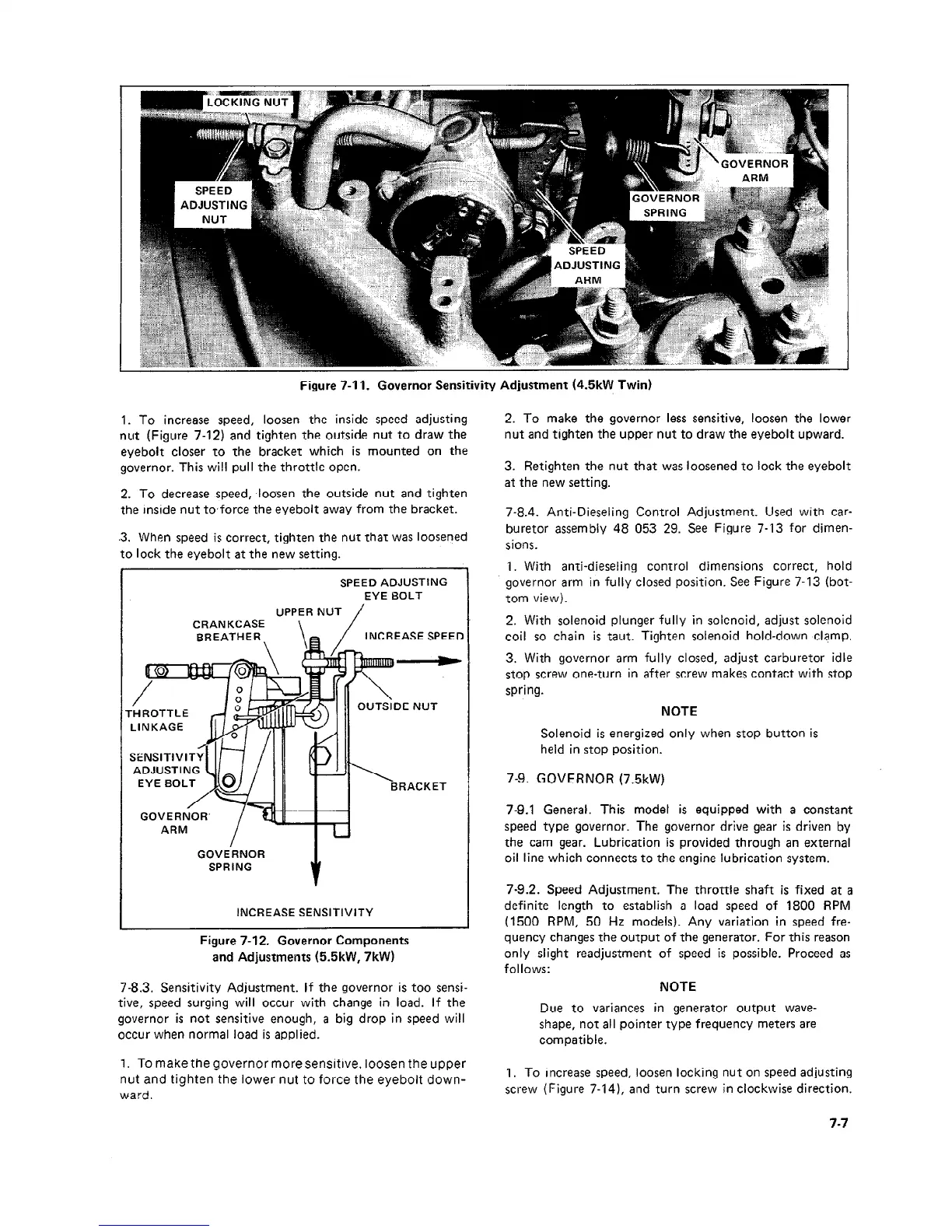

Figure 7-11. Governor Sensitivity Adjustment (4.5kW Twin)

1. To increase speed, loosen the inside speed adjusting

nut (Figure 7-12) and tighten the outside nut to draw the

eyebolt closer to the bracket which is mounted on the

governor. This will pull the throttle open.

2. To decrease speed, ~Ioosen the outside nut and tighten

the inside nut tovforce the eyebolt away from the bracket.

.3. When speed is correct, tighten the nut that was loosened

to lock the eyebolt at the new setting.

SPEED ADJUSTING

EYE BOLT

UPPER NUT

CRANKCASE

BREATHER

INCREASE SPEED

\

DE NUT

THROTTLE /I-VI

LINKAGE

~-??5lll

SENSITIVITY

BRACKET

GOVERNOR’

GOVERNOR

SPRING

INCREASE SENSITIWITY

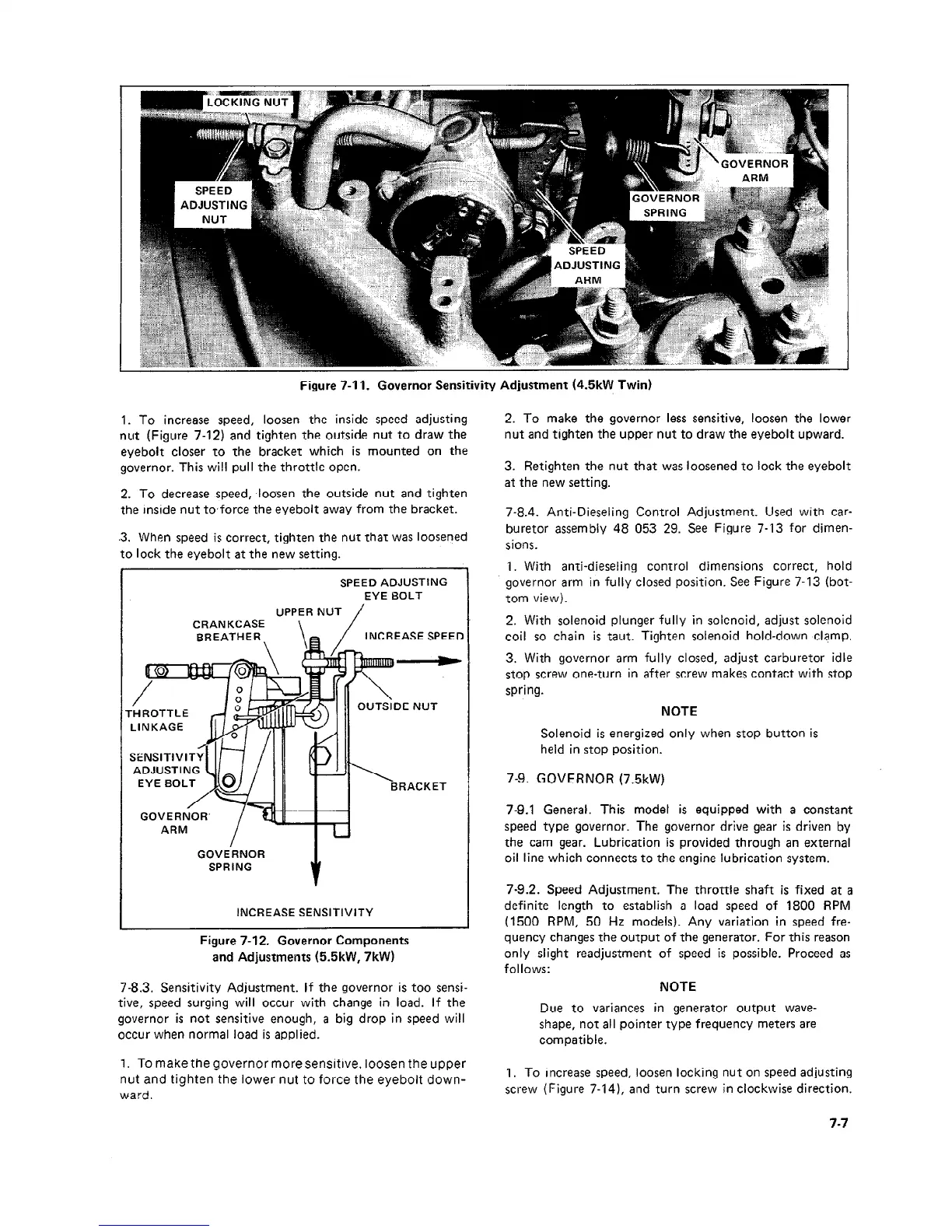

Figure 7-12. Governor Components

and Adjustments (5.5kW, 7kW)

7-8.3. Sensitivity Adjustment. If the governor is too sensi-

tive, speed surging will occur with change in load. If the

governor is not sensitive enough, a big drop in speed will

occur when normal load is applied.

1. To make the governor moresensitive, loosen the upper

nut and tighten the lower nut to force the eyebolt down-

ward.

2. To make the governor less sensitive, loosen the lower

nut and tighten the upper nut to draw the eyebolt upward.

3. Retighten the nut that was loosened to lock the eyebolt

at the new setting.

7-8.4. Anti-Dieseling Control Adjustment. Used with car-

buretor assembly 48 053 29. See Figure 7-13 for dimen-

sions.

1. With anti-dieseling control dimensions correct, hold

governor arm in fully closed position. See Figure 7-13 (bot-

tom view).

2. With solenoid plunger fully in solenoid, adjust solenoid

coil so chain is taut. Tighten solenoid hold-down clamp.

3. With governor arm fully closed, adjust carburetor idle

stop screw one-turn in after screw makes contact with stop

spring.

NOTE

Solenoid is energized only when stop button is

held in stop position.

7-9. GOVERNOR (7.5kW)

7-9.1 General. This model is equipped with a constant

speed type governor. The governor drive gear is driven by

the cam gear. Lubrication is provided through an external

oil line which connects to the engine lubrication system.

79.2. Speed Adjustment. The throttle shaft is fixed at a

definite length to establish a load speed of 1800 RPM

(1500 RPM, 50 Hz models). Any variation in speed fre-

quency changes the output of the generator. For this reason

only slight readjustment of speed is possible. Proceed as

follows:

NOTE

Due to variances in generator output wave-

shape, not all pointer type frequency meters are

compatible.

1. To increase speed, loosen locking nut on speed adjusting

screw (Figure 7-14), and turn screw in clockwise direction.

7-7

Loading...

Loading...