When the O-ring has been replaced, coat the surface with clean fuel before installing it.

11.

After the packing surface touches the seal surface of the filter cartridge, tighten transparent cup (4) 1/4 to

1/2 turn.

REMARK

If

the transparent cup is fastened too much, the O-ring will be damaged and this leads to leakage of fuel. If

it is too loose, fuel will also leak from gaps of the O-ring. Therefore, be sure to observe the tightening angle.

12.

Clean the filter head.

13.

Fill the new filter cartridge with clean fuel, thinly apply oil to the packing surface, then install it to the filter

head.

NOTICE

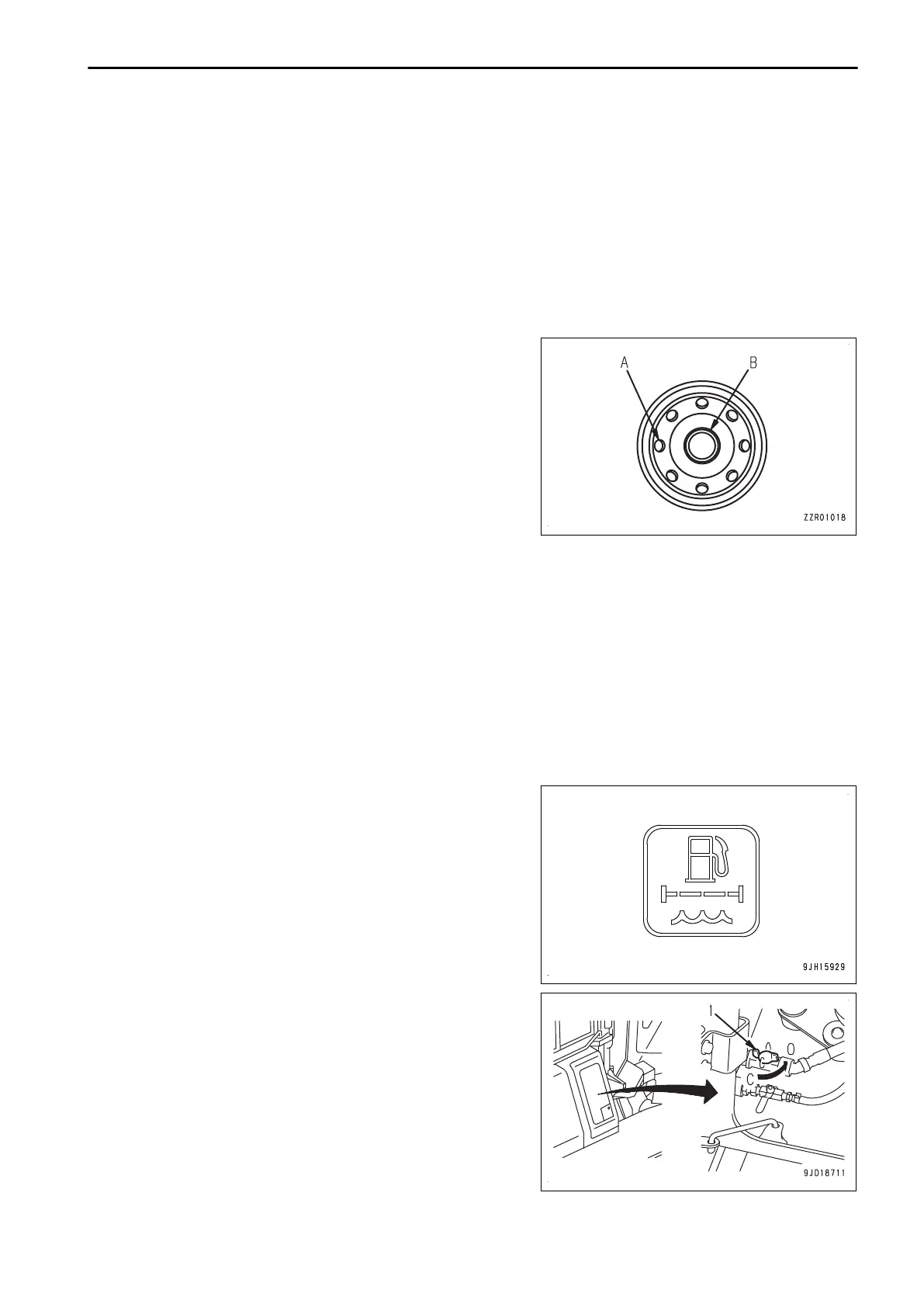

• When

filling the filter cartridge with fuel, do not re-

move cap (B). Always fill with fuel from small

holes (A) (8 places) on the dirty side.

• After filling with fuel, remove cap (B) and install

the fuel filter.

• Always fill with clean fuel. Be careful not to let any

dirt or dust get into the fuel. In particular, center

portion is the clean side, so do not remove cap (B)

when filling with fuel. Be careful not to let dirt or

dust get into the center portion on the clean side.

14.

After the packing surface reaches the sealing surface of the filter head, tighten the filter cartridge 3/4 turns.

REMARK

• If

the filter cartridge is fastened too much, the packing will be damaged and this leads to leakage of

fuel. If the filter cartridge is too loose, fuel will also leak from the packing. Be sure to observe the tight-

ening angle.

• When tightening with a filter wrench, be extremely careful not to dent or damage the filter.

15.

Confirm that drain plug (3) at the bottom of transparent cup (4) is tightened securely.

16.

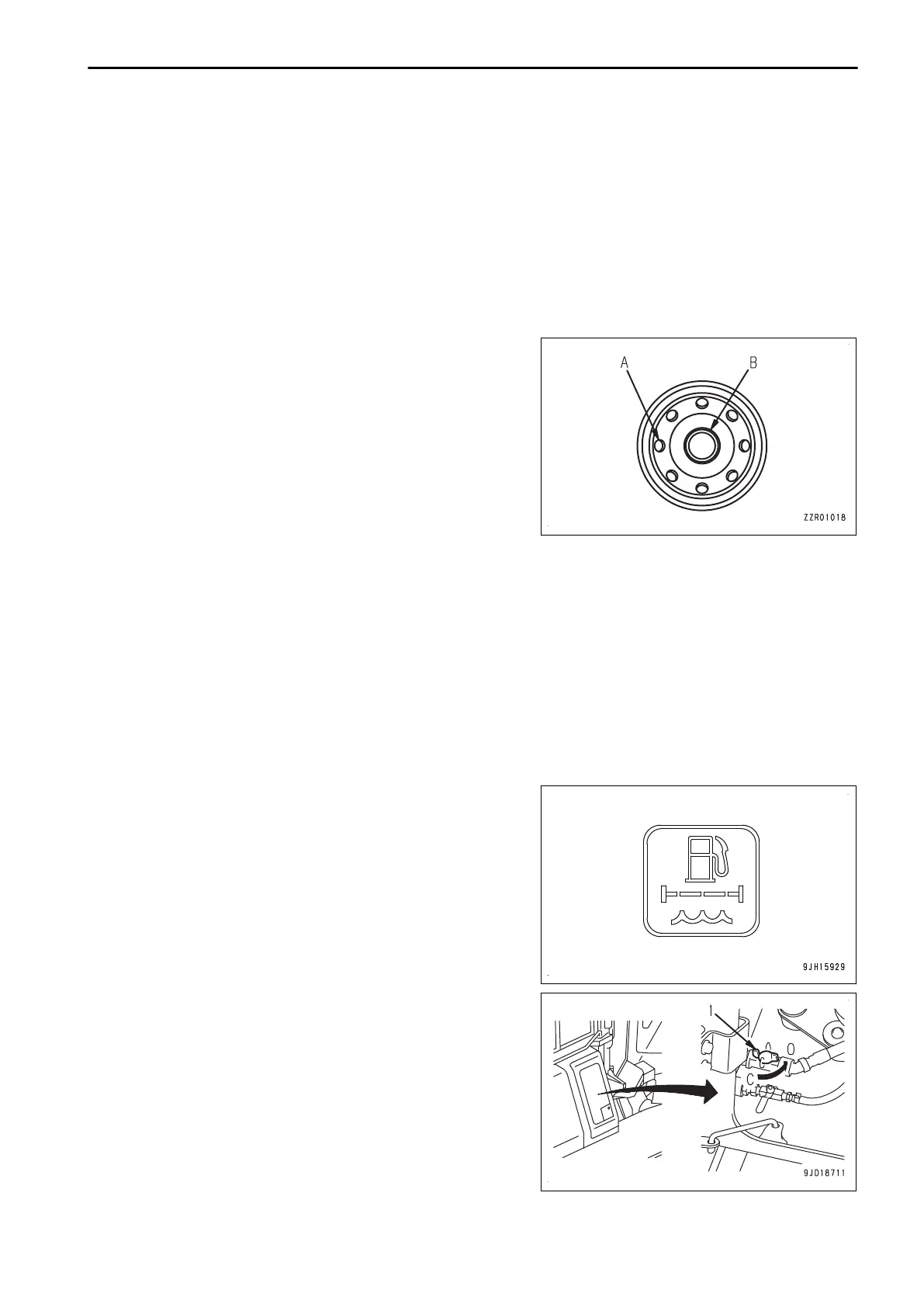

Remove the plastic bag which is wrapping connector (7).

17.

Connect connector (7), and fix clamp (6) of water separator harness.

REMARK

• If

water gets on the connector, the sensor may mal-

function and the water separator caution lamp may

light up. When removing the connector, be extremely

careful not to let water attach to the connector.

• If water attaches to the connector, dry it completely

before connecting it.

18.

Turn fuel supply valve (1) to OPEN position (O).

19.

Bleed air.

1)

Fill up the fuel tank with fuel (to the level where the

float is at the highest position).

MAINTENANCE MAINTENANCE PROCEDURE

4-53

Loading...

Loading...