8

- 24 -

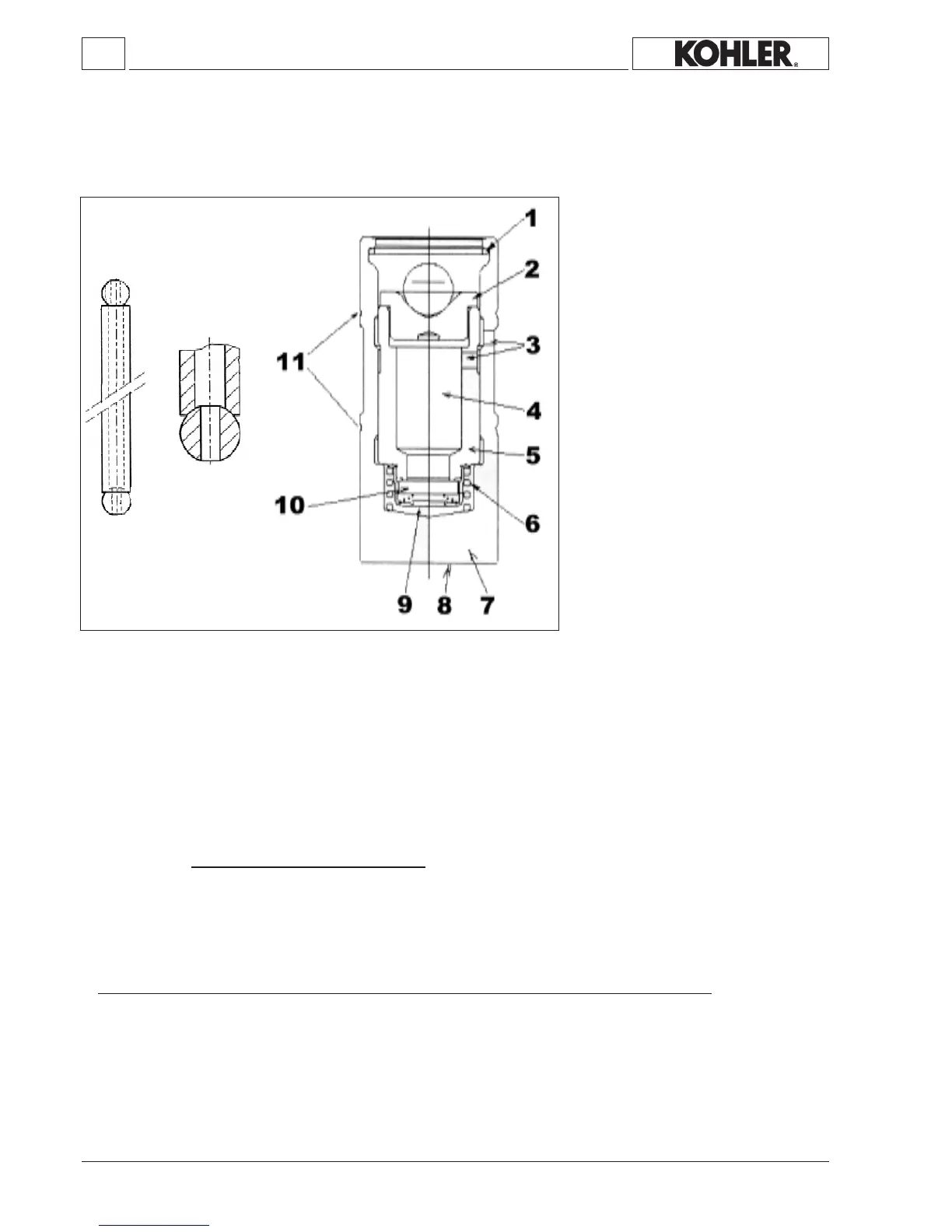

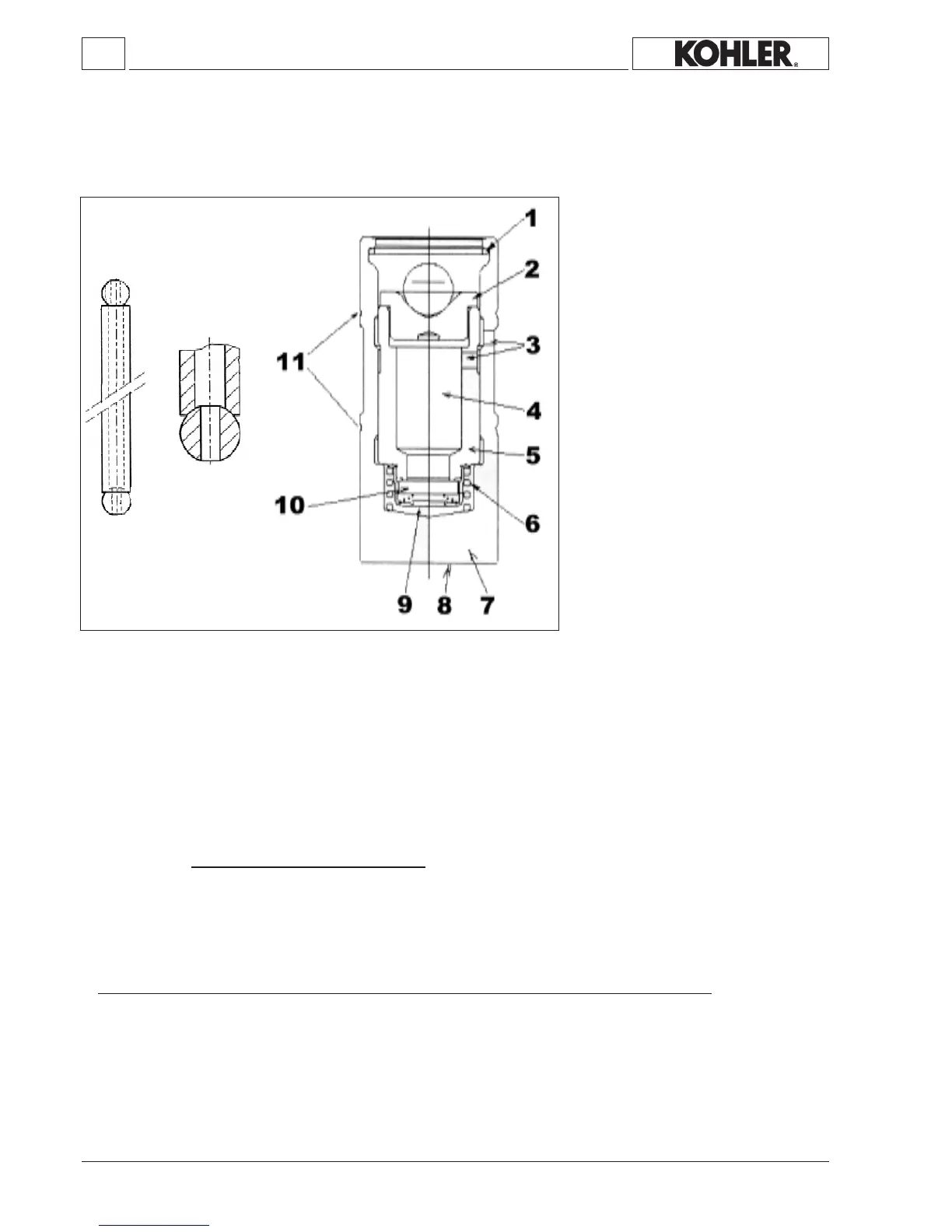

DISASSEMBLY/REASSEMBLY

Caption

1-Lockring

2-Uppercollar

3-Oilinletholes

4-Low-pressurechamber

5-Piston

6-Play-recoveryspring

7-Case

8-Areatobelubricated

9-High-pressurechamber

10-Checkvalve

11-Identicationmarks

Fillthelow-pressurechamberthroughtheoilinletholes.

If clearance occurs while running, as the tappet returns to the base of the camshaft, theplay-recovery spring stretches out,

keepingalltimingsystempartsclosetogether.

While the play-recovery spring is stretching, the check valve lets oil into the high-pressure chamber from the low-pressure

chamber,torecovertheincreaseinvolumeinthehigh-pressurechamber,causedbythestretchingspring.Inthisway,sinceoil

ispracticallyuncontrollable,whenthevalveisnextopened,playwillbecompletelyrecovered.

Duringeachcycleasmallamountofoilisdrawnfromthehigh-pressurechamberintothepistoncouplingwallwiththecaseand

then,passingthroughtheinternalinlethole,owsintothelow-pressurechamber.

Thetappetisshortenedbylessthan0.1mmeachcycle.Thisallowsthetappettomakeupthereductioninplaywhiletheengine

isrunning.

Itisnotnecessaryfortheoiltoreachthetappetonthedownwardstroke:lightpressureisenoughtoensurethatairbubblesdo

notform.

Thetappetmaybesuppliedwiththehigh-pressurechamberfullorempty.Thelow-pressurechamberisalwaysempty.

Thetappetshouldalwaysbehandledinanuprightpositiontopreventthehigh-pressurechamberfromemptying.

Thesurfacethat comesintocontact with thecam should belubricatedgenerously duringassemblyusingAS COMPUND 40

typeMOLYSLIP(seegure).Thisoperationisimportanttoensurecorrectlubricationrightfromthestart.

Thedistributionsystemisassembledasfollows:

a)MakesurethatthepistonisbetweentheBottomDeadCentreandthehalfwaypoint

b)Inserttherodsintopositiononthetappets

c)Mounttherockerarmandthejointblock,thentightenthexingnuttothespeciedtorque

d)DONOTSTARTTHEENGINEFORATLEAST4HOURSAFTERTIGHTENINGTHEROCKERARMSbecausethevalve-

pistoncontactmaybeputatrisk.

Thetappetisunloadedwhenitispossibletoshifttheinternalpartby3.5÷4mmusingaforceof30Nm.

Ifthetappetsareloaded(forexampleiftheyhavebeenleftinahorizontalposition)theenginewillbenoisyduringtherstfew

minutesafterswitchingon,untiltheairhasbeencompletelydrainedoutoftheinsideofthetappetsthemselves.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

Hydraulic tappets KD 400-440

Distributionuseshydraulictappetsforautomaticadjustmentofvalveclearance.

ThegureshowsthetappetusedinKD400engines.

Loading...

Loading...