METHOD FOR CHECKING AND REPAIRING

Frequent inspection and prompt repair will reduce repair costs.

The

following items for inspection will serve as a guide to maintenance service of each undercarriage part. Per-

form periodical inspection and contact the Komatsu distributor in your area when machine has approached re-

pairable limits and reversing limits.

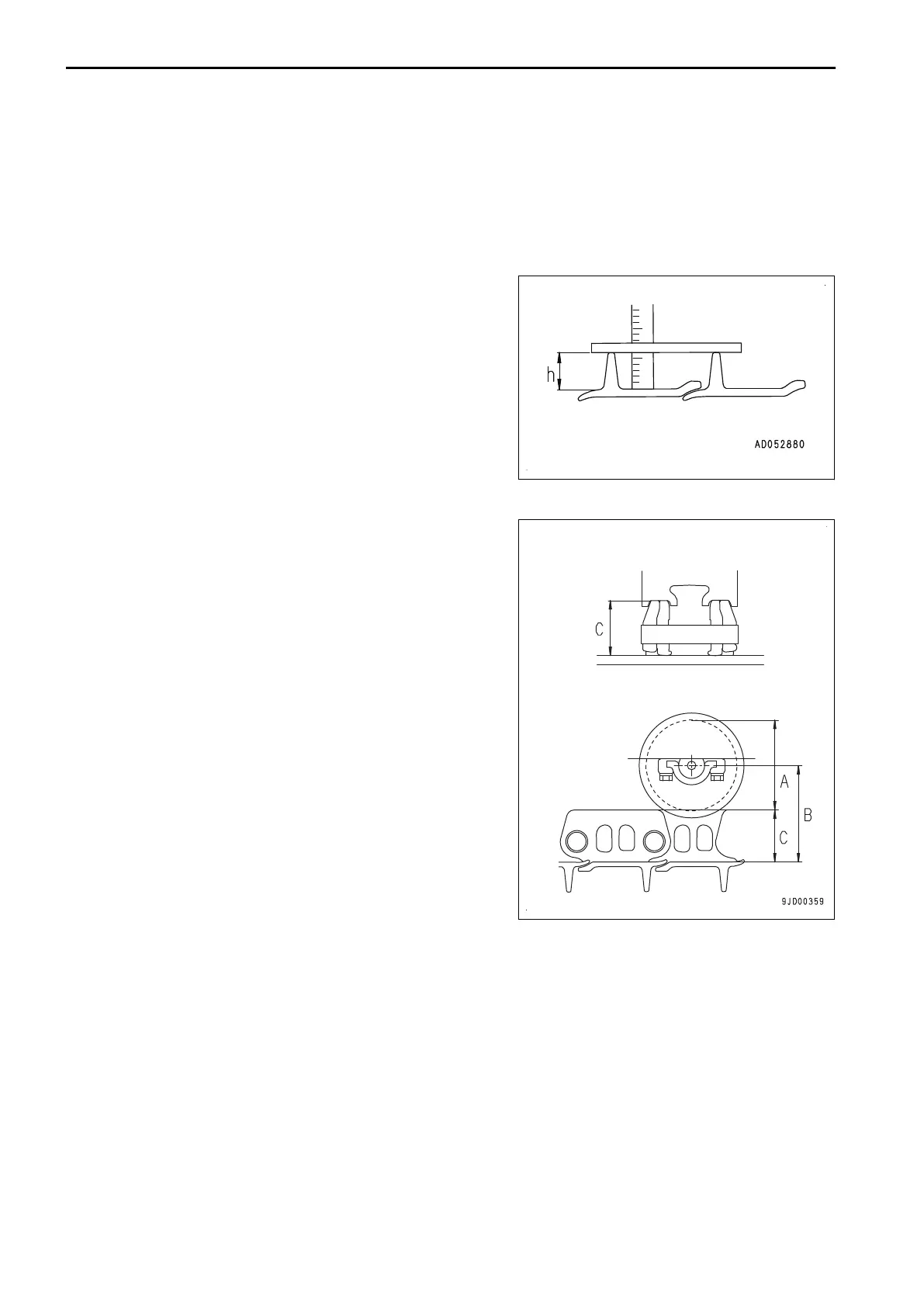

METHOD FOR MEASURE GROUSER HEIGHT

Eliminate the sag of the track, and measure at the center of the

track.

Standard dimension (h): 57.5 mm {2.3 in}

Repairable limit: 16.5 mm {0.6 in}

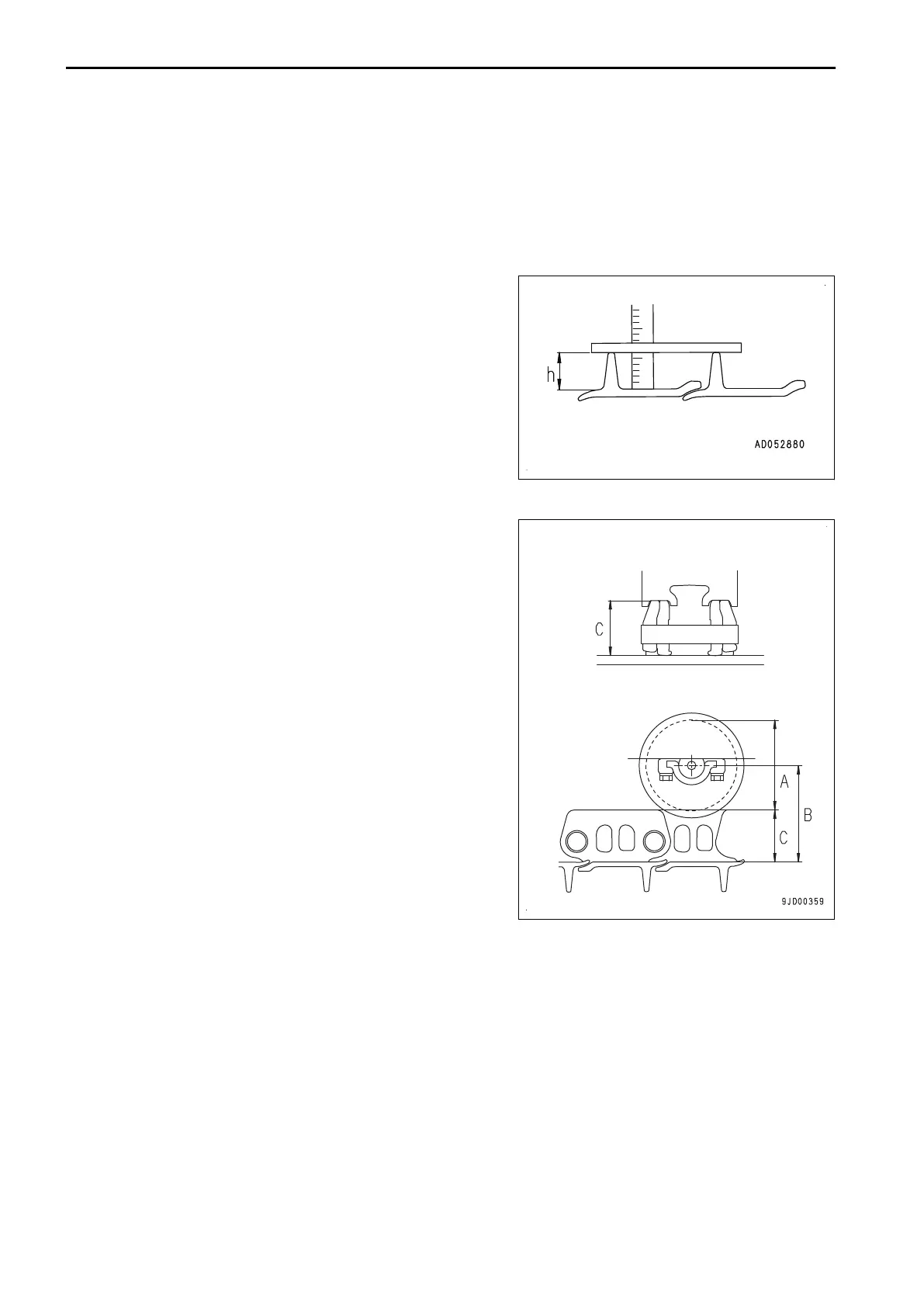

METHOD FOR MEASURING TRACK ROLLER DIAMETER

1.

Measure the link tread (dimension C) as shown in the fig-

ure.

2.

Stop the machine at a position where the link tread, at

which

dimension C was measured, is perfectly in contact

with the roller tread.

3.

Measure dimension B.

4.

Calculate outside diameter of the tread (dimension A).

A = (B - C) x 2

Standard dimension (h): 200 mm {7.9 in}

Repairable limit: 164 mm {6.5 in}

MACHINE OPERATIONS AND CONTROLS OPERATION

3-222

Loading...

Loading...