OPERATION OPERATION

3-96

INSPECTION AND ADJUSTMENT

● Properly adjust track tension.

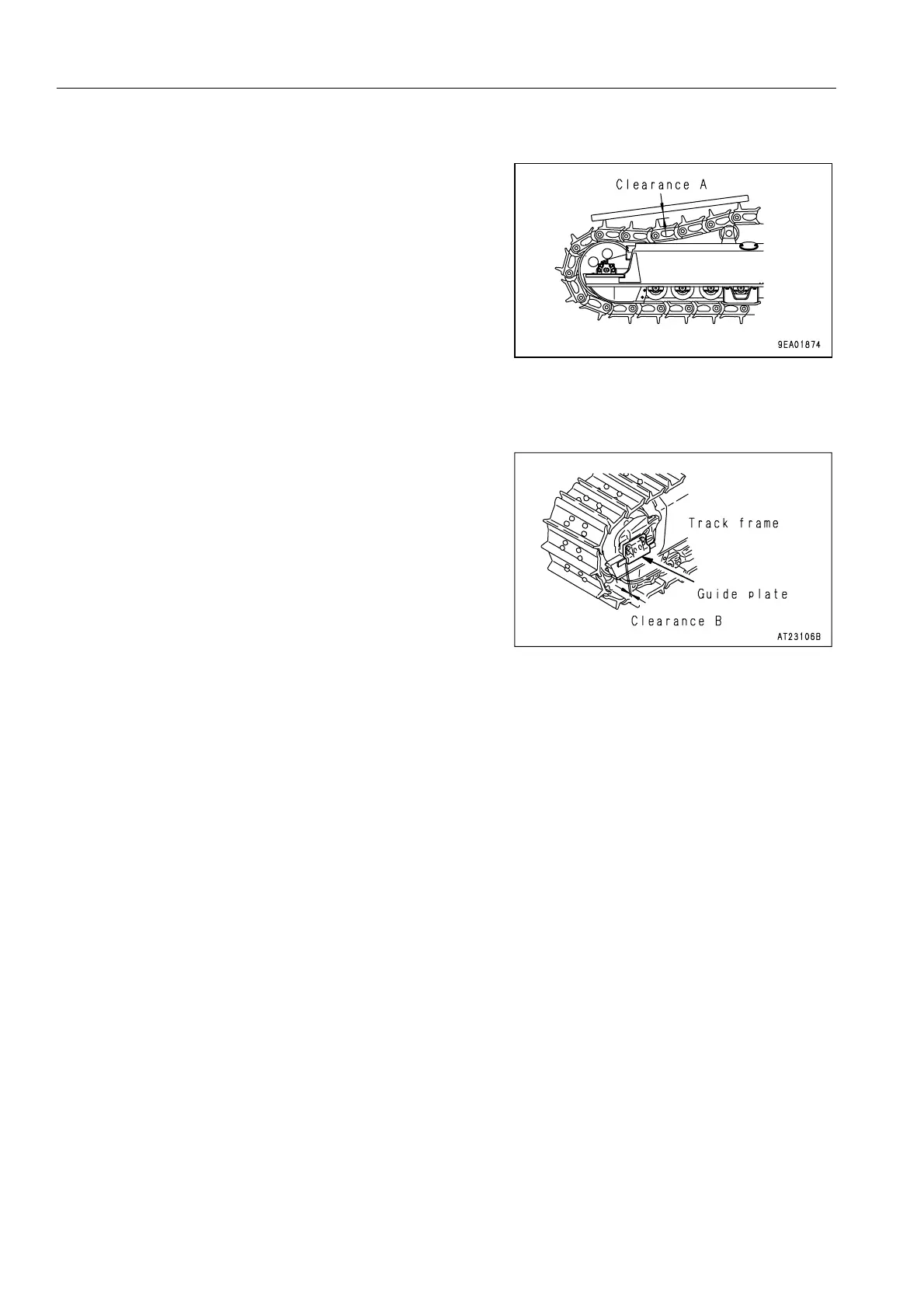

Check the track tension by measuring clearance A

between the idler and carrier roller shown in the figure at

right. Clearance A should be 20 to 30mm (0.8 to 1.2in) nor-

mally. Tense the track a little more for operation on rocky

terrain and loosen it a little for operation on clayey terrain.

Carrying out operations when the track is excessively

loose may cause abnormal vibration and abnormal wear of

the sprocket teeth.

(For inspection and adjustment procedures, refer to

"CHECK TRACK TENSION (PAGE 4-28)").

● Check idler rollers for oil leakage as well as for loose bolts

and nuts. If any trouble is detected, repair immediately.

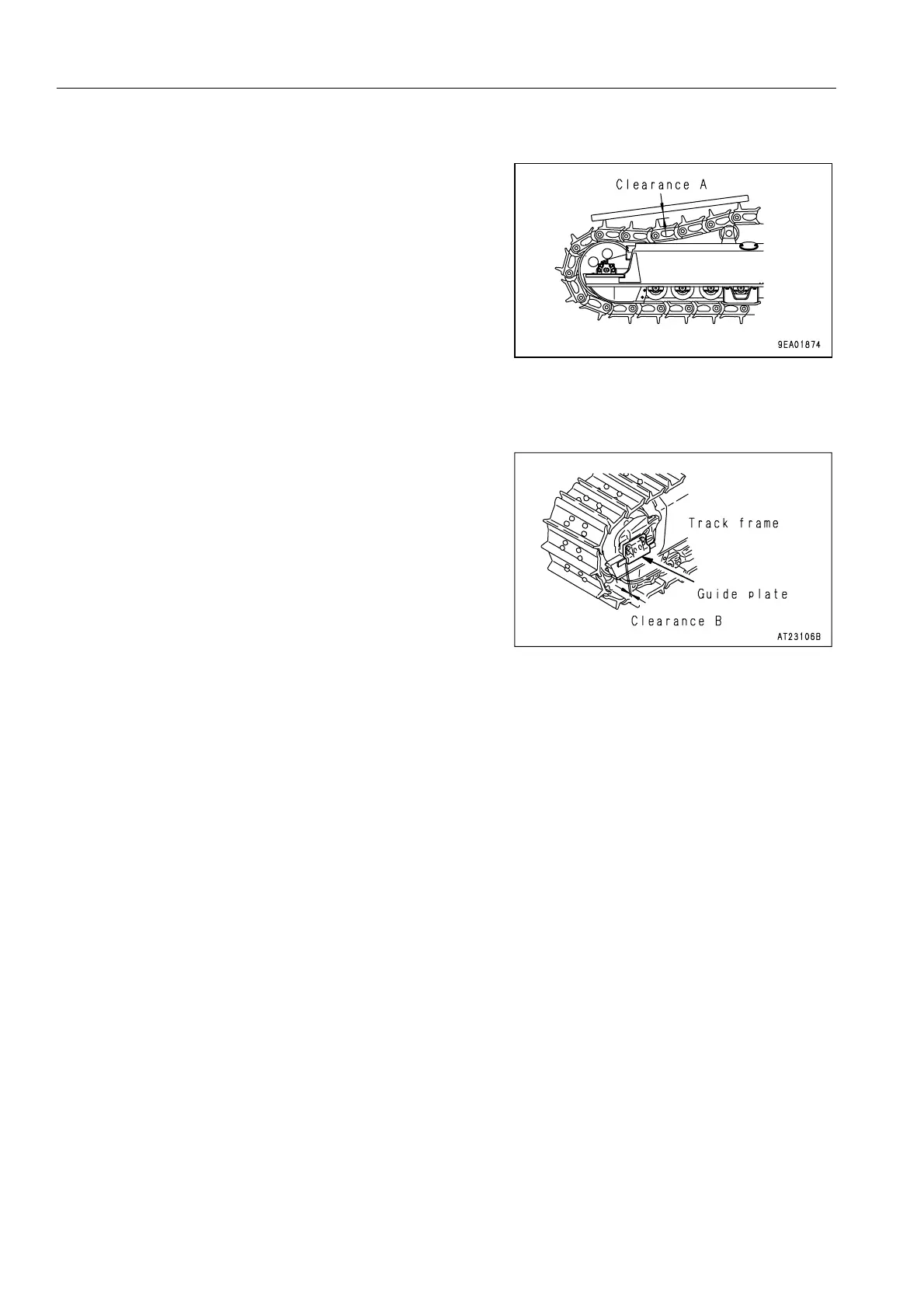

● Check clearance (B) between the idler guide plate and

track frame. If clearance (B) increases, idler may move

sideways and the tracks may come off. (For inspection and

adjustment procedure, refer to "ADJUST IDLER CLEAR-

ANCE (PAGE 4-40)".)

Loading...

Loading...