M.l

ENGINE

BODY

92.4mm STROKE SERIES

WSM,

01092

I

[3]

CRANKSHAFT

[4] PISTON

AND

PISTON RINGS

Y

A1 09FOO8

rr;i

CONNECTING

ROD

0

107FO 16

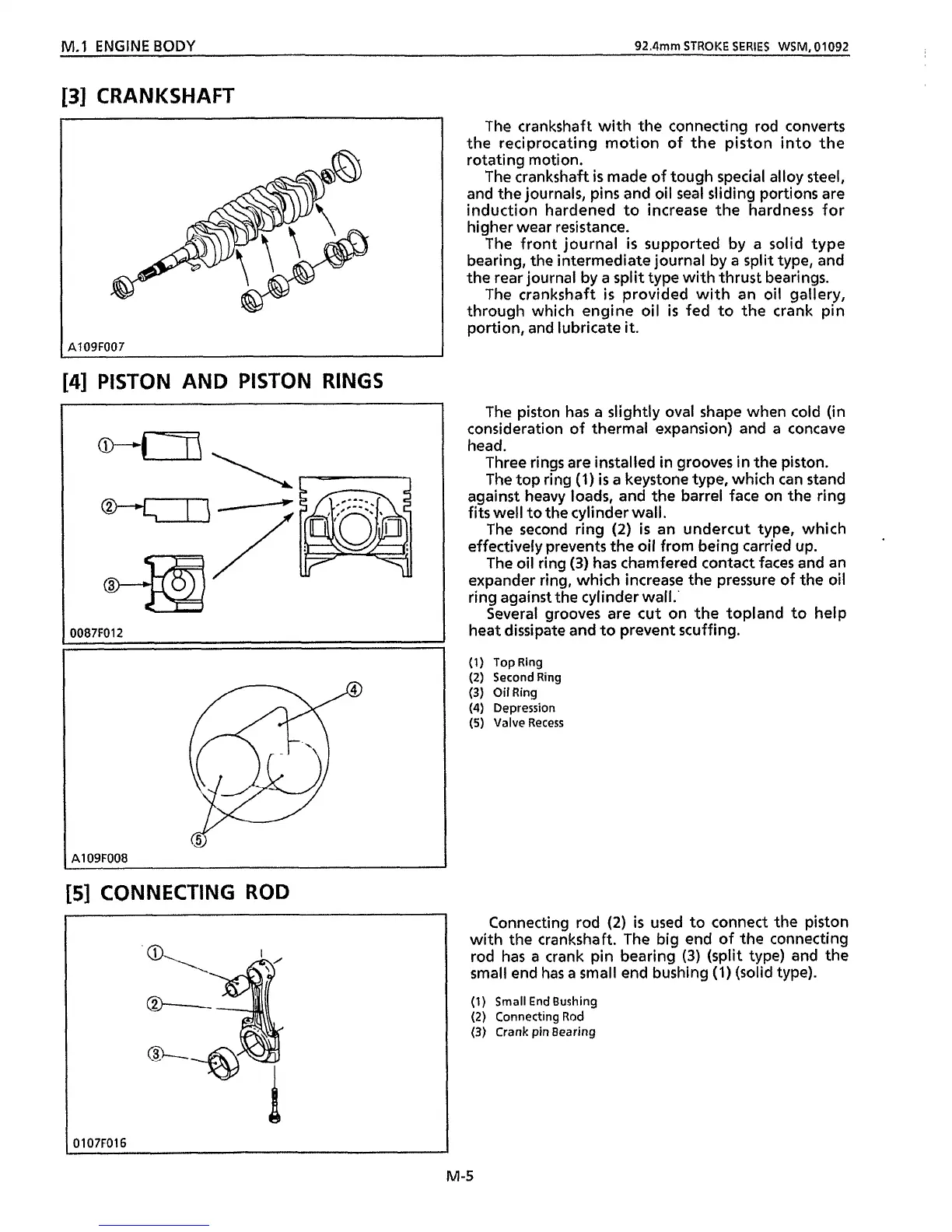

The crankshaft with the connecting rod converts

the reciprocating motion of the piston into the

rotating motion.

The crankshaft

is

made of tough special alloy

steel,

and the journals, pins and oil

seal

sliding portions are

induction hardened to increase the hardness for

higher wear resistance.

The front journal

is

supported by

a

solid type

bearing, the intermediate journal by

a

split type, and

the rear journal by

a

split type with thrust bearings.

The crankshaft

is

provided with an

oil

gallery,

through which engine oil

is

fed to

the

crank pin

portion, and lubricate

it.

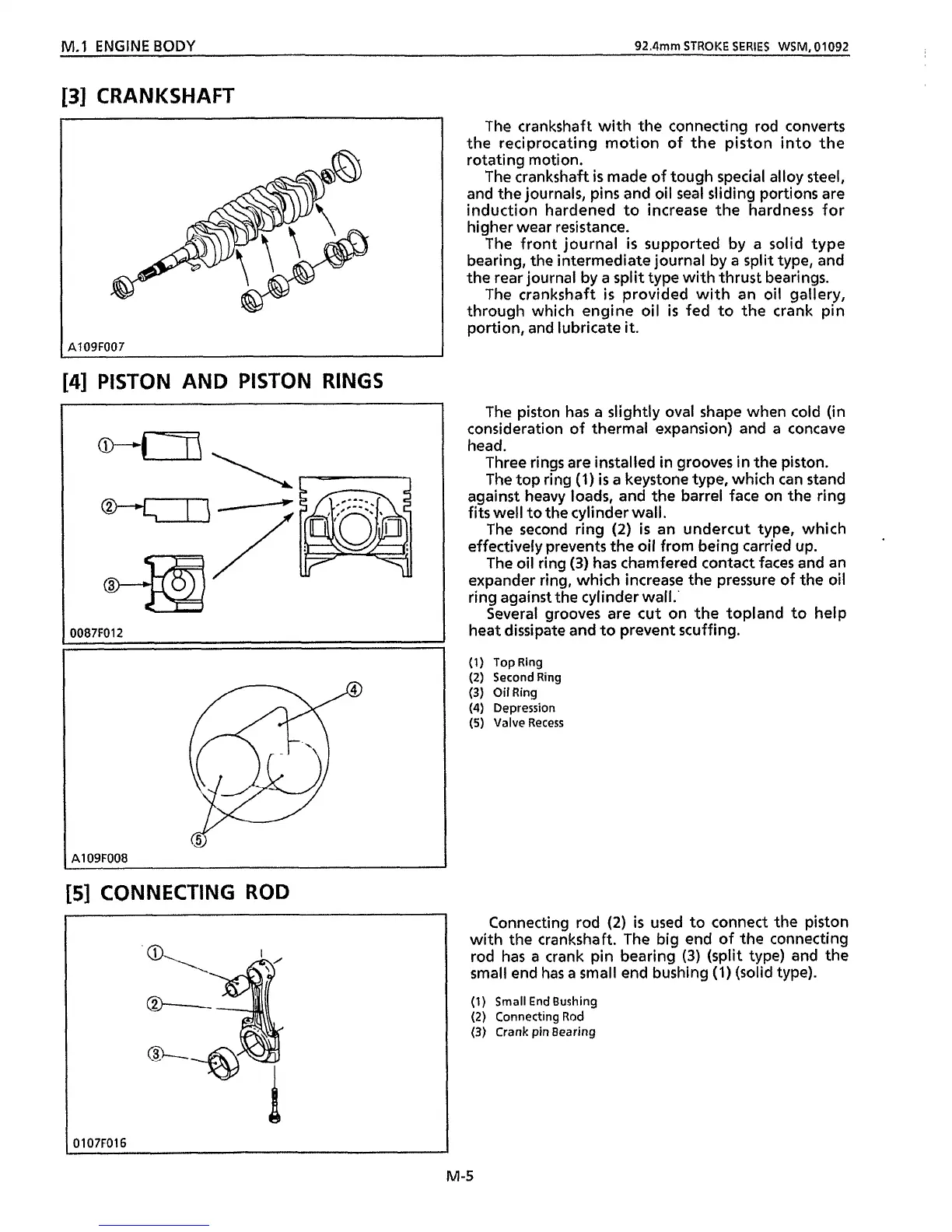

The piston has

a

slightly oval shape when cold (in

consideration of thermal expansion) and

a

concave

head.

Three rings are installed in grooves in the piston.

The top ring

(1)

is

a

keystone type, which can stand

against heavy loads, and the barrel face on the ring

fits well to the cylinder wall.

The second ring

(2)

is

an undercut type, which

effectively prevents the

oil

from being carried up.

The oil ring

(3)

has chamfered contact

faces

and an

expander ring, which increase the pressure of the oil

ring against the cylinder wall.'

Several grooves

are

cut

on

the topland to help

heat

dissipate and to prevent scuffing.

(1)

TopRing

(2)

Second Ring

(3)

OilRing

(4) Depression

(5)

Valve Recess

Connecting rod

(2)

is

used to connect the piston

with the crankshaft. The big end of the connecting

rod has

a

crank pin bearing

(3)

(split type) and the

small end has

a

small end bushing

(1)

(solid type).

(1)

Small

End

Bushing

(2) Connecting Rod

(3)

Crank

pin Bearing

N-5

Loading...

Loading...