TP-6053 7/0424 Section 5 Cooling System

5.10 Anticorrosion Zinc Anode

The heat exchanger contains an anticorrosion zinc

anode (plug) to prevent electrolytic corrosion of

generator components by seawater.

Check and replace the zinc anode at intervals

recommended by the operation manual’s service

schedule.

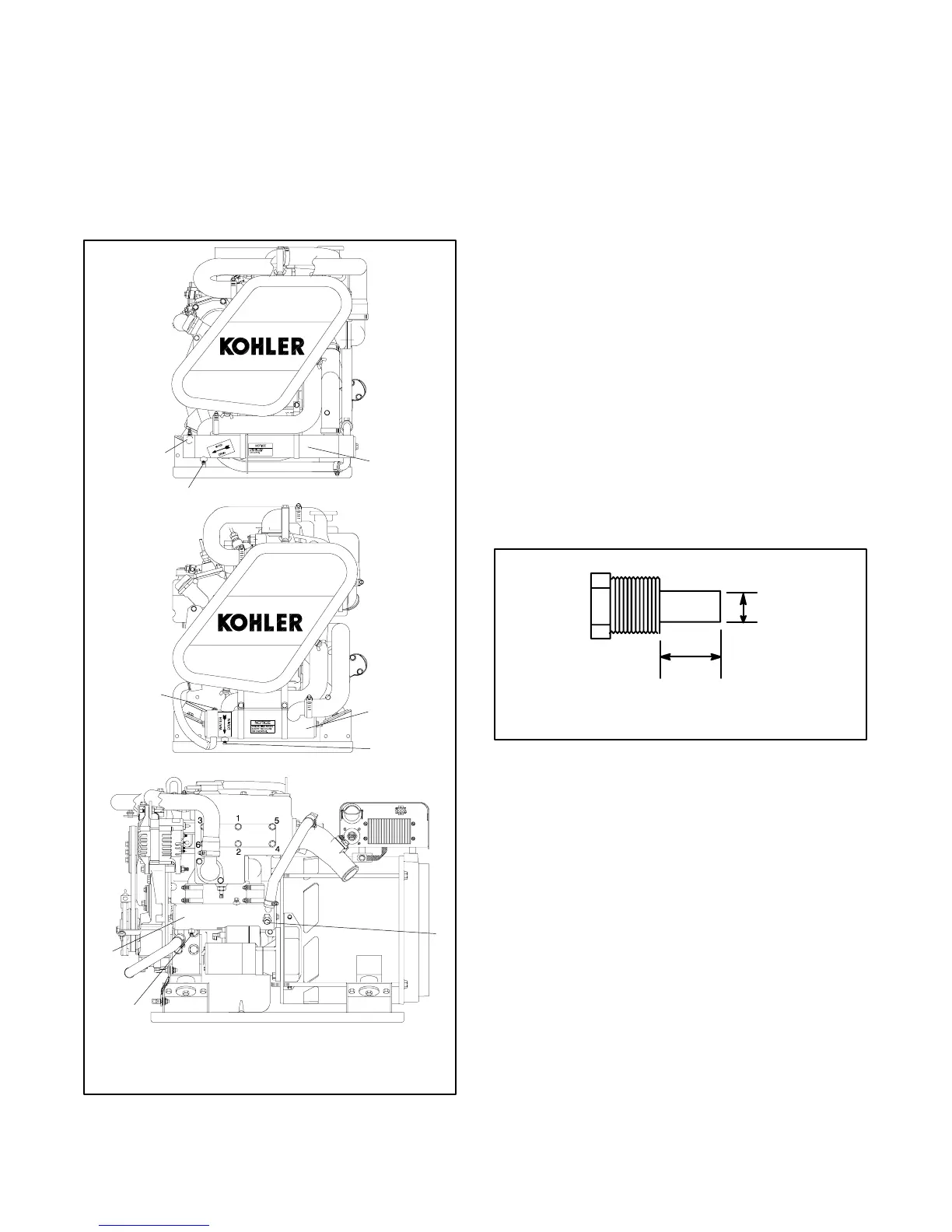

GA-250000C-G

5EOZ/4EFOZ

8EOZ/6.5EFOZ

9/10EOZ and 8/9EFOZ

1

2

3

1

2

3

1

2

3

1. Anticorrosion zinc anode (seawater drain)

2. Heat exchanger

3. Coolant drain

Figure 5-9 Anticorrosion Zinc Anode

Anticorrosion Zinc Anode Replacement Procedure

1. With the generator set cooled, close the seacock,

remove the zinc plug from the heat exchanger, and

drain the coolant into a container.

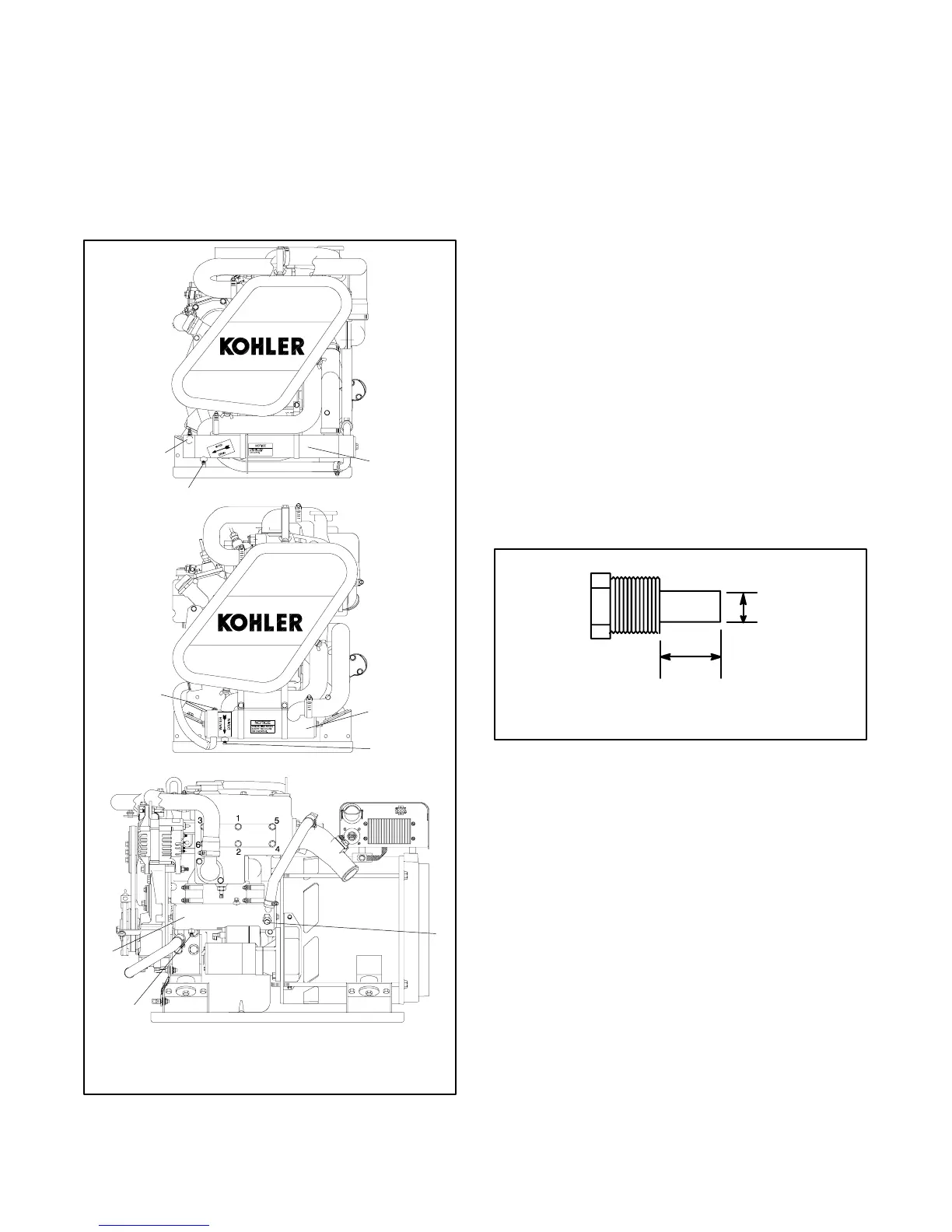

2. Remove the corrosion on the zinc anode. Replace

the anode when the percent of the zinc remaining is

less than 50% of the length and diameter shown in

Figure 5-10.

3. Clean the threaded opening of the heat exchanger

and coat the threads of the zinc anode with pipe

sealant.

4. Install the zinc anode into the heat exchanger.

5. Open the seacock.

6. Refill the cooling system.

7. Start the generator set and check for leaks at the

zinc anode’s location. The pump is operating if

cooling water flows from the exhaust outlet. If water

is not discharging at the exhaust outlet stop the

generator set. For seawater pump priming see the

Prestart Checklist in the operation manual.

TP-5586-3

1

2

1. Diameter: 9 mm (0.34 in.)

2. Length: 43 mm (1.7 in.)

Figure 5-10 Anticorrosion Zinc Anode (Plug)

Loading...

Loading...