Figure 7-3. Shutdown Control Solenoid (3.5kW-7kW)

2. Lift the solenoid and remove the plunger.

3. Replace the solenoid and retaining bracket and

the main fuel needle. (See Carburetor Adjustment).

readjust

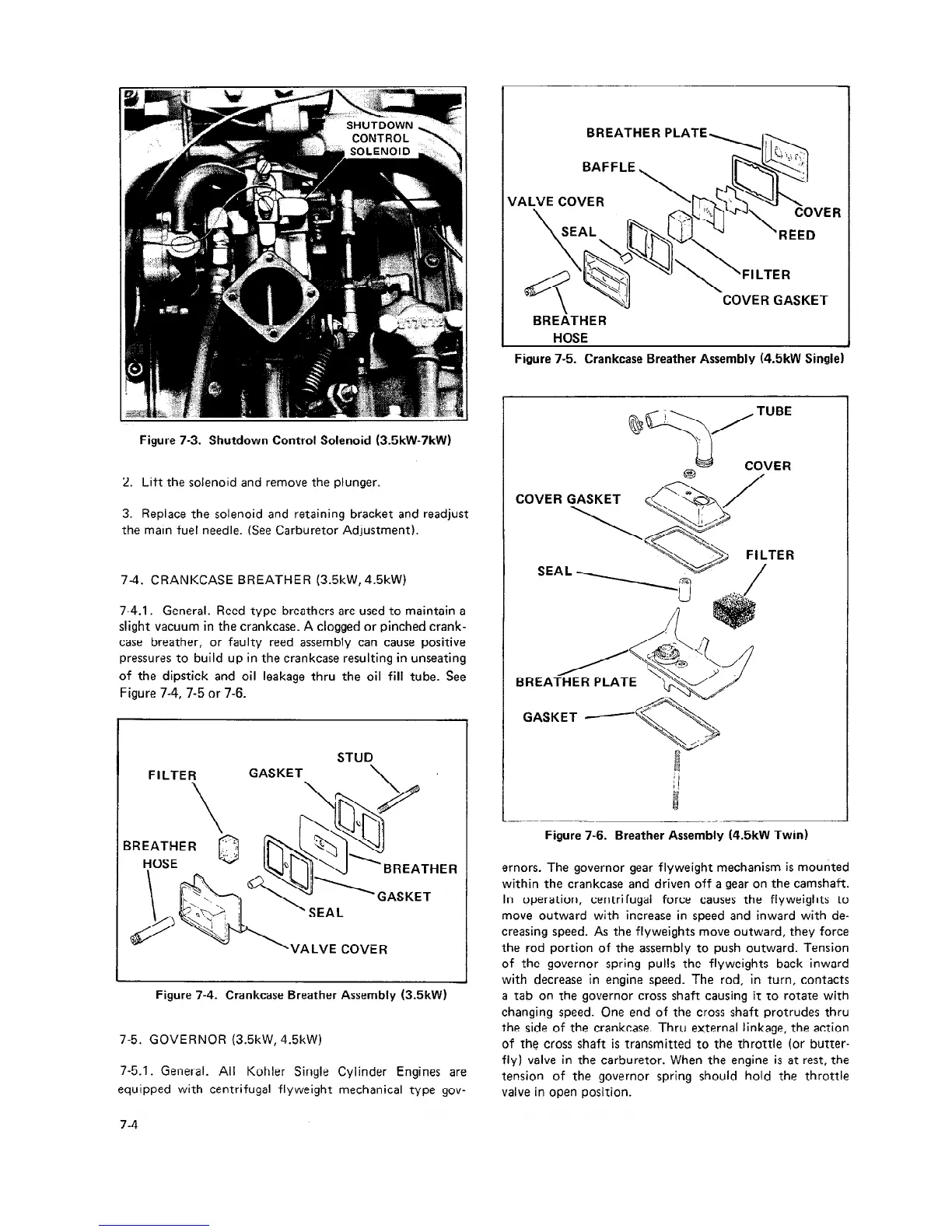

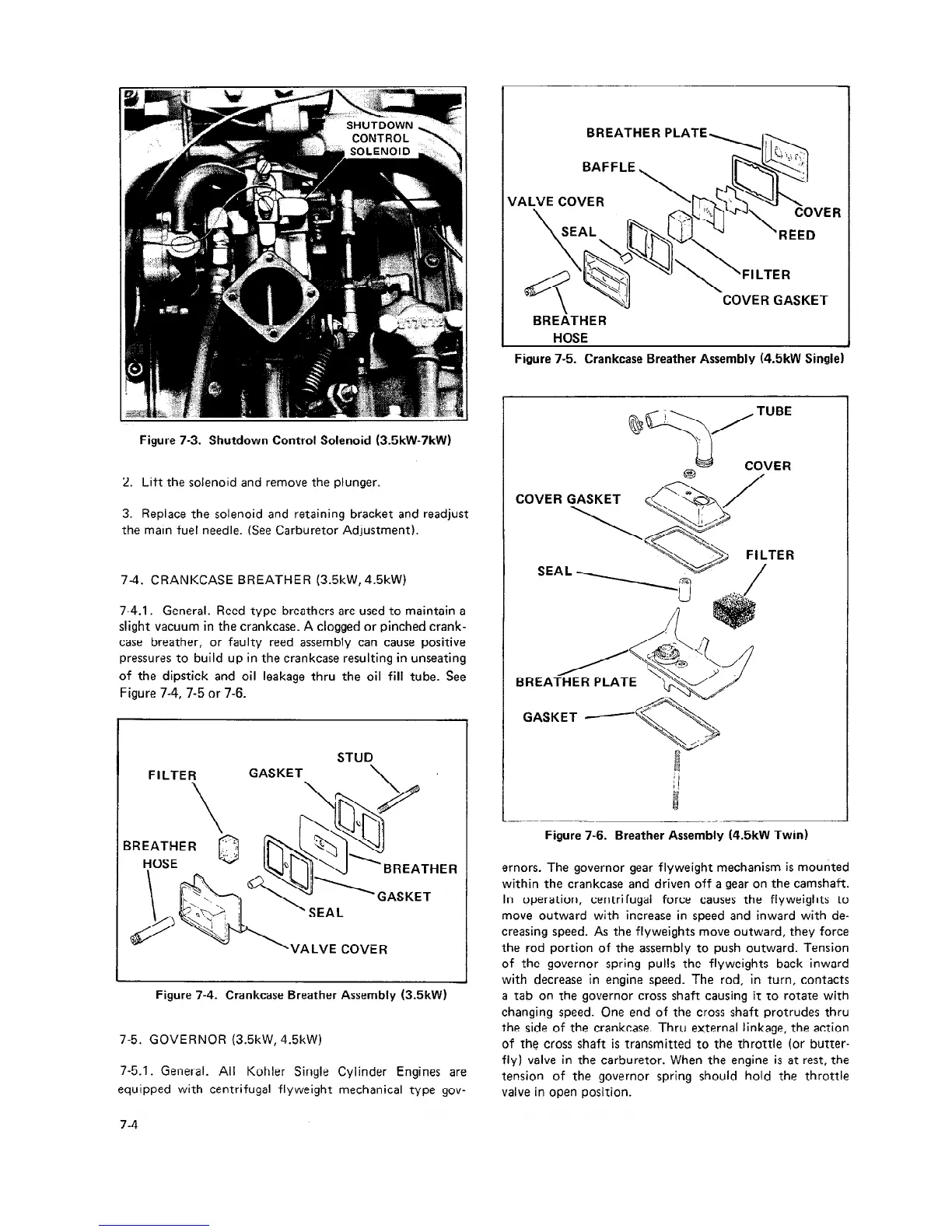

7-4. CRANKCASE BREATHER (3.5kW, 4.5kW)

7-4.1. General. Reed type breathers are used to maintain a

slight vacuum in the crankcase. A clogged or pinched crank-

case breather, or faulty reed assembly can cause positive

pressures to build up in the crankcase resulting in unseating

of the dipstick and oil leakage thru the oil fill tube. See

Figure 7-4, 7-5 or 7-6.

STUD

FILTER

GASKET

\

,

VALVE COVER

Figure 7-4. Crankcase Breather Assembly (3.5kW)

7-5. GOVERNOR (3.5kW, 4.5kW)

7-5.1. General. All Kohler Single Cylinder Engines are

equipped with centrifugal flyweight mechanical type gov-

BREATHER PLATE

VALVE COVER

COVER GASKET

BREATHER

HOSE

Figure 7-5. Crankcase Breather Assembly (4.5kW Single)

COVER GASKET

BREATHER PLATE

GASKET -

Figure 7-6. Breather Assembly (4.5kW Twin)

ernors. The governor gear flyweight mechanism is mounted

within the crankcase and driven off a gear on the camshaft.

In operation,

centrifugal force causes the flyweights to

move outward with increase in speed and inward with de-

creasing speed. As the flyweights move outward, they force

the rod portion of the assembly to push outward. Tension

of the governor spring pulls the flyweights back inward

with decrease in engine speed. The rod, in turn, contacts

a tab on the governor cross shaft causing it to rotate with

changing speed. One end of the cross shaft protrudes thru

the side of the crankcase. Thru external linkage, the action

of the cross shaft is transmitted to the throttle (or butter-

fly) valve in the carburetor. When the engine is at rest, the

tension of the governor spring should hold the throttle

valve in open position.

7-4

Loading...

Loading...