Page 12

506044−01 06/08

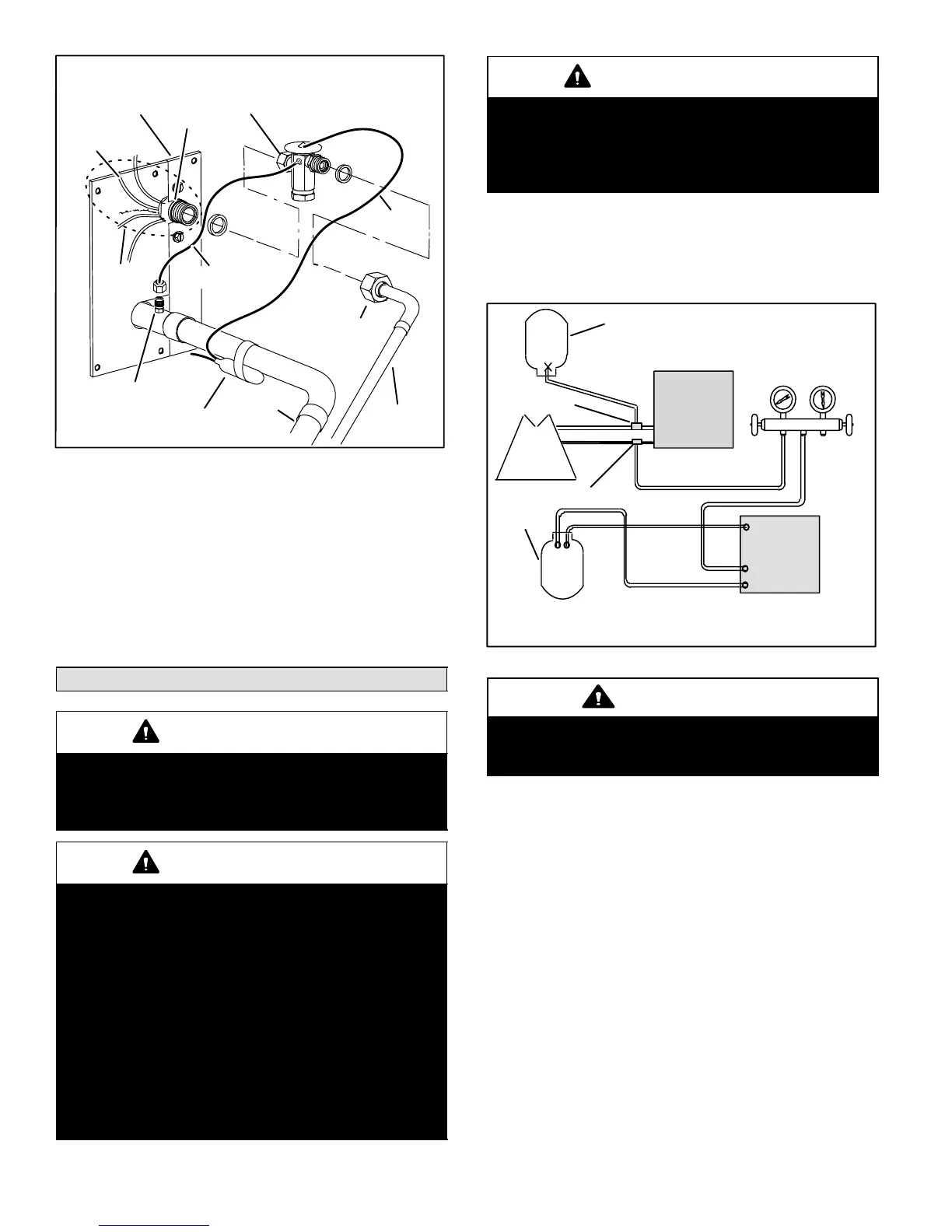

TWO PIECE

PATCH PLATE

(UNCASED COIL

ONLY)

SUCTION

LINE

DISTRIBUTOR

ASSEMBLY

DISTRIBUTOR

TUBES

LIQUID

LINE

MALE EQUALIZER

LINE FITTING

SENSING

LINE

EQUALIZER

LINE

TXV

TEFLON

RING

(Uncased Coil Shown)

STUB END

TEFLON

RING

SENSING

BULB

LIQUID LINE

ORIFICE

HOUSING

LIQUID LINE ASSEMBLY

WITH BRASS NUT

Figure 23. Typical TXV Removal

6. Disconnect the TXV from the liquid line orifice housing.

Take care not to twist or damage distributor tubes

during this process.

7. Remove and discard TXV and the two Teflon rings as

illustrated in figure 23.

8. Use a field−provided fitting to temporary reconnect the

liquid line to the indoor unit’s liquid line orifice housing.

Flushing the System

IMPORTANT

The line set and indoor unit coil must be flushed

with at least the same amount of clean refrigerant

that previously charged the system. Check the

charge in the flushing cylinder before proceeding.

IMPORTANT

If this unit is being matched with an approved line

set or indoor unit coil which was previously

charged with mineral oil, or if it is being matched

with a coil which was manufactured before

January of 1999, the coil and line set must be

flushed prior to installation. Take care to empty all

existing traps. Polyol ester (POE) oils are used in

Lennox units charged with HFC−410A refrigerant.

Residual mineral oil can act as an insulator,

preventing proper heat transfer. It can also clog

the expansion device, and reduce the system

performance and capacity.

Failure to properly flush the system per the

instructions below will void the warranty.

IMPORTANT

The Environmental Protection Agency (EPA)

prohibits the intentional venting of HFC refrigerants

during maintenance, service, repair and disposal of

appliance. Approved methods of recovery,

recycling or reclaiming must be followed.

If the original system used:

S HCFC−22 refrigerant, then flush the system using the

procedure provided in this section.

S HFC−410A refrigerant, then proceed to Installing New

Refrigerant Metering Device.

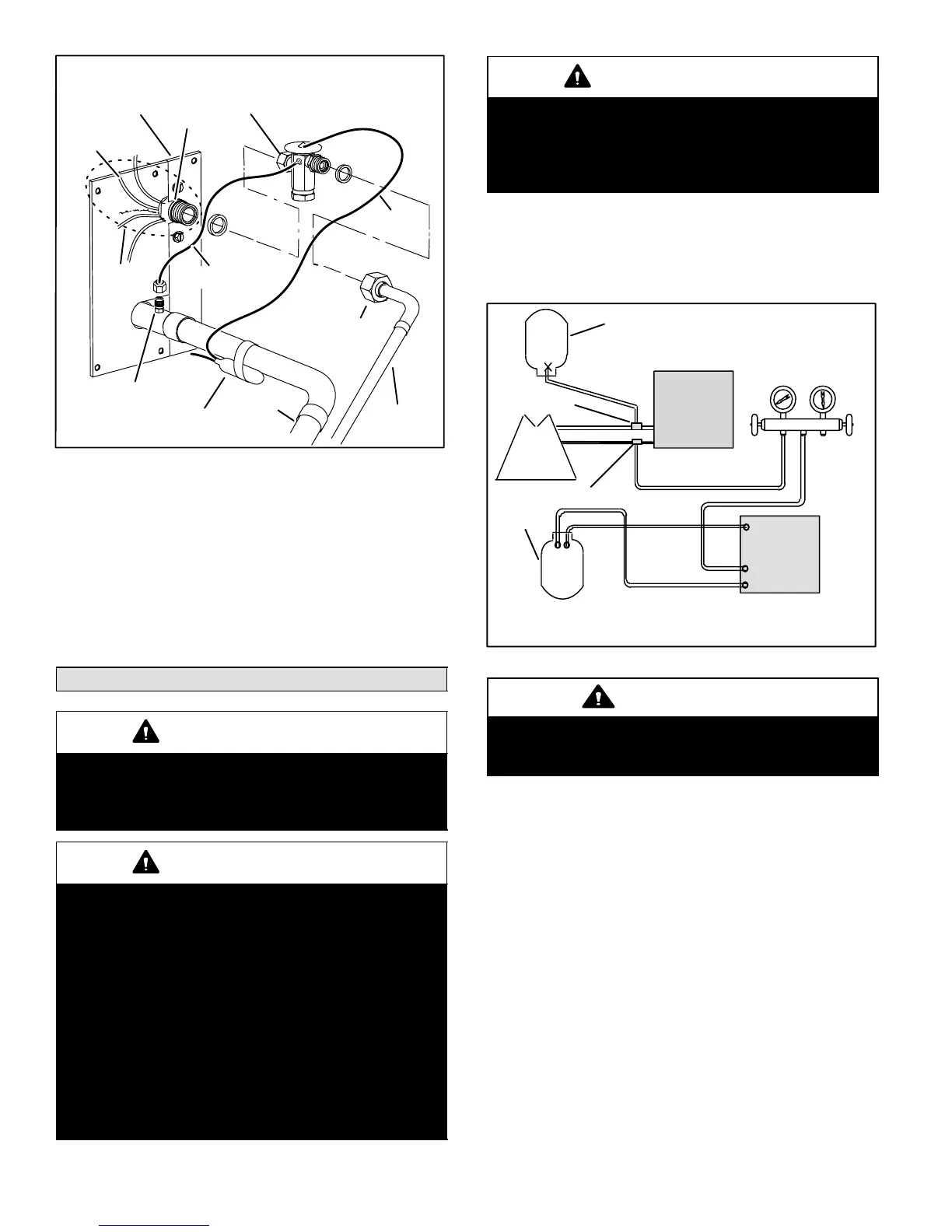

LOW

PRESSURE

HIGH

PRESSURE

EXISTING

INDOOR

UNIT

GAUGE

MANIFOLD

INVERTED HCFC−22 CYLINDER

CONTAINS CLEAN HCFC−22 TO

BE USED FOR FLUSHING.

LIQUID LINE SERVICE VALVE

INLET

DISCHARGE

TANK

RETURN

CLOSED

OPENED

RECOVERY

CYLINDER

NOTE − The inverted HCFC−22 cylinder must contain at least the same

amount of refrigerant as was recovered from the existing system.

RECOVERY MACHINE

NEW

OUTDOOR

UNIT

SUCTION LINE

SERVICE VALVE

SUCTION

LIQUID

Figure 24. Typical Flushing Connection

CAUTION

This procedure should not be performed on

systems which contain contaminants (Example:

compressor burn out).

REQUIRED EQUIPMENT

Equipment required to flush the existing line set and indoor

unit coil:

S Two clean HCFC−22 recovery bottles,

S Oilless recovery machine with pump-down feature,

S Two gauge sets (one for HCFC−22; one for

HFC−410A).

PROCEDURE

1. Connect the following:

S HCFC−22 cylinder with clean refrigerant to the

suction service valve,

S HCFC−22 gauge set to the liquid line valve,

S Recovery machine with an empty recovery tank to

the gauge set.

2. Set the recovery machine for liquid recovery and start

the recovery machine. Open the gauge set valves to

allow the recovery machine to pull a vacuum on the

existing system line set and indoor unit coil.

Loading...

Loading...