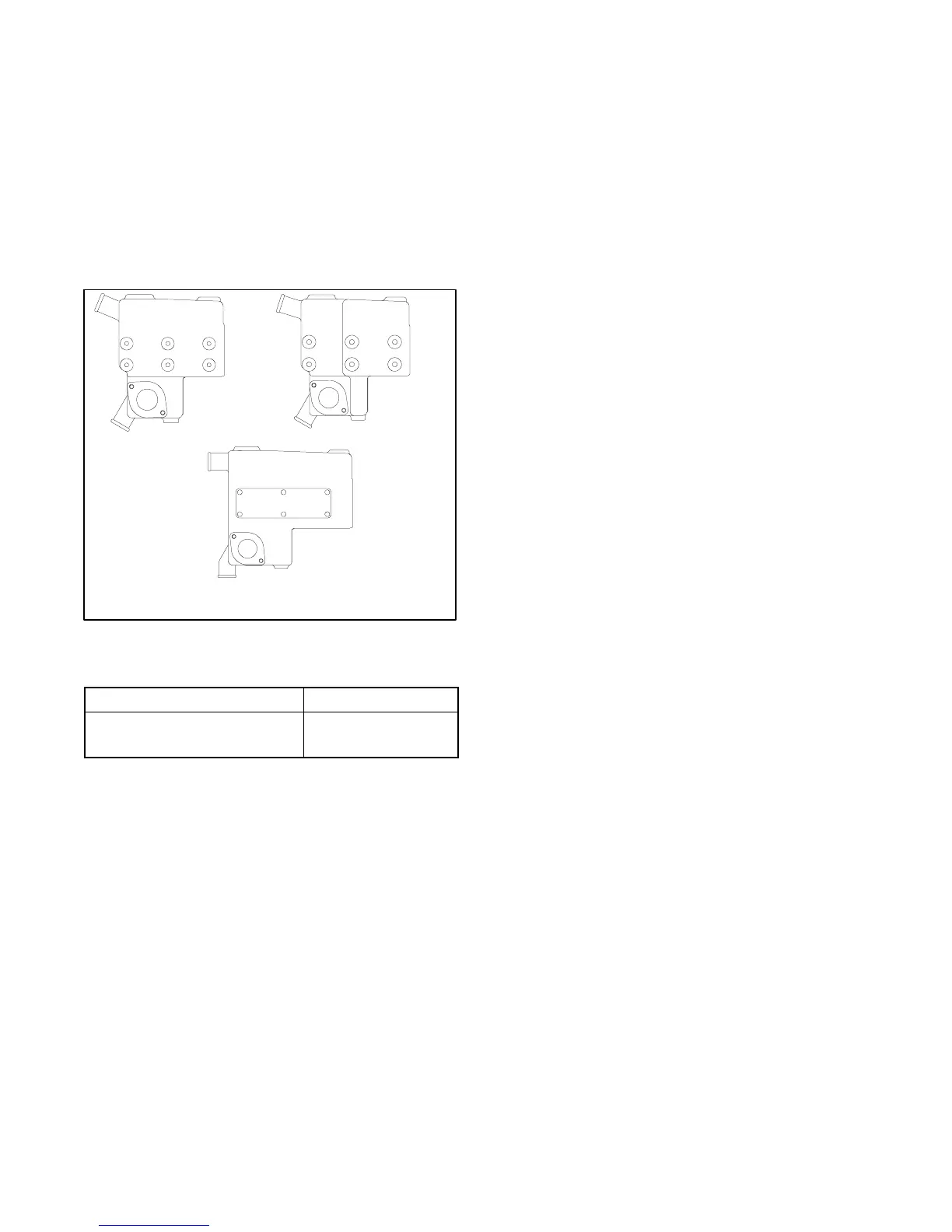

Model Bolt Torque

5EOZ/4EFOZ 8Nm(6ft.lbs.)

8/9/10EOZ and 6.5/8/9EFOZ 19 Nm (14 ft. lbs.)

Figure 5-3 Exhaust Manifold Bolt Tightening Torques

5.3 Closed Heat Exchanger

In a closed cooling system, the seawater circulates

through separate chambers within the heat exchanger

to cool the engine water. The seawater then mixes with

engine exhaust and ejects out the exhaust outlet. See

Section 1.3 for the coolant capacities. Add an additional

0.24 L (8.0 oz.) of coolant to the coolant recovery tank.

5.4 Fill Check and Coolant

Keep the coolant recovery tank approximately 1/4 full.

Before filling the cooling system, close all petcocks and

tighten all hose clamps. Use a solution of 50% ethylene

glycol and 50% clean, softened water to inhibit rust and

corrosion and to prevent freezing. Add additional

coolant mixture, as necessary to the coolant recovery

tank. Periodically check the coolant level on closed

systems by removing the pressure cap. Do not rely

solely on the level in the coolant recovery tank. Add

fresh coolant mixture until the level is just below the

overflow tube opening.

Do not add coolant to a hot engine. Adding coolant to a

hot engine can cause the cylinder block or cylinder head

to crack. Wait until the engine has cooled.

Note: Coolant solution. A coolant solution of 50%

ethylene glycol provides freezing protection to

-- 3 7 _C(--34_F) and overheating protection to

129°C (265°F). A coolant solution with less than

50% ethylene glycol may not provide adequate

freezing and overheating protection. A coolant

solution with more than 50% ethylene glycol can

cause engine or component damage. Do not use

alcohol or methanol antifreeze or mix them with

the specified coolant. Consult the engine

manufacturer’s operation manual for engine

coolant specifications.

5.5 Flush and Clean Cooling

System

For optimum protection, drain, flush, and refill the

cooling system at the interval listed in the operation

manual’s service schedule.

Pay special attention to the coolant level. Check the

coolant level as described earlier.

Flush and Clean Procedure

1. Remove the pipe plug located in the heat

exchanger.

2. Open the petcocks on the engine block and cooling

system and let the system drain completely. Some

models may have petcocks located behind the belt

guard.

3. Remove the pressure cap to simplify draining.

4. Drain, clean, and flush the cooling system,

including the coolant recovery tank, with clean

water.

5. Close the petcocks.

6. Fill the cooling system with recommended coolant.

Loading...

Loading...