SERVICE PROCEDURE MAINTENANCE

4-28

CHECK TRACK TENSION

The wear of pins and bushings on the undercarriage will vary with the working conditions and types of soil. It is

thus necessary to continually inspect the track tension so as to maintain the standard tension.

Carry out the check and adjustment under the same conditions as when operating (on jobsites where the track

becomes clogged with mud, measure with the track clogged with mud).

INSPECTION

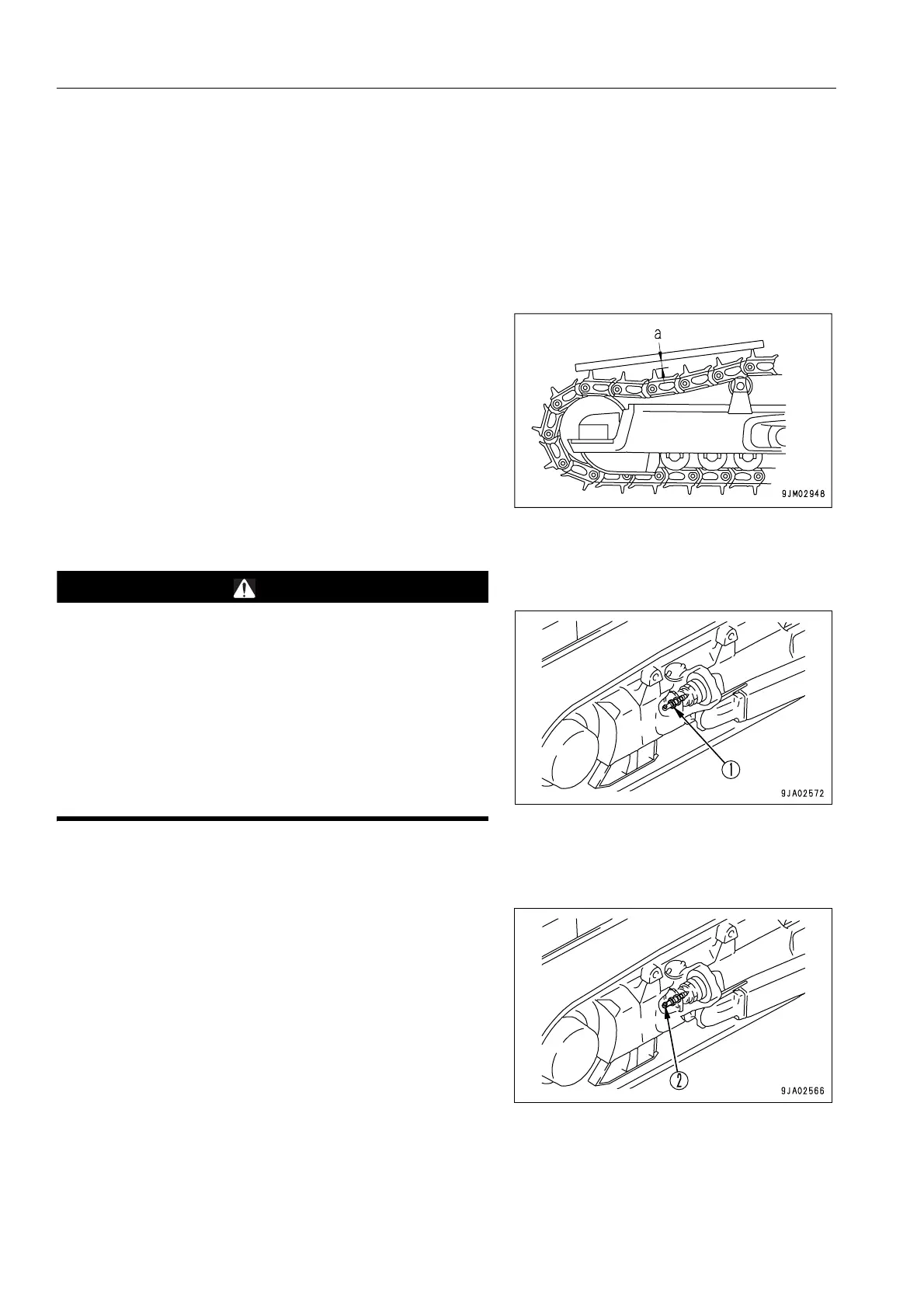

Stop the machine on level ground (stop with the transmission in

FORWARD without applying the brake). Then place a straight

bar on the track shoes between the carrier roller and the idler

as shown in the figure, and measure the clearance between

the bar and the grouser at the midpoint. If the clearance (a) is

20 to 30mm (0.79 to 1.18in), the tension is standard.

If the track tension is not at the standard value, adjust it in the

following manner.

ADJUSTMENT

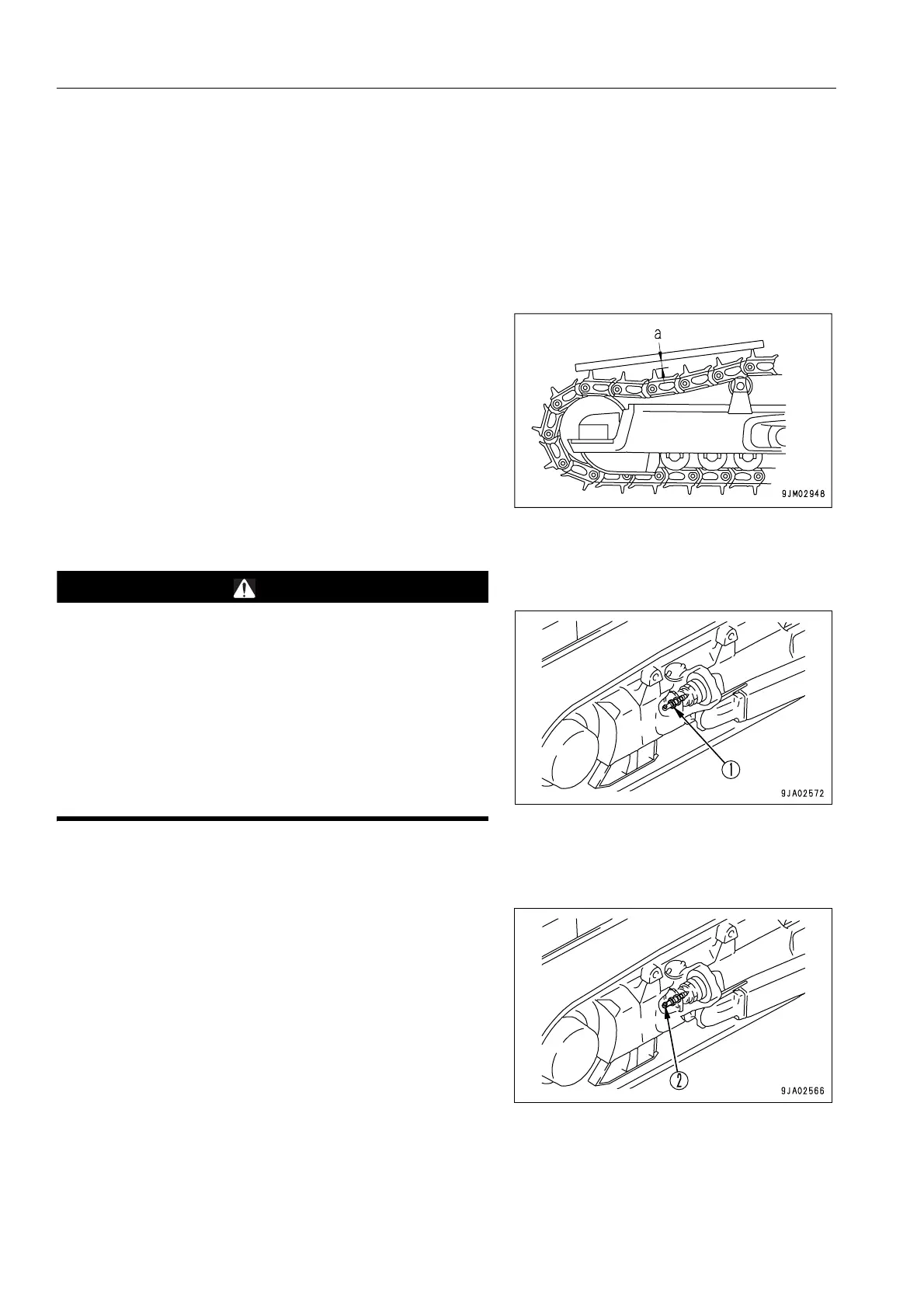

WARNING

Grease inside the adjusting mechanism is under high

pressure. Grease coming from lubricator (1) under pres-

sure can penetrate the body causing injury or death.

For this reason, do not loosen lubricator (1) more than

one turn. Do not loosen any part other than lubricator (1).

Furthermore, do not bring your face in front of the grease

fitting.

If the track tension is not relieved by this procedure,

please contact your Komatsu distributor.

WHEN INCREASING TENSION

Prepare a grease gun.

1. Pump in grease through the grease fitting (2) with a

grease pump.

2. To check that the correct tension has been achieved,

move the machine backwards and forwards.

3. Check the track tension again, and if the tension is not

correct, adjust it again.

Loading...

Loading...