Page 22

G−High Altitude Derate

NOTE−In Canada, certification for installation at alti-

tudes over 4500 ft. (1372m) above sea level is the juris-

diction of the local authorities.

80MGF−1 through −8 Models

This unit does not require gas pressure adjustment, or

pressure switch change when operating at elevations of 0

to 7500 ft. (0 to 2248m). Check gas line pressure with unit

firing. The minimum pressure as shown on the nameplate

for natural and propane gases must be maintained. No ori-

fice change is required.

NOTE−This is the only permissible field derate for this

appliance.

80MGF−9, −10 and −11 Models

Table 14 shows manifold pressure settings for installations

at different altitudes. Refer to table 15 for pressure switch

replacement for models at elevations of 4500 feet (1372m)

and greater.

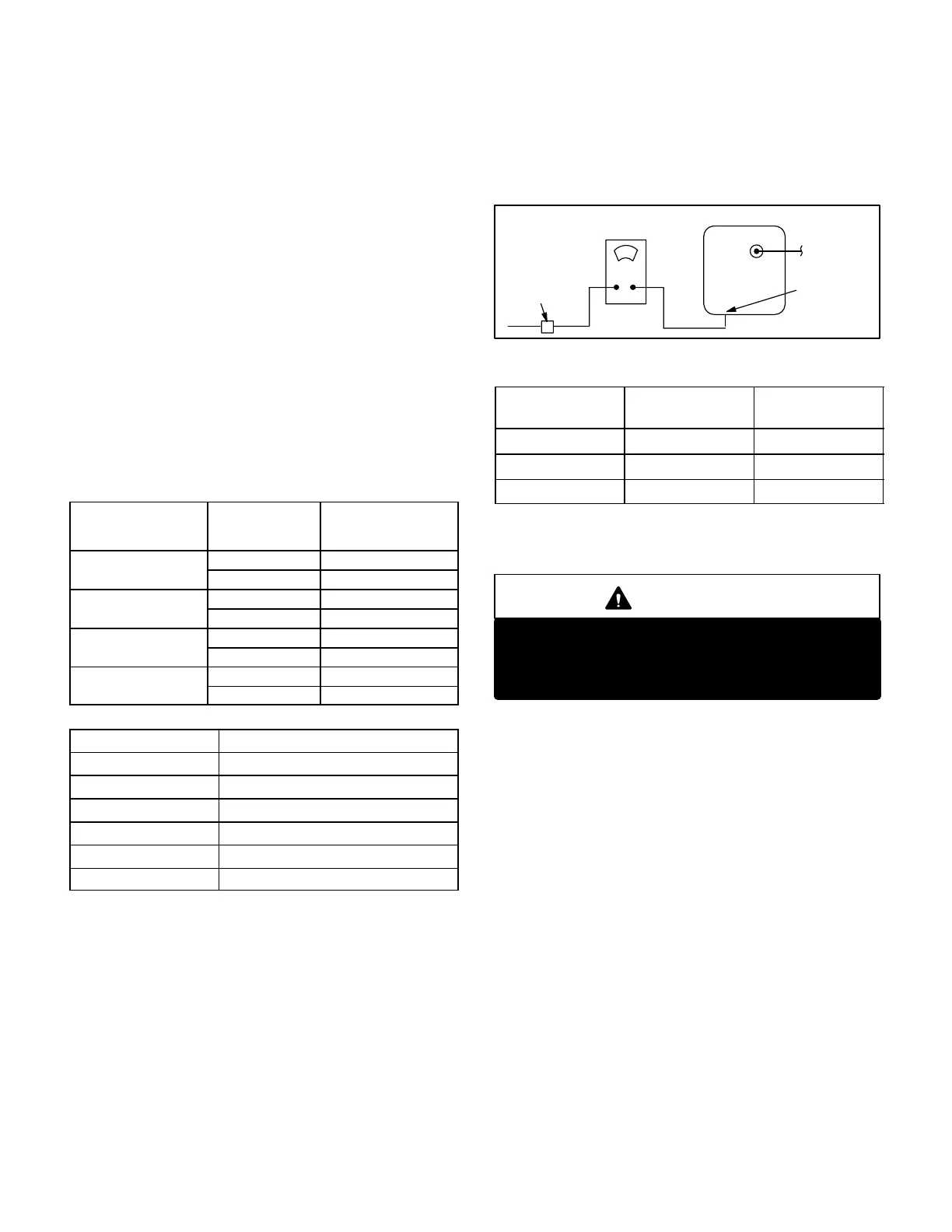

TABLE 14

ALTITUDE

feet (m)

GAS FUEL

MANIFOLD

PRESSURE

in. W.C. (kPa)

0 − 4500

Natural 3.5 (0.87)

(0 − 1372)

Propane/LP 9.5 (2.36)

4500 − 5500

Natural 3.4 (0.86)

(1372 − 1676)

Propane/LP 9.2 (2.29)

5500 − 6500

Natural 3.3 (0.82)

(1676 − 1981)

Propane/LP 8.9 (2.21)

6500 − 7500

Natural 3.2 (0.80)

(1372 − 2286)

Propane/LP 8.6 (2.14)

TABLE 15

Unit Model Pressure Switch Part Number

80MGF−45 No Change

80MGF−60 No Change

80MGF−75 88J8001

80MGF−100 18L2401

80MGF−120 18L2401

80MGF−140 No Change

H−Flame Signal

A microamp DC meter is needed to check the flame signal

on the primary ignition control.

Flame (microamp) signal is an electrical current which

passes from the furnace control through the sensor elec-

trode during unit operation. Current passes from the sen-

sor through the flame to ground to complete a safety cir-

cuit.

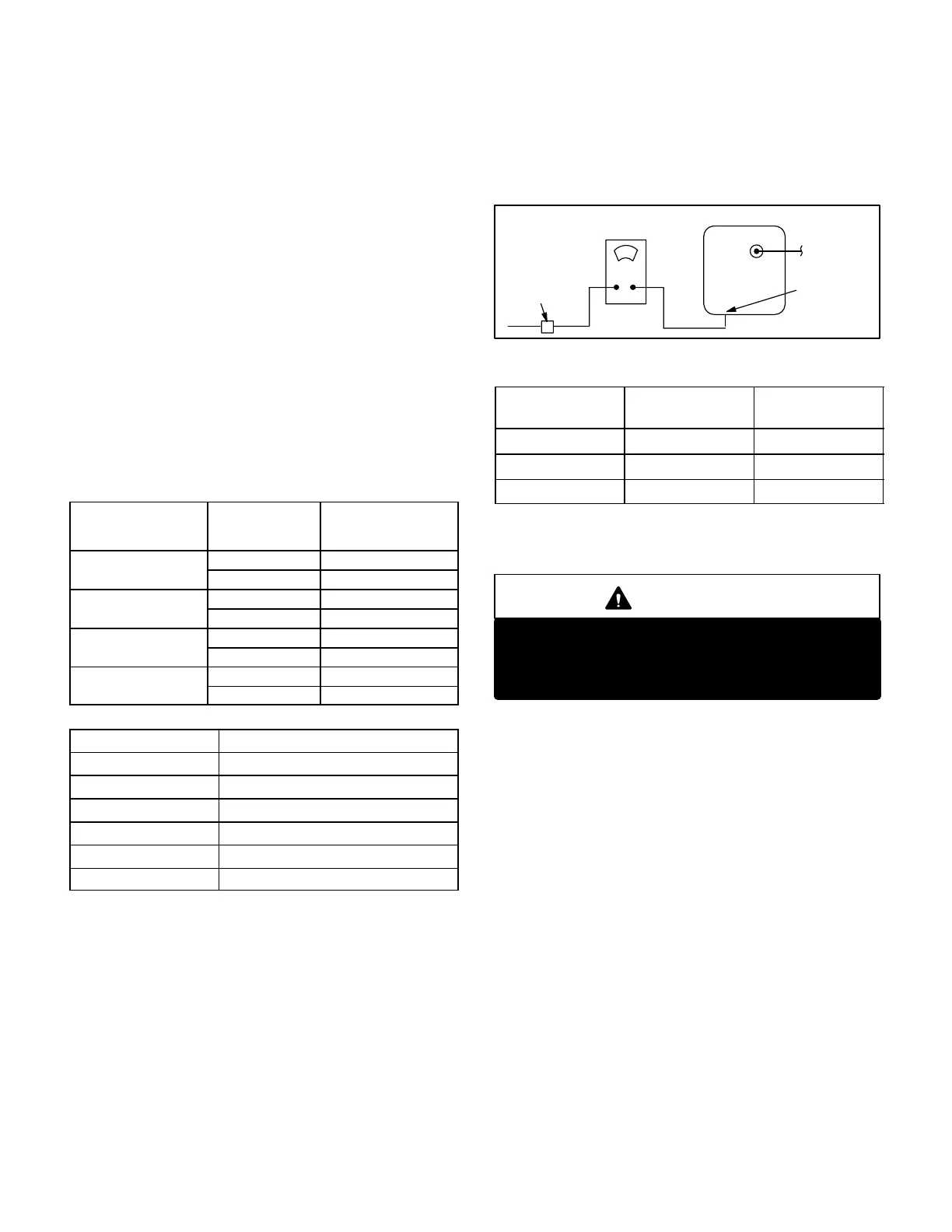

To Measure Flame Signal:

1− Place meter in series between furnace control and

sensor wire. Connect the positive (+) lead of meter to

the ignition control sensor connection and the nega-

tive (−) lead of the meter to the sensor wire. See figure

23.

2− Set thermostat for a heating demand and check flame

signal with unit operating. See table 16 for microamp

reading for the various control boards used.

FLAME SIGNAL TEST

FIGURE 23

IGNITION

CON-

TROL

SENSE"

TERMINAL

SENSOR

WIRE

D.C. MICROAMP

METER

FLAME

SENSOR

TABLE 16

CONTROL

MICROAMP

SIGNAL

DROP OUT

SIGNAL

Ram 1.0 to 5.0 t1.0

EGC 1.0 to 5.0 v.45

SureLight w.70 v.15

Flame signal may rise above 5 microamps for the first few

seconds after ignition then level off within the range.

WARNING

Fire and explosion hazard.

These instructions MUST be followed exactly.

Can cause a fire or explosion resulting in property

damage, personal injury or loss of life.

V−TYPICAL OPERATING CHARACTERISTICS

A−Blower Operation and Adjustment

NOTE− The following is a generalized procedure and

does not apply to all thermostat controls.

1− Blower operation is dependent on thermostat control

system.

2− Generally, blower operation is set at thermostat sub-

base fan switch. With fan switch in ON position, blower

operates continuously on heating speed. With fan

switch in AUTO position, blower cycles with demand or

runs continuously while heating or cooling circuit cycles.

3− Depending on the type of indoor thermostat, blower

and entire unit will be off when the system switch is in

OFF position.

B−Temperature Rise

Temperature rise for 80MGF units depends on unit input,

blower speed, blower horsepower and static pressure as

marked on the unit rating plate. The blower speed must be

set for unit operation within the range of AIR TEMP. RISE

°F" listed on the unit rating plate.

Loading...

Loading...