61TIRES, WHEELS AND BALLAST

WHEEL ADJUSTMENT

To avoid personal injury or death:

A When working on slopes or when working with

trailer, set the wheel tread as wide as practical

for maximum stability.

A Support tractor securely on stands before

removing a wheel.

A Do not work under any hydraulically supported

devices. They can settle, suddenly leak down,

or be accidentally lowered. If necessary to work

under tractor or any machine elements for

servicing or adjustment, securely support them

with stands or suitable blocking beforehand.

A Never operate tractor with a loose rim, wheel,

or axle.

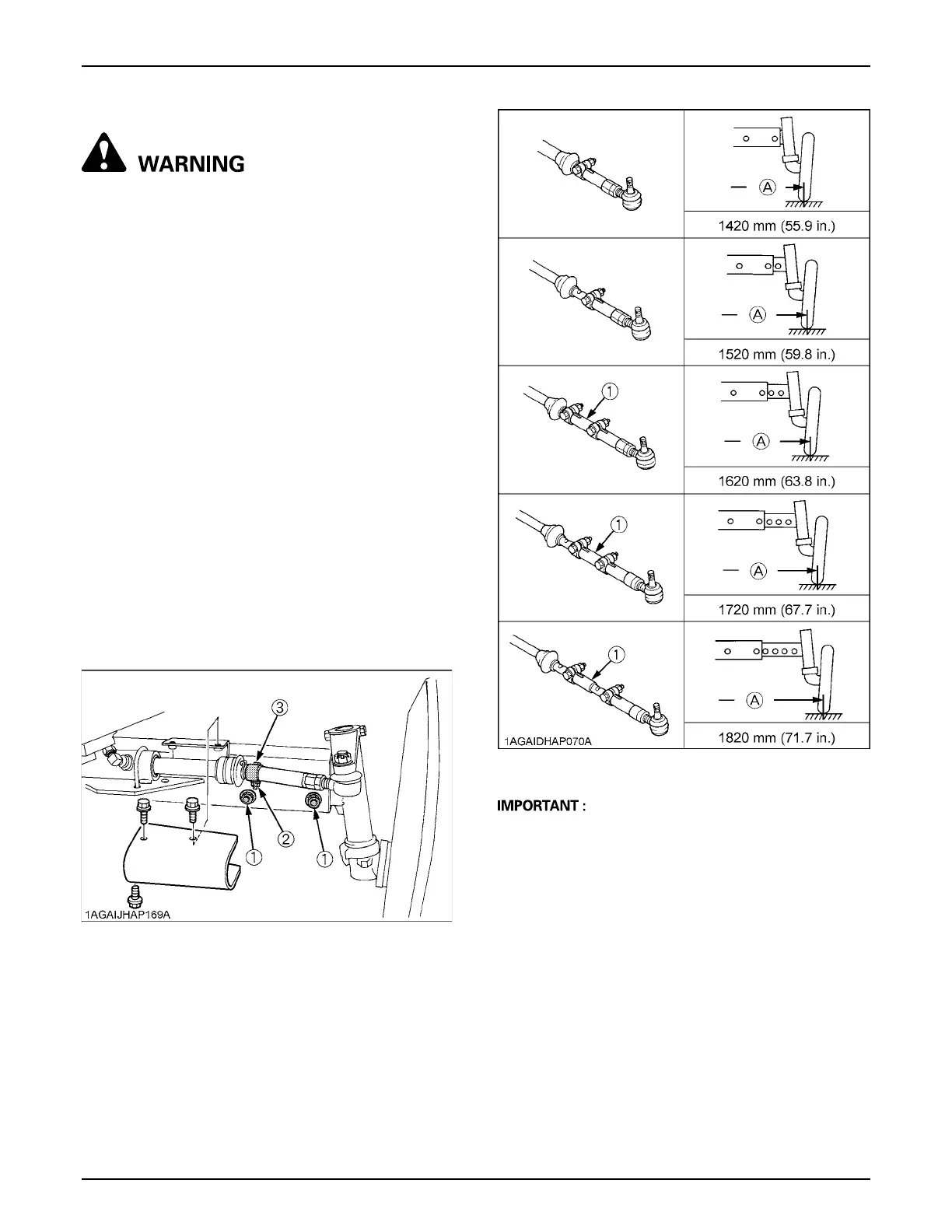

BFront Wheels (with 2-wheel drive)

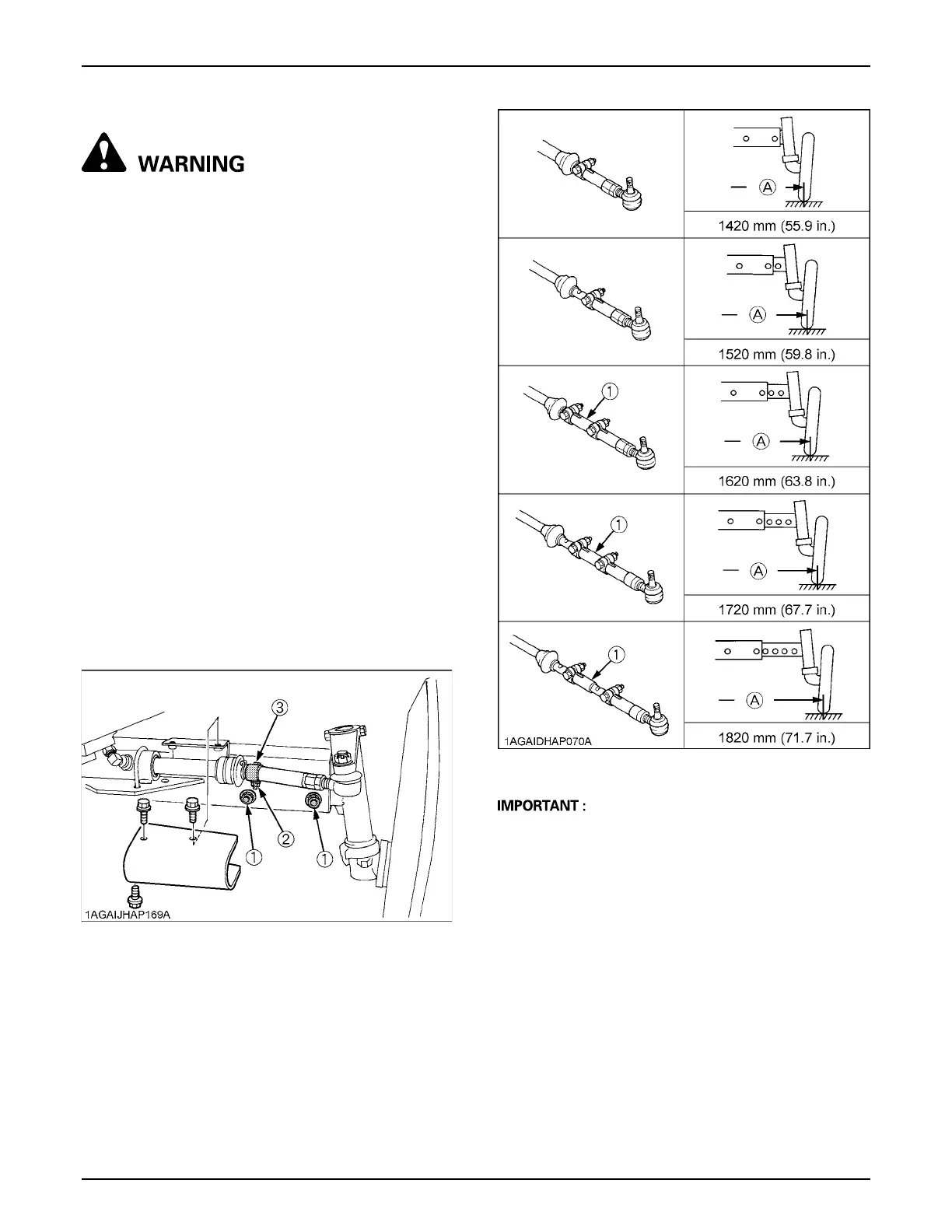

Front tread width can be adjusted as shown with the

standard equipped tires.

To change the tread width

1. Remove the front axle mounting bolts and the tie-rod

mounting bolts.

2. Move the front axles (right and left) to the desired

position, and tighten the bolts.

3. Adjust the toe-in: [ 1 to 5 mm (0.04 to 0.2 in.)]

(See "Adjusting Toe-in" in "EVERY 200 HOURS" in

"PERIODIC SERVICE" section.)

A The front tread width for the front loader application on

2WD models should not be greater than 1420 mm

(55.9 in.).

(1) Front axle mounting bolt

124 to 147 N-m (12.6 to 15 kgf-m) [91.5 to 108.9 ft-lbs.]

(2) Tie-rod mounting bolt

61 to 71 N-m (6.2 to 7.2 kgf-m) [44.8 to 52.1 ft-lbs.]

(3) Tie rod clamp

(1) Extension1 (A) "TREAD"

Loading...

Loading...