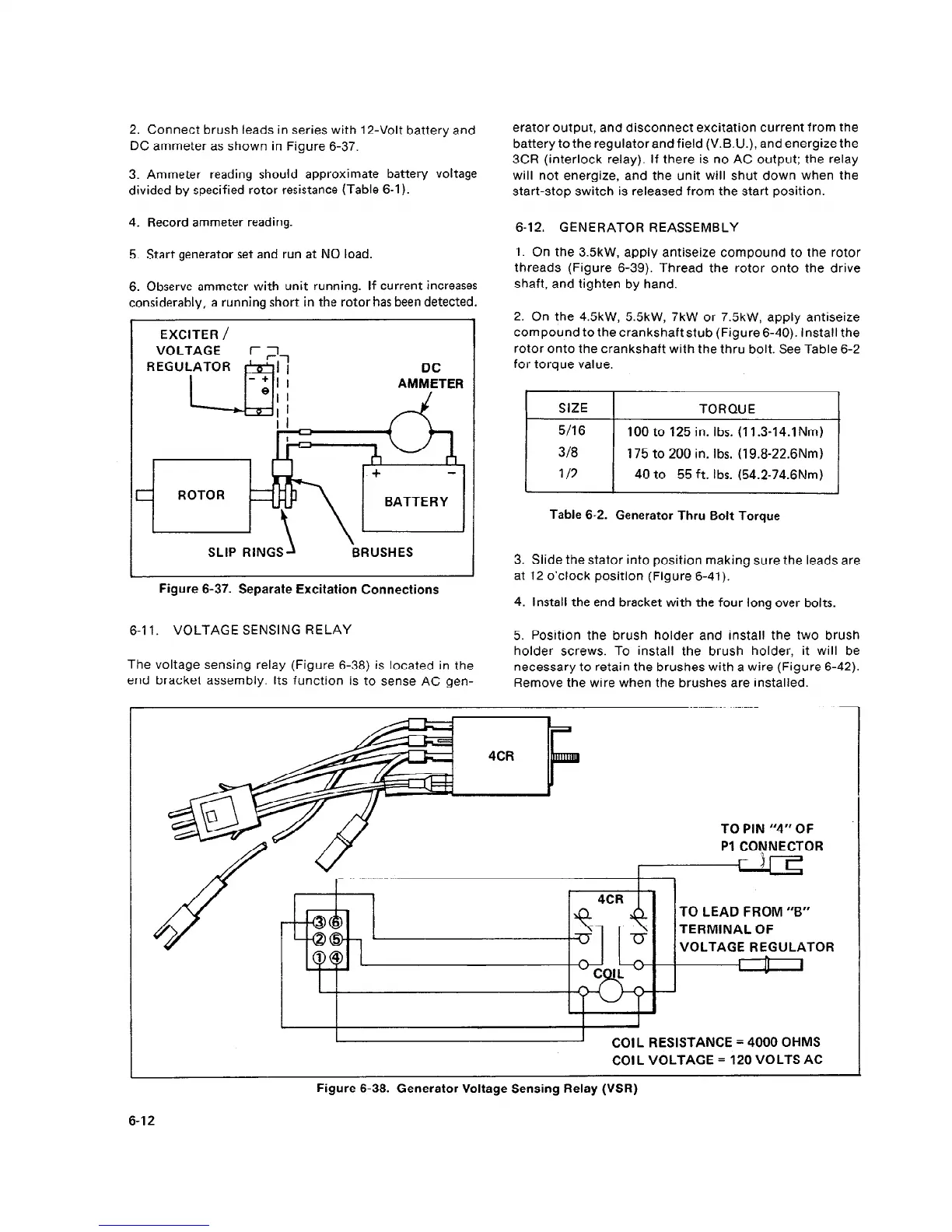

2. Connect brush leads in series with 12-Volt battery and

DC ammeter as shown in Figure 6-37.

3. Ammeter reading should approximate battery voltage

divided by specified rotor resistance (Table 6-1).

4. Record ammeter reading.

5. Start generator set and run at NO load.

6. Observe ammeter with unit running. If current increases

considerably, a running short in the rotor has been detected.

EXCITER /

VOLTAGE r 1

REGULATOR ,-‘&I;

DC

BATTERY

SLIP RINGS J BRUSHES

Figure 6-37. Separate Excitation Connections

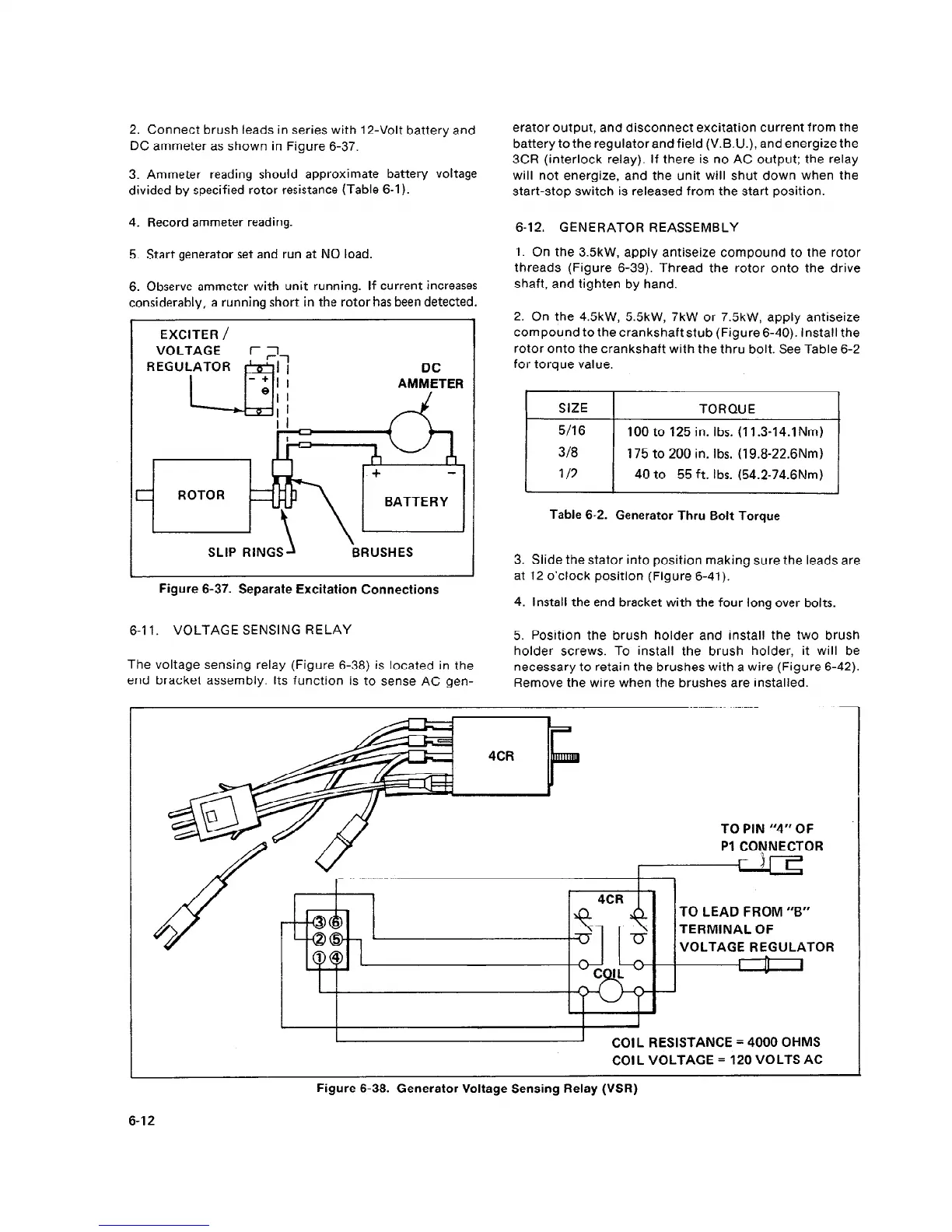

6-l 1. VOLTAGE SENSING RELAY

erator output, and disconnect excitation current from the

battery to the regulator and field (V.B.U.), and energize the

3CR (interlock relay). If there is no AC output; the relay

will not energize, and the unit will shut down when the

start-stop switch is released from the start position.

6-12. GENERATOR REASSEMBLY

1. On the 3.5kW, apply antiseize compound to the rotor

threads (Figure 6-39). Thread the rotor onto the drive

shaft, and tighten by hand.

2. On the 4SkW, 55kW, 7kW or 7.5kW, apply antiseize

compound to the crankshaft stub (Figure 6-40). Install the

rotor onto the crankshaft with the thru bolt. See Table 6-2

for torque value.

I

SIZE

I

TORQUE

I

5116

3/8

l/2

100 to 125 in. Ibs. (11.3-14.1Nm)

175 to 200 in. Ibs. (19.8-22.6Nm)

40 to 55 ft. Ibs. (54.2-74.6Nm)

Table 6-2. Generator Thru Bolt Torque

3. Slide the stator into position making sure the leads are

at 12 o’clock position (Figure 6-41).

4. Install the end bracket with the four long over bolts.

5. Position the brush holder and install the two brush

holder screws. To install the brush holder, it will be

The voltage sensing relay (Figure 6-38) is located in the

necessary to retain the brushes with a wire (Figure 6-42).

end bracket assembly. Its function is to sense AC gen-

Remove the wire when the brushes are installed.

’ TO PIN “4” OF

PI CONNECTOR

TO LEAD FROM “B”

TERMINAL OF

VOLTAGE REGULATOR

I

I

COIL RESISTANCE = 4000 OHMS

COIL VOLTAGE = 120 VOLTS AC

Figure 6-38. Generator Voltage Sensing Relay (VSR)

6-12

Loading...

Loading...