TESTING AND ADJUSTING

EX20 Series 20-9

FUEL INJECTION TIMING

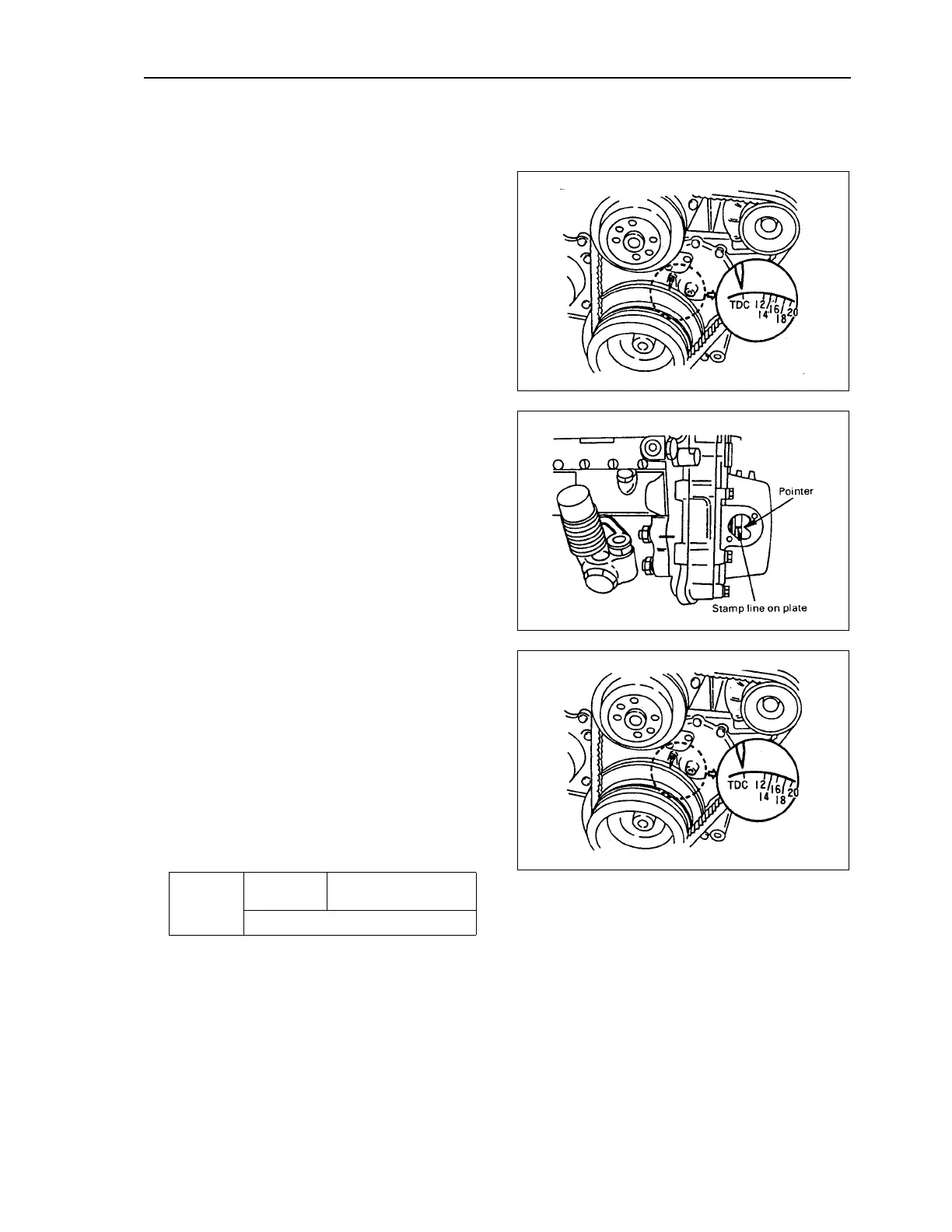

1. TESTING OF INJECTION TIMING (1)

Match the “T.D.C. mark” (top dead center mark)of the

crankshaft pulley to the “pointer”.

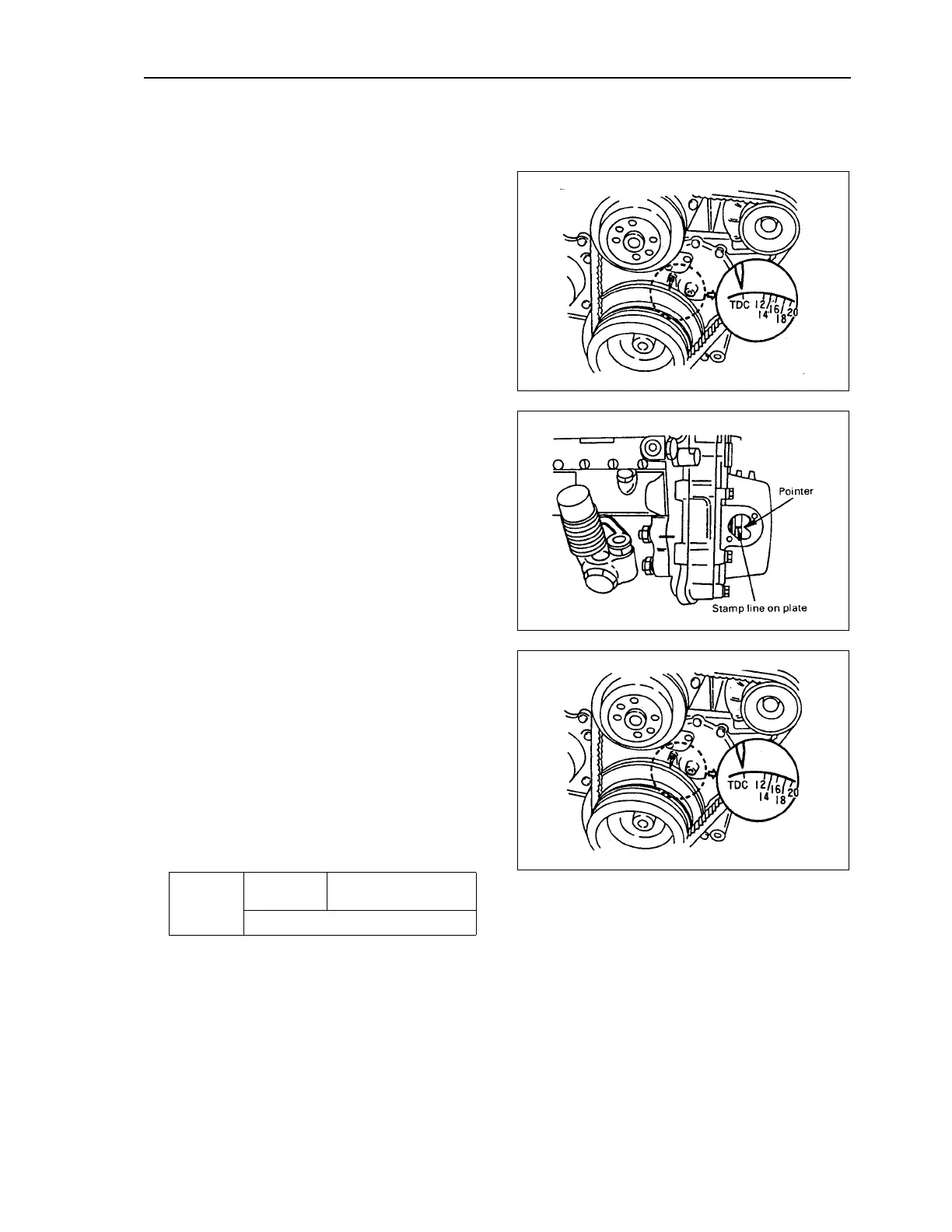

When the “pointer” is matched to the “T.D.C. mark”, if

the stamp line on the injection pump plate is matched

to the pointer on the timing gear case cover, the

injection pump is installed normally.

2. TESTING OF INJECTION TIMING (2)

1) Remove the No. 1 injection pipe, then remove

the No. 1 delivery holder of the injection pump.

Pull out the delivery valve and spring, then

tighten only the holder to 39–44 Nm {4.0–4.5

kgm}.

2) Rotate the crank pulley about 30 degrees coun-

terclockwise from the “T.D.C. mark”.

3) Operating the feed pump by the hand, slowly

rotate the crank pulley clockwise, and the dis-

charge of fuel from the No. 1 delivery holder of

the injection pump is reduced to zero.

4) At the point where the discharge of fuel stops

(injection timing), check the mark of the crank

pulley indicated by the pointer tip.

5) Clean the removed delivery valve and spring,

then install them again and tighten the delivery

holder to the “specified torque”. If the tightening

torque of 39–44 Nm {4.0–4.5 kgm} is not

observed, hunting and other troubles may occur.

6) When removing and installing the delivery valve

and spring, take care that dust does not enter

the openings.

Injection

timing

6BG1T

(Isuzu)

6° (TRL-01), 8° (TRL)

(BTDC)

If deviation exceeds ± 2°, adjust it.

FUEL INJECTION TIMING

Loading...

Loading...