5-41

33. HANDLING AUTO-GREASING SYSTEM

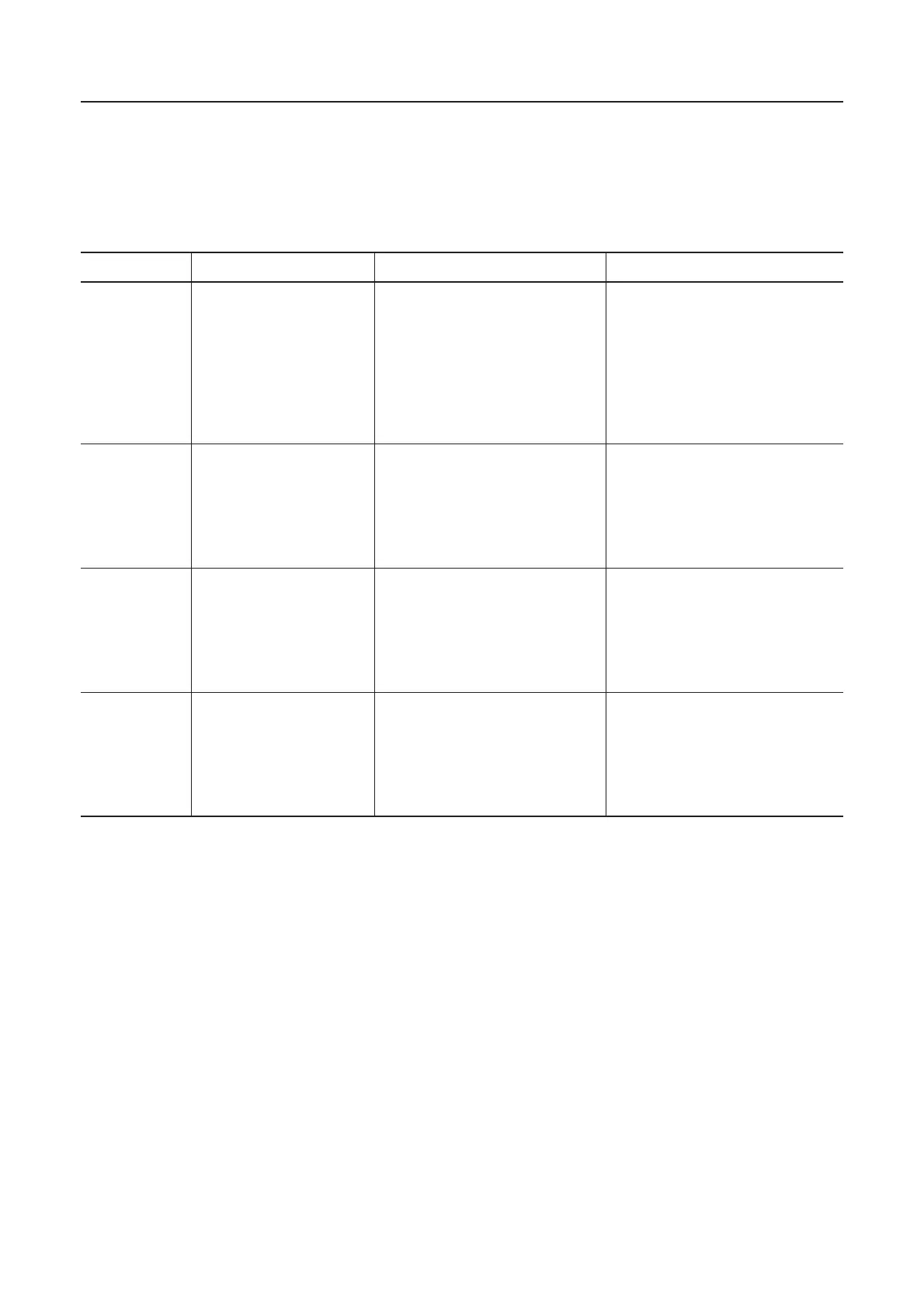

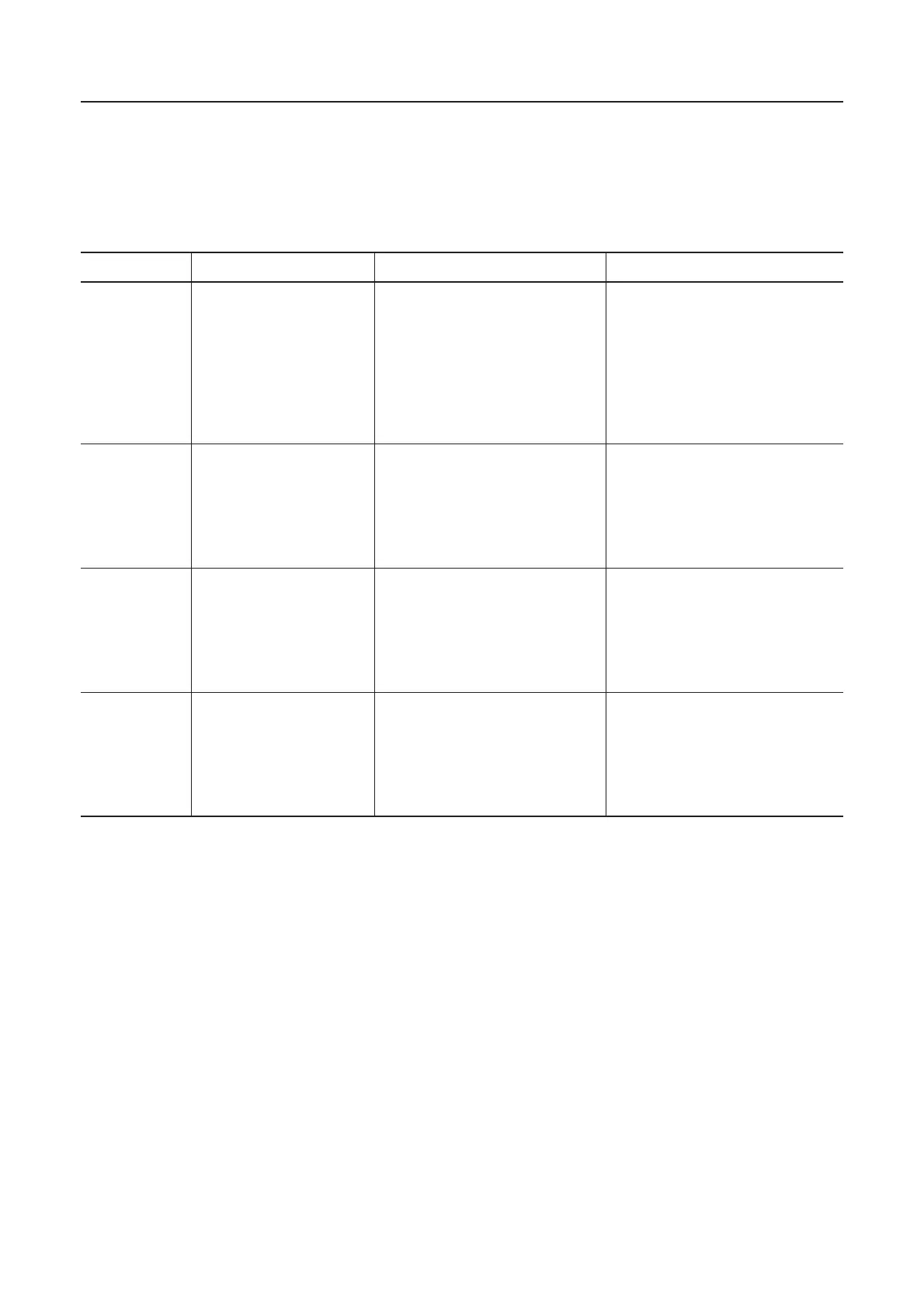

33.3 TROUBLESHOOTING

If any abnormality occurs in the greasing system, the error codes will flash alternately to display the

type of abnormality.

33.4 SPECIFICATIONS

Electric pump

Model: LD10F

Delivery pressure: 24.03 MPa (245 kgf/cm

2

, 3479 PSI) (MAX)

Tank specification: 1000 cc cartridge type

Available temperature range: –20 to 60°C

Applicable grease: NLGI No. 2 to No. 0 lithium-based grease

Rated voltage: DC24V

Rated current: 3A (Note: 6.5A when temperature is –20°C)

Divider valve

Model: LL1

Discharge amount adjustment method: Fixed type

Available pressure: 24.03 MPa (245 kgf/cm

2

, 3479 PSI) (MAX)

Discharge amount: 0.6 – 0.1 cc/st

No. of valves (discharge ports): 1 – 5

Available temperature range: –20 to 60°C

Applicable grease: NLGI No. 2 to No. 0 lithium-based grease

Error code Item Cause Remedy

E ➞ a Defective pressurizing Air in main piping Run pump as necessary and

of pump release grease from end of

piping to bleed air

Air inside pump Release grease from air bleed

in pump to bleed air

Grease tank is empty Add grease

Grease leaking from main Check, tighten connections of

piping main piping (including hoses)

E ➞ b Abnormality in release Abnormality in pressure- Disassemble pressure-releasing

of pressure releasing structure built portion carefully, then check

into pump and clean

Abnormality in pressure- Check limit switch at pressure-

detection equipment built detection portion

into pump

E ➞ c Abnormality in Abnormality in pressure- Check limit switch

pressure detection releasing structure built

into pump

Abnormality in pressure- Check limit switch at pressure-

detection equipment built detection portion

into pump

E ➞ 0 Empty tank Greasing frequency limit Add grease

has been reached

Grease added during Confirm that 0 flashes three

frequency count times on 7-segment LED by

pressing reset button on con-

troller for more than 5 seconds.

Loading...

Loading...