38

6 O

2

Trim

6.5.2 O

2

Monitoring Band

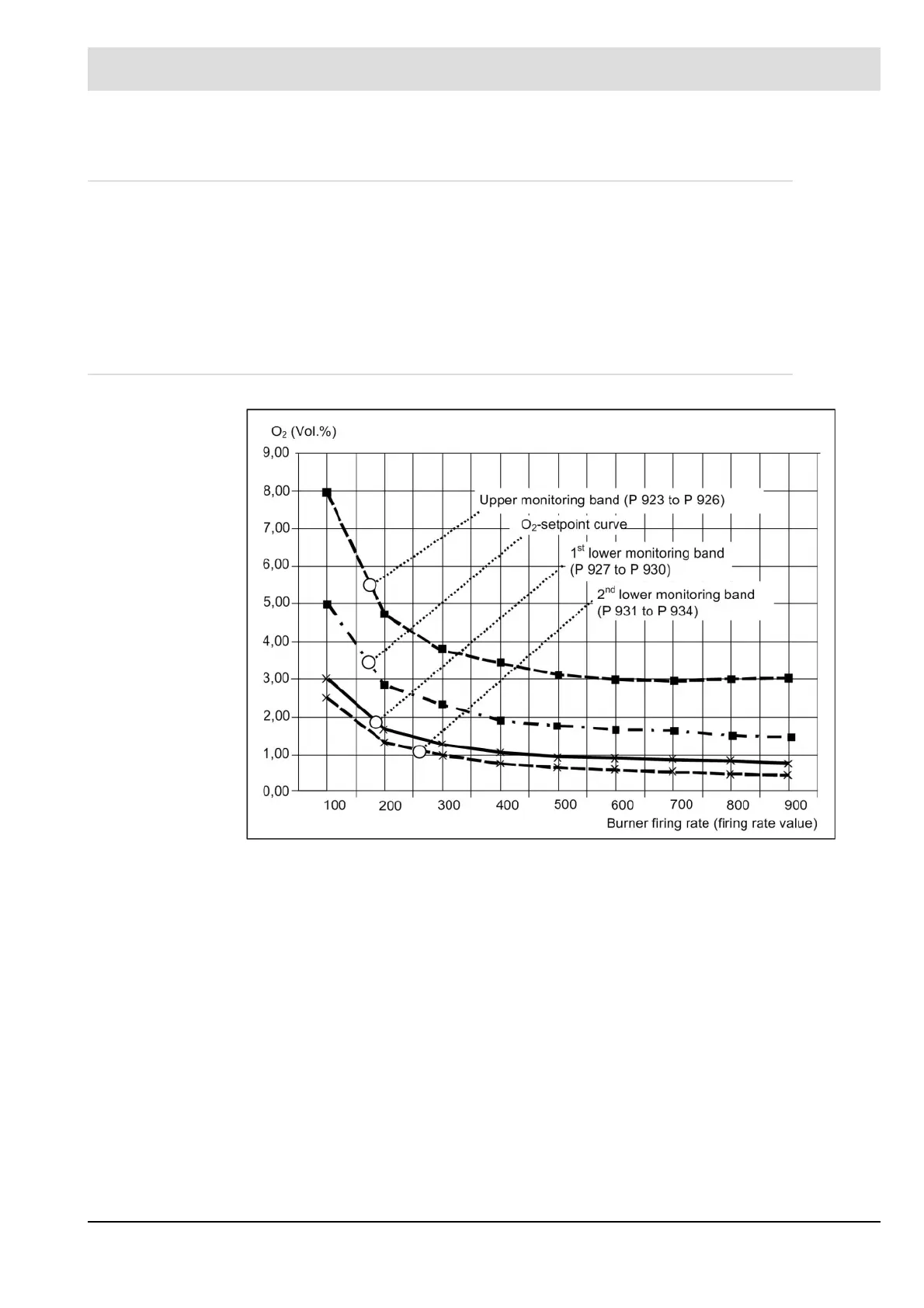

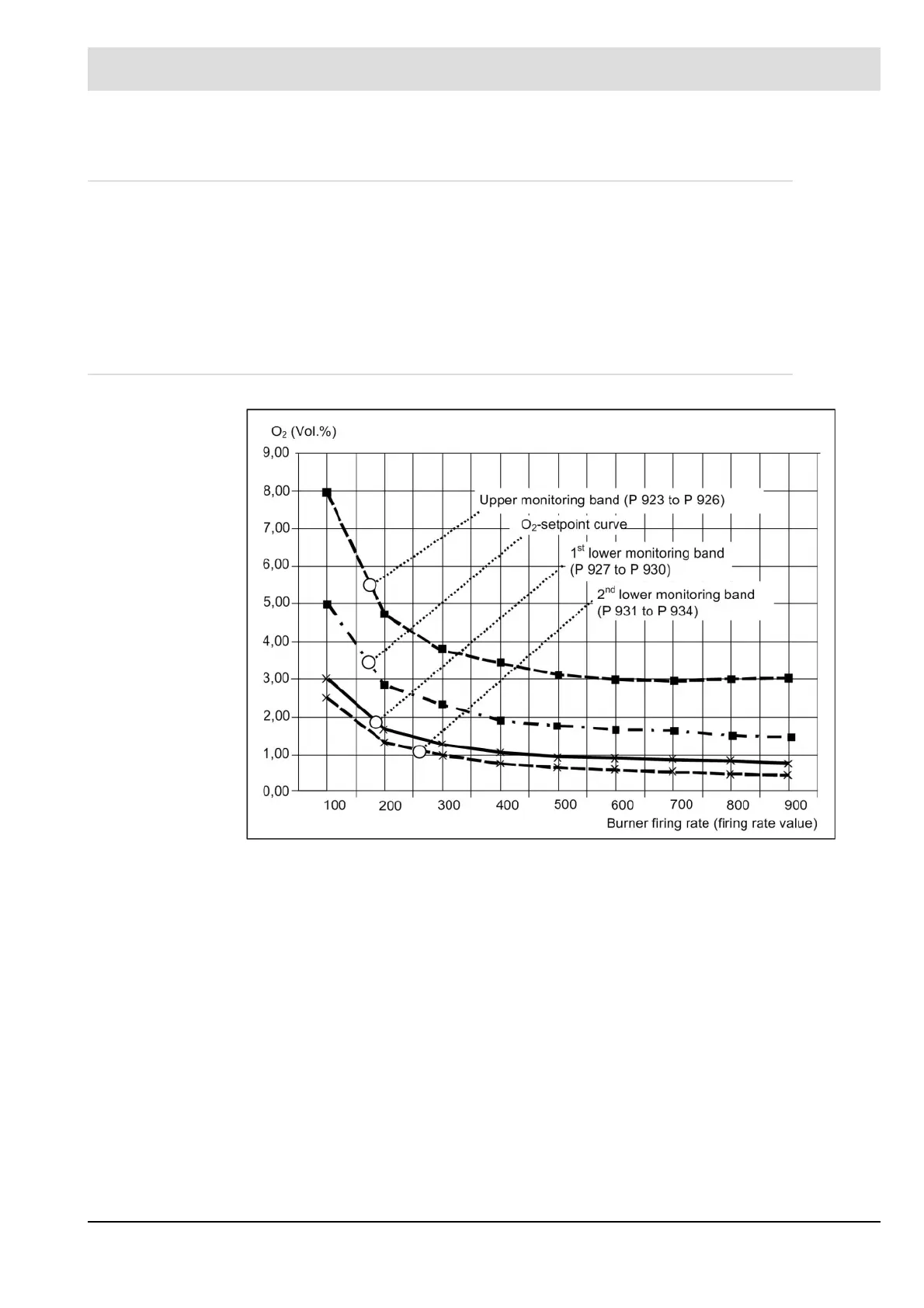

During burner operation, the actual O

2

value is continuously monitored for one maximum and

two minimum permissible values. These ranges are located around the O

2

setpoint as a func-

tion of firing rate. If the actual values stay outside these bands for a defined period, the control

system is deactivated and a “Fault” warning is output.

Thereafter, the control unit’s output (correction input) corresponds to “Base value without con-

trol” or “Base value with air deficiency”.

6.5.3 O

2

Limit Curve

You can set the monitoring bands’ parameters for 2 fuels, oil/gas, as a function of fuel. The

permitted deviation is calculated as a percentage of the setpoint. You can specify two separate

percentage values for base firing rate and full firing rate. The section between is interpolated

linearly.

Monitoring/shutdown times:

1

st

monitoring band: 120 seconds; active after “Control on”.

2

nd

monitoring band: 30 seconds; active after “Burner on”.

Factory setting

1

st

monitoring band, upward direction

– Base firing rate (parameters 923 / 925) 60%

– Full firing rate (parameters 924 / 926) 100%

1

st

monitoring band, downward direction

– Base firing rate (parameters 927 / 929) 40%

– Full firing rate (parameters 928 / 930) 50%

Loading...

Loading...