Page 19

XC15 SERIES

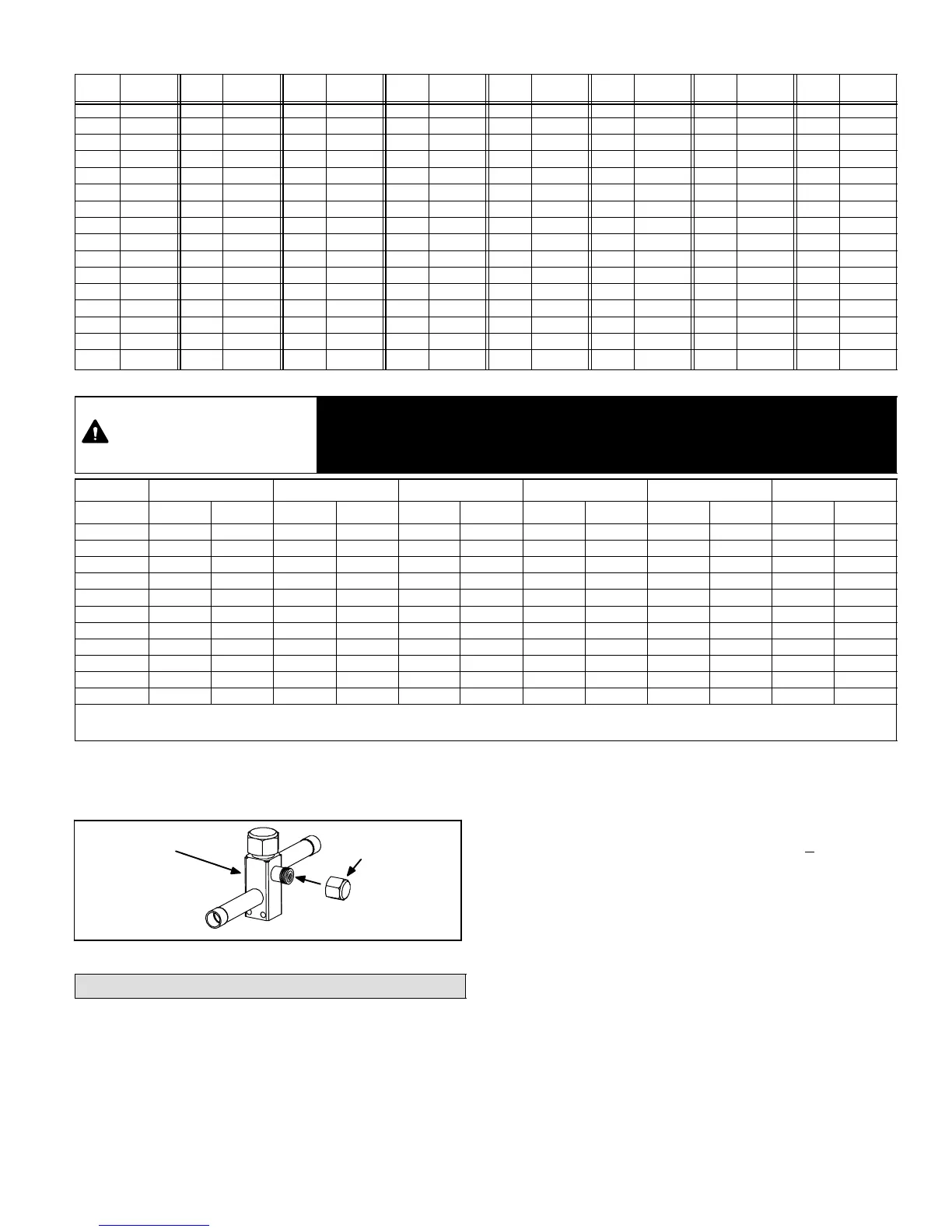

Table 4. HFC−410A Temperature (°F) − Pressure (Psig)

°F Psig °F Psig °F Psig °F Psig °F Psig °F Psig °F Psig °F Psig

32 100.8 48 137.1 63 178.5 79 231.6 94 290.8 110 365.0

125 445.9

141 545.6

33 102.9 49 139.6 64 181.6 80 235.3 95 295.1 111 370.0 126 451.8 142 552.3

34 105.0 50 142.2 65 184.3 81 239.0 96 299.4 112 375.1 127 457.6 143 559.1

35 107.1 51 144.8 66 187.7 82 242.7 97 303.8 113 380.2 128 463.5 144 565.9

36 109.2 52 147.4 67 190.9 83 246.5 98 308.2 114 385.4 129 469.5 145 572.8

37 111.4 53 150.1 68 194.1 84 250.3 99 312.7 115 390.7 130 475.6 146 579.8

38 113.6 54 152.8 69 197.3 85 254.1 100 317.2 116 396.0 131 481.6 147 586.8

39 115.8 55 155.5 70 200.6 86 258.0 101 321.8 117 401.3 132 487.8 148 593.8

40 118.0 56 158.2 71 203.9 87 262.0 102 326.4 118 406.7 133 494.0 149 601.0

41 120.3 57 161.0 72 207.2 88 266.0 103 331.0 119 412.2 134 500.2 150 608.1

42 122.6 58 163.9 73 210.6 89 270.0 104 335.7 120 417.7 135 506.5 151 615.4

43 125.0 59 166.7 74 214.0 90 274.1 105 340.5 121 423.2 136 512.9 152 622.7

44 127.3 60 169.6 75 217.4 91 278.2 106 345.3 122 428.8 137 519.3 153 630.1

45 129.7 61 172.6 76 220.9 92 282.3 107 350.1 123 434.5 138 525.8 154 637.5

46 132.2 62 175.4 77 224.4 93 286.5 108 355.0 124 440.2 139 532.4 155 645.0

47 134.6 78 228.0 109 360.0 140 539.0

Table 5. Normal Operating Pressures (Liquid +10 and Suction +5 psig)

IMPORTANT

Use this table to perform maintenance checks; it is not a procedure for charg-

ing the system. Minor variations in these pressures may be due to differences

in installations. Significant deviations could mean that the system is not prop-

erly charged or that a problem exists with some component in the system.

Model −024 −030 −036 −042 −048 −060

°F (°C)** Liquid Suction Liquid Suction Liquid Suction Liquid Suction Liquid Suction Liquid Suction

65 (18.3) 238 139 246 138 251 133 261 144 224 129 242 131

70 (21.1) 256 139 265 139 270 134 281 145 241 130 262 132

75 (23.9) 275 140 287 140 291 134 303 146 259 131 282 134

80 (26.7) 296 141 307 141 312 134 326 147 279 133 303 135

85 (29.4) 319 142 330 142 335 136 350 148 301 134 326 136

90 (32.2) 342 142 354 143 359 137 376 149 323 135 349 137

95 (35.0) 366 143 379 144 384 138 402 150 347 137 372 138

100 (37.8) 392 144 404 144 411 140 430 151 372 138 397 140

105 (40.6) 418 146 432 145 438 141 459 152 397 140 422 141

110 (43.3) 448 146 461 147 468 143 490 153 422 141 448 143

115 (46.1) 480 147 491 148 501 144 525 154 449 143 475 146

* These are typical pressures only. Indoor match up, indoor air quality, and indoor load will cause the pressures to vary.

** Temperature of air entering outdoor coil.

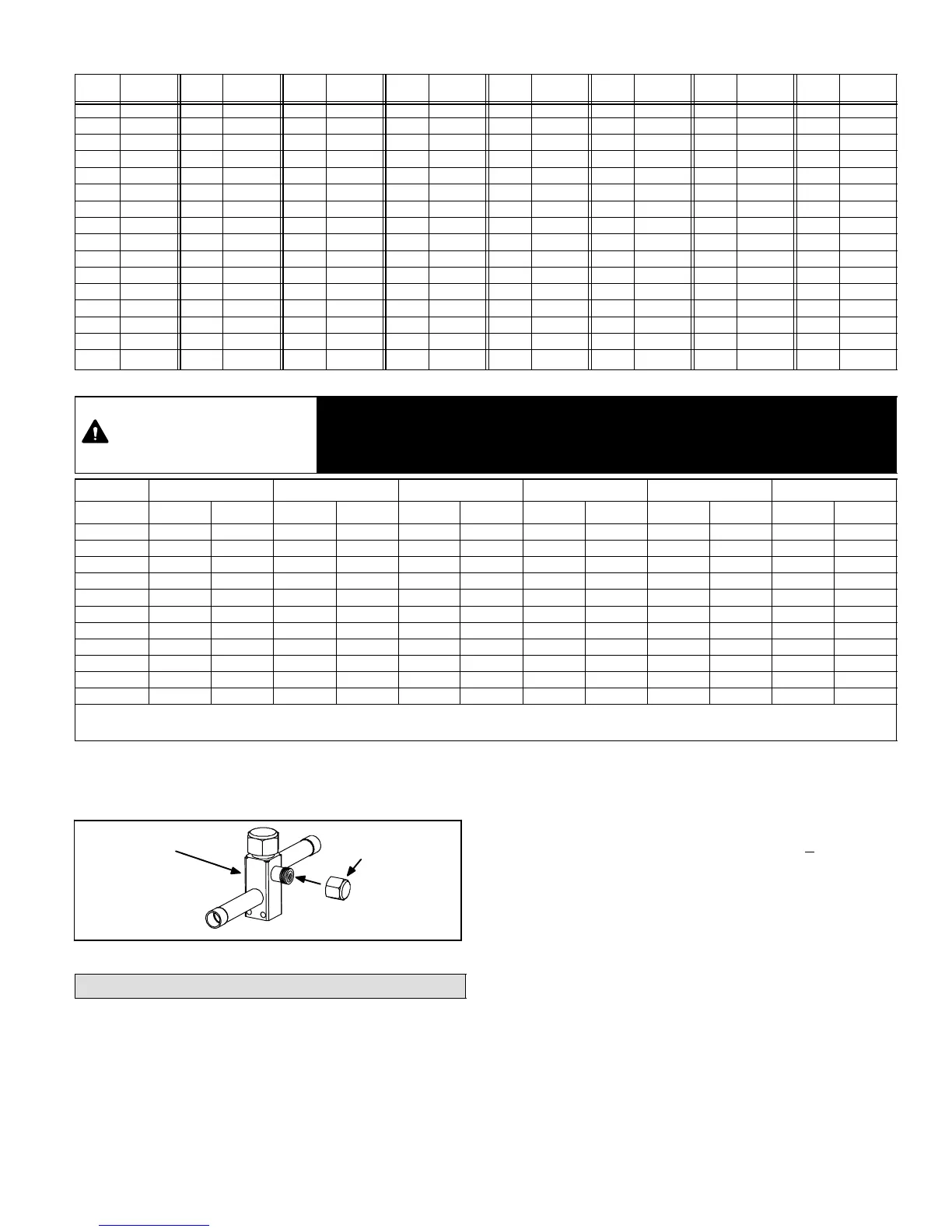

INSTALLING SERVICE VALVE CAPS

Disconnect gauge set and re−install both the liquid and

suction service valve caps.

INSTALL CAPS

OUTDOOR UNIT

SERVICE VALVE

Figure 36. Installing Service Valve Port Caps

System Operation

The outdoor unit and indoor blower cycle on demand from

the room thermostat. When the thermostat blower switch

is in the ON position, the indoor blower operates

continuously.

HIGH PRESSURE SWITCH

XC15 units are equipped with a high-pressure switch that

is located in the liquid line of the compressor as illustrated

in Unit Dimensions on page 2.

The switch is a Single Pole, Single Throw (SPST),

manual−reset switch which is normally closed and

removes power from the compressor when discharge

pressure rises above factory setting at 590 + 10 psi. The

manual−reset switch can be identified by a red cap that is

press to reset the module.

LOW PRESSURE SWITCH

XC15 units are equipped with a low pressure switch that is

located in the suction line to the compressor as illustrated

in Unit Dimensions on page 2. The switch is a Single Pole,

Single Throw (SPST), auto−reset switch that is normal

closed. The switch opens at 40 psi and closes at 90 psi.

FILTER DRIER

A drier is factory−installed in each XC15 unit as illustrated

in Unit Dimensions on page 2. A replacement drier is

available from Lennox. Refer to Lennox Repair Part

Program.

Loading...

Loading...