ENGLISH

23

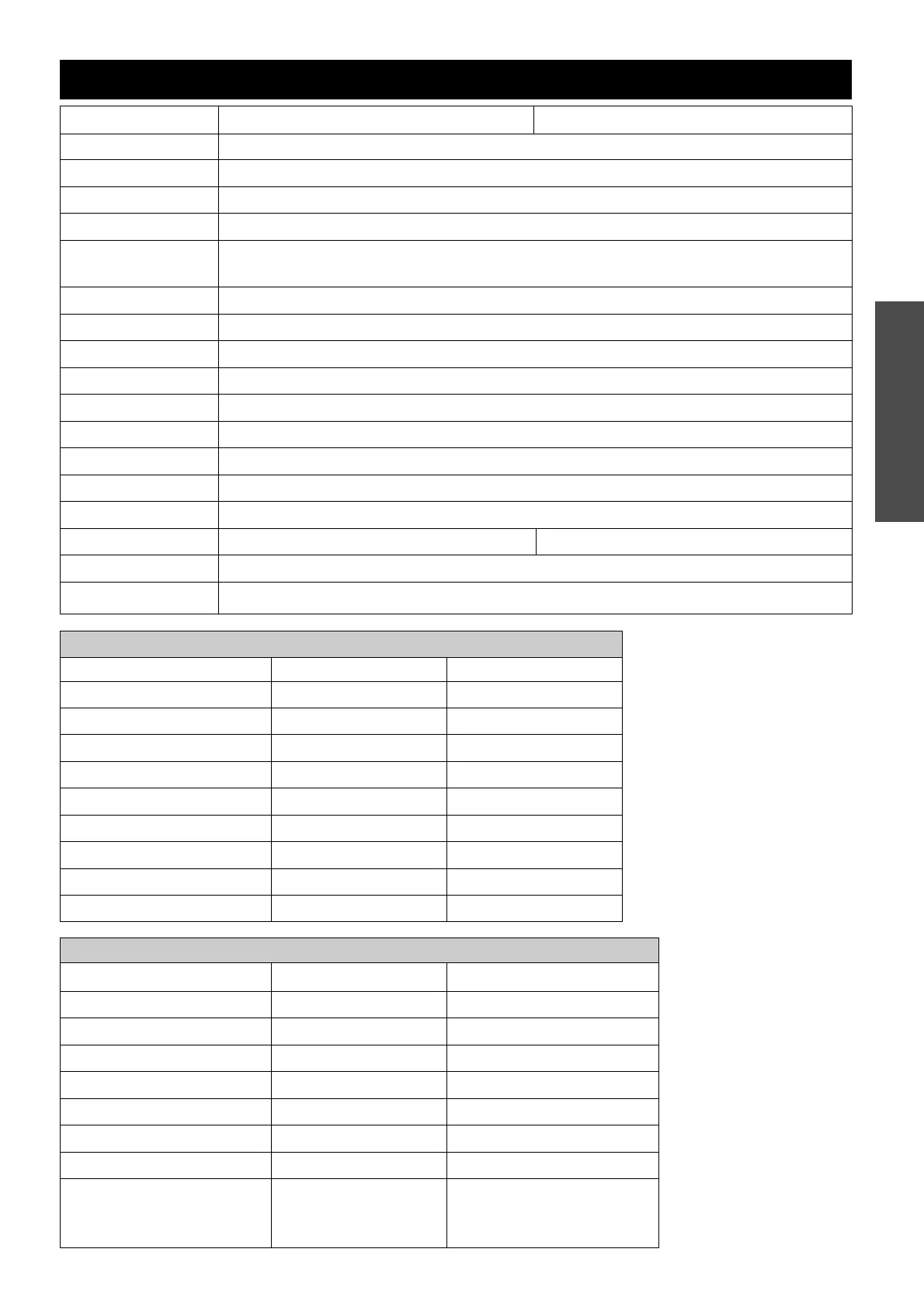

TECHNICAL DATA – ENGINE 50 LC 2002

Engine 50 SX PRO JUNIOR LC 50 SX PRO SENIOR LC

Design single cylinder 2-stroke engine, with reed valve inlet

Displacement 49.0 ccm

Bore/Stroke 39.5 / 40 mm

Fuel SUPER fuel, research octane no 95, mixed with 2-stroke oil

Oil/gasoline ratio 1 : 40 when using high grade 2-stroke oil (Shell Advance Racing X)

When in doupt, please contact your importer or use 1 : 33 mix ratio to be on the safe side

Lubrication mixture lubrication

Crankshaft bearing 2 grooved ball bearing

Connecting rod bearing

needle bearing

Piston pin bearing needle bearing

Piston rings 1 rectangular ring

Primary drive straight cut spur gears, 16 : 57 Z

Transmission oil 0.15-0,2 liter automatic gear oil Dexron II (Shell Donax TA)

Spark plug NGK BR 10 EG

Electrode gap 0.6 mm

Carbureto DellOrto PHVA 14 DS Dell’Orto PHBG 19 BS

Air filter wet foam type air filter insert

Cooling liquid 0,5 litres, 40% anti freeze, 60% water, at least -25 °C (-13 °F)

Primary gear nut M14x1,25 40 Nm (30 ft.lb)

Hexagon nut ignition rotor M10x1,25 20 Nm (15 ft.lb)

Nut of clutch hub M10x1,25

Loctite 243 + 35 Nm

(26 ft.lb)

Cylinder head screws M7 15 Nm (11 ft.lb)

Cylinder base nuts M8 18 Nm (13 ft.lb)

Allan head screw-Stator M5x25

Loctite 243 + 8

Nm (6 ft.lb)

Oil plug M16 5 Nm (4 ft.lb)

Oil drain plug M10 15 Nm (11 ft.lb)

Other screws engine M5 7 Nm (5 ft.lb)

M6 10 Nm (7 ft.lb)

M8 30 Nm (22 ft.lb)

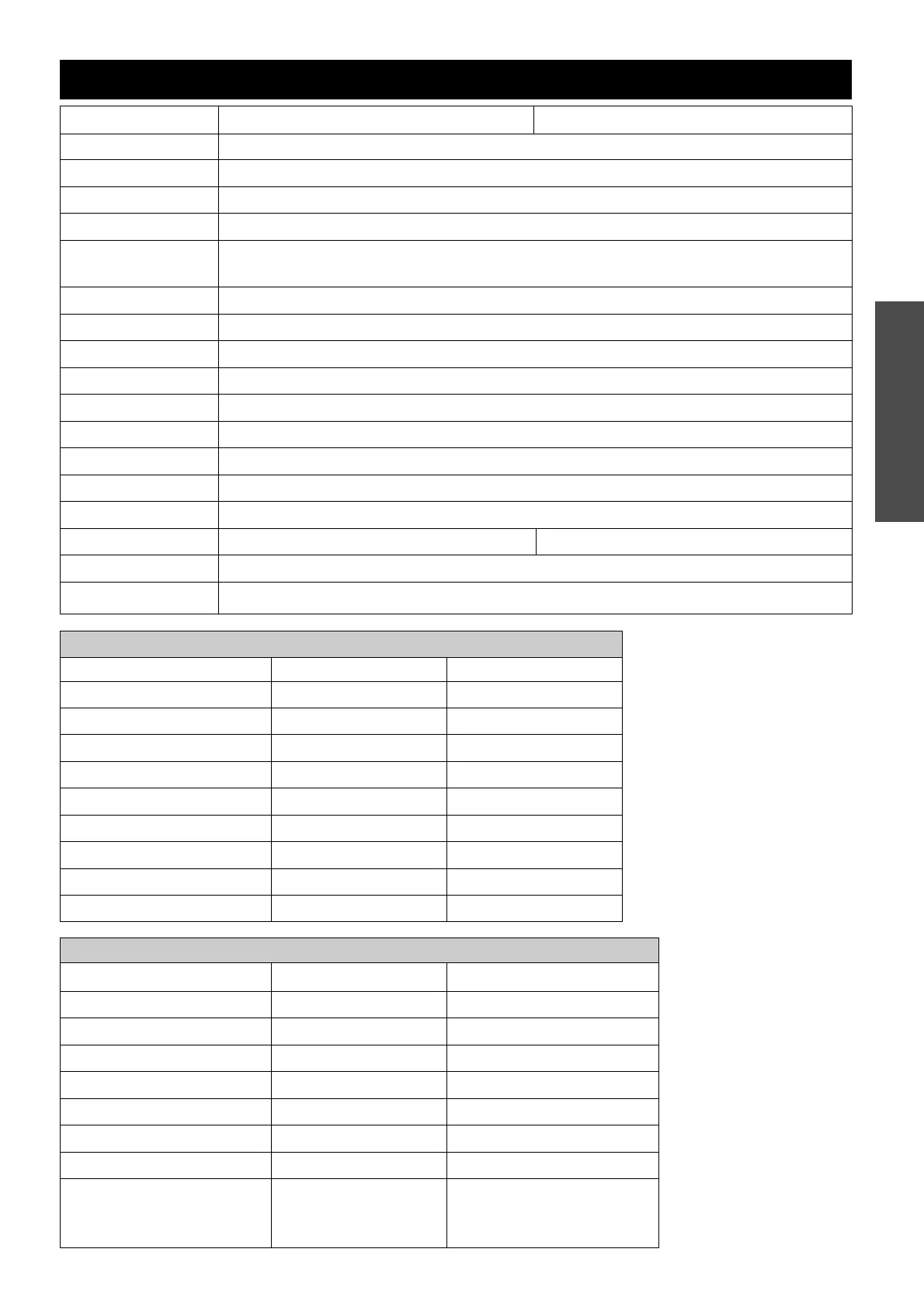

TIGHTENING TORQUES - ENGINE

Model 50 SX PRO JUNIOR LC 50 SX PRO SENIOR LC

Type Dell’Orto PHVA 14 DS Dell’Orto PHBG 19 BS

Main jet 80 85

Needle jet 211 FA 260 AU

Idling jet 45 48

Jet needle A10 W9

Needle position from top 3. 3.

Air/Mixture reg. screw open 3,5 3,0

Slide 40 60

Starting jet 60 60

BASIC CARBURETOR SETTING

Loading...

Loading...