METHOD FOR RELEASING PRESSURE IN HYDRAULIC CIRCUIT

WARNING

• The

hydraulic system is always under internal pressure. Before checking or replacing the pipes and

hoses, release the pressure from the circuit. If the internal pressure has not been released, the high

pressurized oil may spout out and it may cause serious personal injury or death.

• Immediately after the engine is stopped, its parts and oil are still very hot and may cause burn in-

jury. Wait for the temperature to go down, and then start the work.

• If the oil filler cap is removed without releasing the internal pressure, oil will spurt out, so turn the

oil filler cap slowly to release the internal pressure, then remove it carefully.

NOTICE

Finish

the steps of operating the blade control lever fully forward and backward, and to the right and left

within 15 seconds after the engine has stopped.

1.

Stop the machine.

Place the machine on a firm, level ground.

2.

Lower the work equipment to the ground and stop the engine.

3.

Turn the starting switch to ON position.

4.

Set the work equipment lock lever to FREE position.

5.

Operate the blade control lever fully forward, backward, to the right, and left to release the pressure from

the hydraulic circuit.

6.

Set the work equipment lock lever to LOCK position.

7.

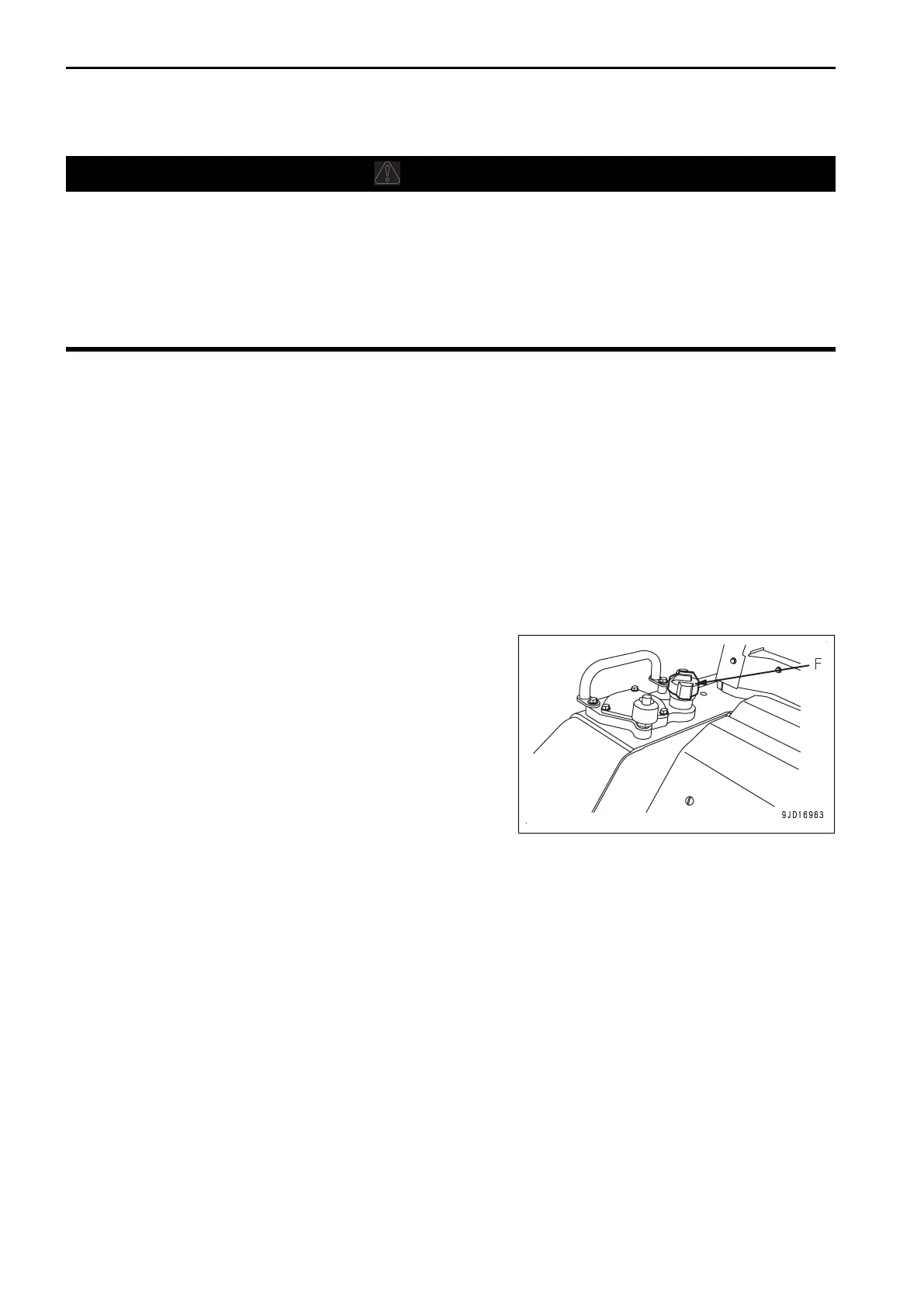

Loosen oil filler cap (F) slowly on the top of the hydraulic

tank to release the internal pressure in the hydraulic tank.

METHOD FOR CHECKING ELECTRICAL INT

AKE AIR HEATER

Check before starting in the cold weather (once a year).

Ask your Komatsu distributor for check of the electrical intake air heater.

MAINTENANCE PROCEDURE MAINTENANCE

4-40

Loading...

Loading...