TESTING AND ADJUSTING

20-8 EX20 Series

TIGHTENING OF CYLINDER HEAD

1. TIGHTENING BY ANGLE METHOD

Generally, tightening torque is indicated to tighten each bolt and nut at present. If the bolts and nuts are tightened to

the indicated torque, however, the axial tension is dispersed largely for the indicated torque, however. Accordingly, if a

bolt is tightened to obtain the necessary minimum axial tension, it may be broken at the upper limit value. To obtain

stable axial tension, the elongation of the bolt must be measures as it is tightened. It is impossible, however to apply

this method actually. In the “angle method”, the axial tension is “controlled by the tightening angl”, or by the thread

pitch, which corresponds to the "elongation of the bolt". Dispersion of the axial tension is reduced by tightening the

bolt to the plastic region.

2. TIGHTENING METHOD

(1) Apply “molybdenum disulfide” of “ngine oil” to the threads and seat of each bolt according to the direction.

(2) Tighten the all bolts to the specified “tightening torque”.

(3) Make “marks” on one corner of the bolt and a place corresponding to it, then tighten the bolt to the “specified

angle” as shown below.

At this time, be sure to check by the “marks” that the bolt has been tightened to the specified angle. If this is not

checked, the bolt may be tightened again by the “angle method”. If the bolt is tightened so, it will be broken.

(Note)

• Tighten the bolts in the specified “tightening order”.

• When tightening the bolts by the angle method, do not “retighten” them.

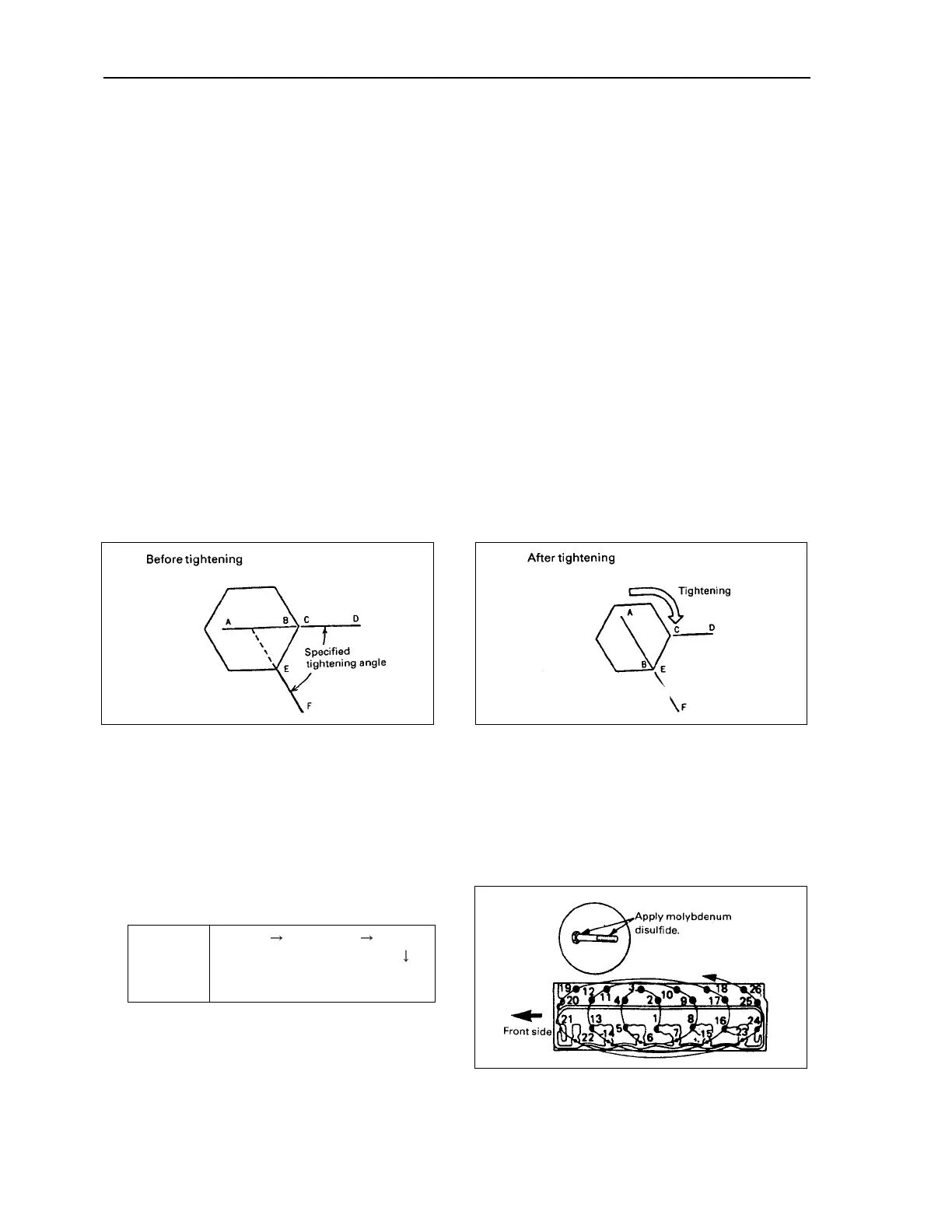

Draw a line passing the center of the bolt (A–B on the bolt

side and C–D on the part side) and a line of the specified

tightening angle from the center of the bolt (E–F) on the

surface of the part to be clamped.

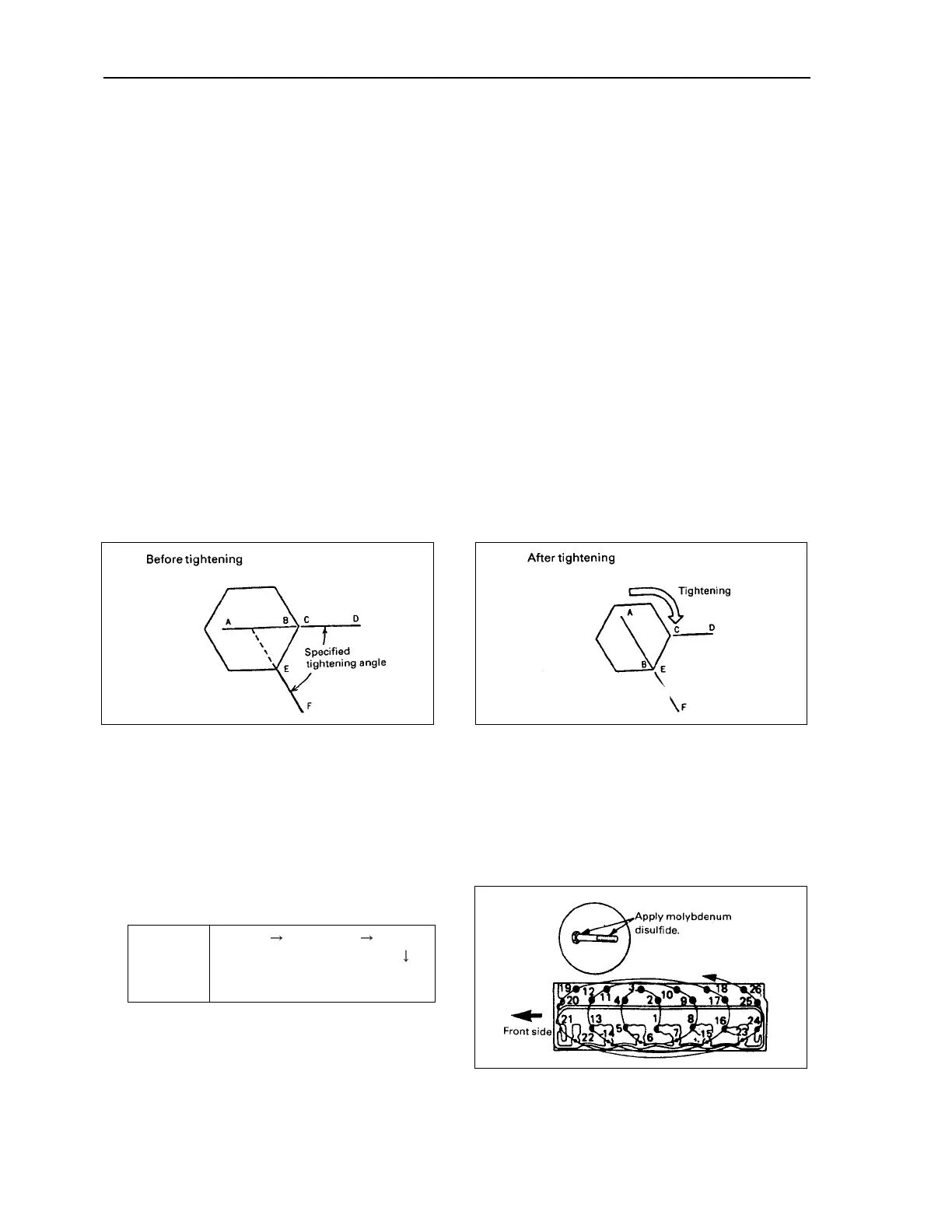

Tighten the bolts in the order shown at the left.

Nm {kgm}

Apply “molybdenum disulfide” to the “seats” and

“threads” of the bolts.

Use shorter bolts (6 pieces) on the nozzle side.

Do not reuse the head bolts more than two times.

Tighten the bolt with a wrench until the line on the bolt

(A–B) is aligned with the line of the specified angle (Line

E–F on the part surface).

Tightening

torque

69 {7.0} Loosen all 88 {9.0}

ޓޓޓޓޓޓޓޓޓޓޓޓޓޓ

90° –120°

TIGHTENING OF CYLINDER HEAD

Loading...

Loading...