97MAINTENANCE OF THE LOADER

DAILY CHECKS

1. Check all hardware daily before operation.

Tighten hardware to torque values as specified in the

"Tightening Torque Chart".

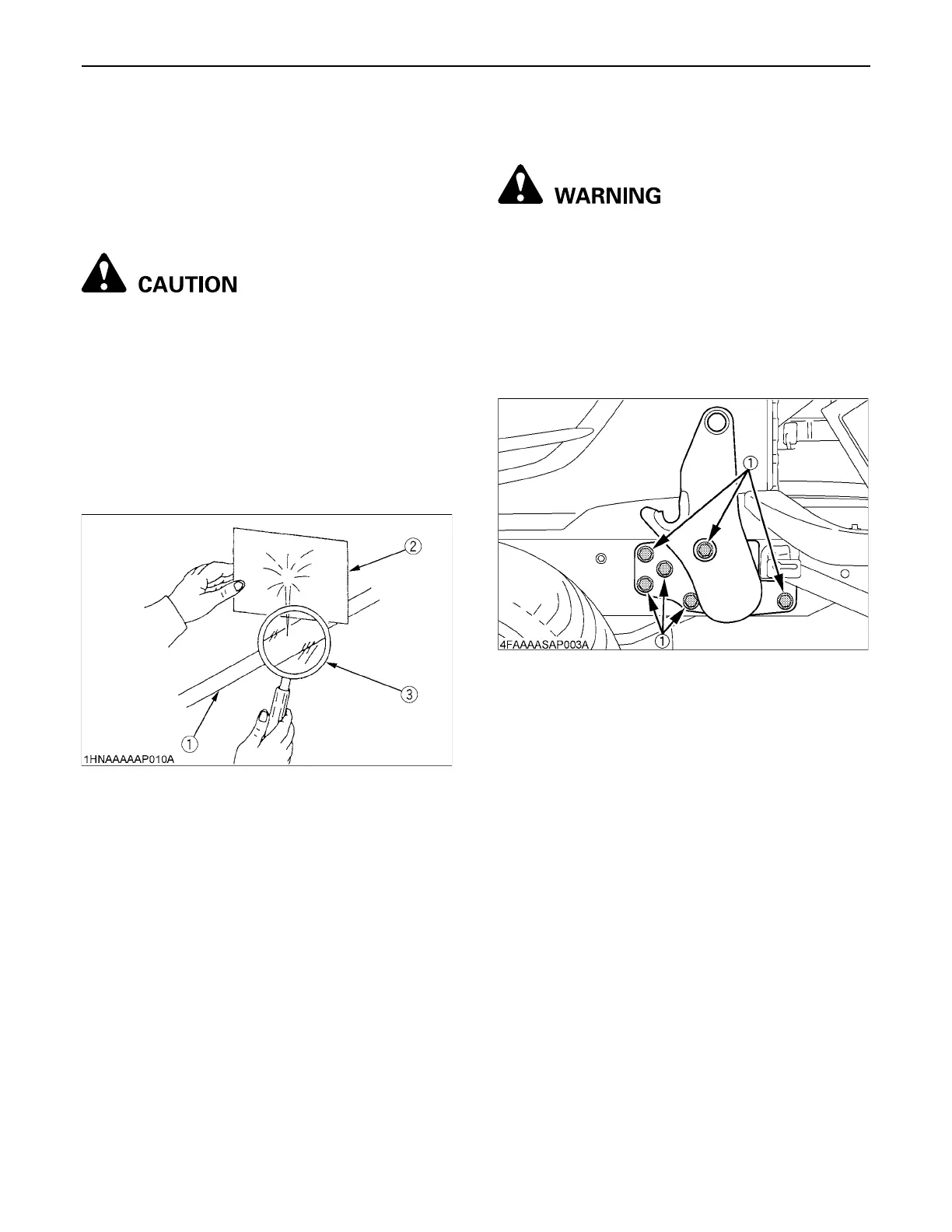

2. With the engine off and the bucket on the ground,

inspect all hoses for cuts or wear. Check for signs of

leaks and make sure all fittings are tight.

To avoid serious personal injury:

A Escaping hydraulic fluid under pressure can

have sufficient force to penetrate skin, causing

serious personal injury. Before disconnecting

lines, be sure to relieve all pressure.

Before applying pressure to system, be sure all

connections are tight and that lines, tubes, and

hoses are not damaged.

Fluid escaping from a very small hole can be

almost invisible. Use a piece of cardboard or

wood, rather than hands, to search for

suspected leaks.

If injured by escaping fluid, see a doctor at

once. Serious infection or allergic reaction will

develop if proper medical treatment is not

administered immediately.

A When removing the engine side covers, be

careful not to touch hot loader cylinders.

Allow all surfaces to cool before performing

maintenance.

EVERY 50 HOURS

BChecking main frame bolt and nut torque

To avoid serious injury:

A Never operate front loader with a loose main

frame.

A Any time bolts and nuts are loosened, retighten

to specified torque.

A Check all bolts and nuts frequently and keep

them tight.

Check main frame bolts and nuts regularly especially

when new. If they are loose, tighten them as follows.

(1) Hydraulic line

(2) Cardboard

(3) Magnifying glass

(1) Tightening torque : 147 N-m (15.0 kgf-m, 108 lbf-ft)