Page 21

XC15 SERIES

compressor to run. The yellow LED will begin flashing

a code 8 indicating a welded contactor.

3. Disconnect power from the compressor and 24VAC

power from the LSOM. While the LSOM is off, reattach

the wire to the Y terminal.

4. Reapply power to the compressor and 24VAC power

to the LSOM; the yellow LED will flash the previous

code for 60 seconds and then turn off. If the yellow

LED does not function as described, refer to table 7 to

verify the wiring.

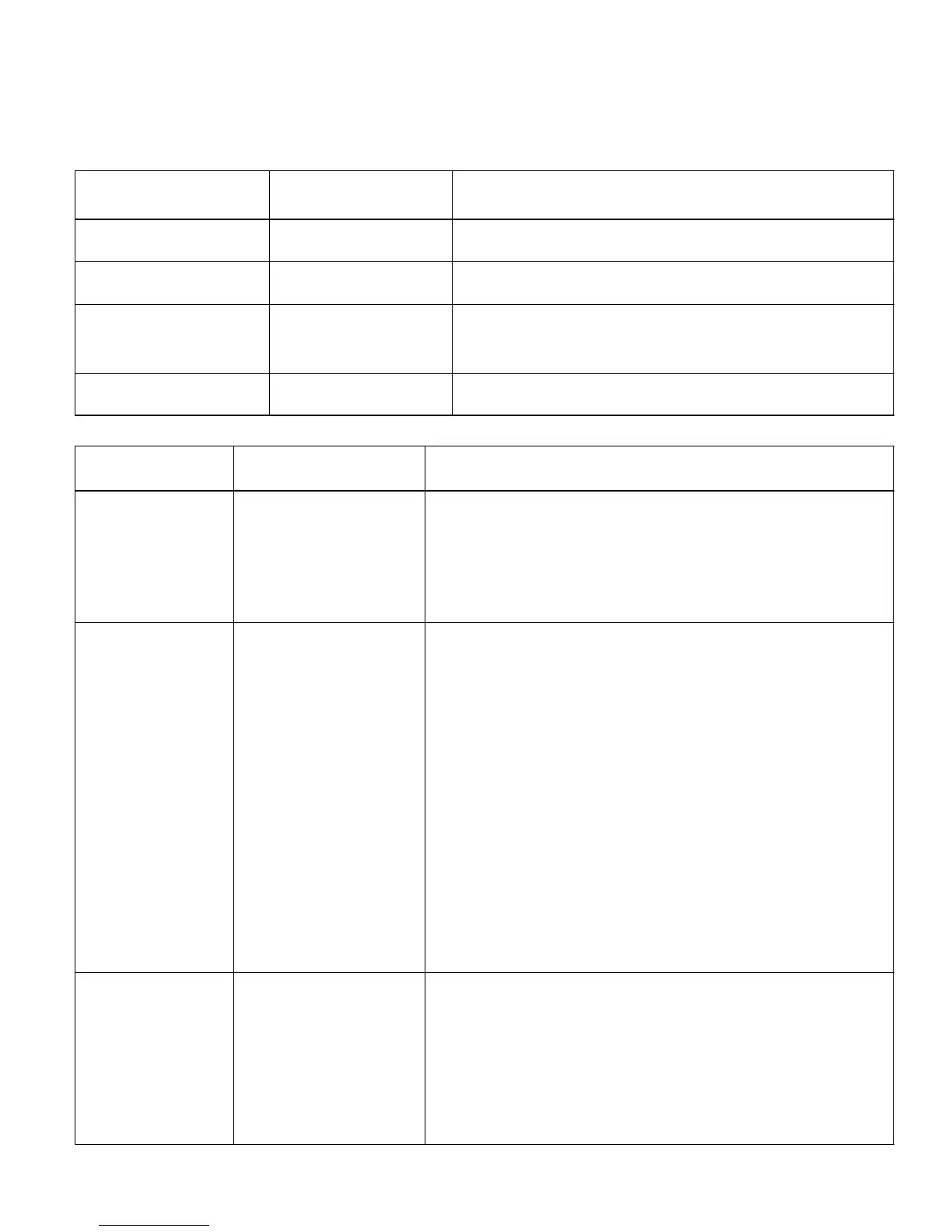

Table 7. LSOM Module LED Troubleshooting Codes

Status LED Condition

Mis−wired Module

Indication

Status LED Troubleshooting Information

Green LED ON Module not powering up.

Determine/verify that both R and C module terminals are connected and

voltage is present at both terminals.

Green LED Intermittent

Module powers up only when

compressor runs.

Determine if R and Y terminals are wired in reverse. Verify module’s R and C

terminals have a constant source.

Red LED ON

LED is on but system and

compressor check OK.

1

Verify Y terminal is connected to 24VAC at contactor coil.

2

Verify voltage at contactor coil falls below 0.5VAC when off.

3

Verify 24VAC is present across Y and C when thermostat demand signal is

present; if not present, R and C wires are reversed.

Red and Yellow LED Simultaneous flashing.

Indicates that the control circuit voltage is too low for operation. Verify R and C

terminals are supplied with 19−28VAC.

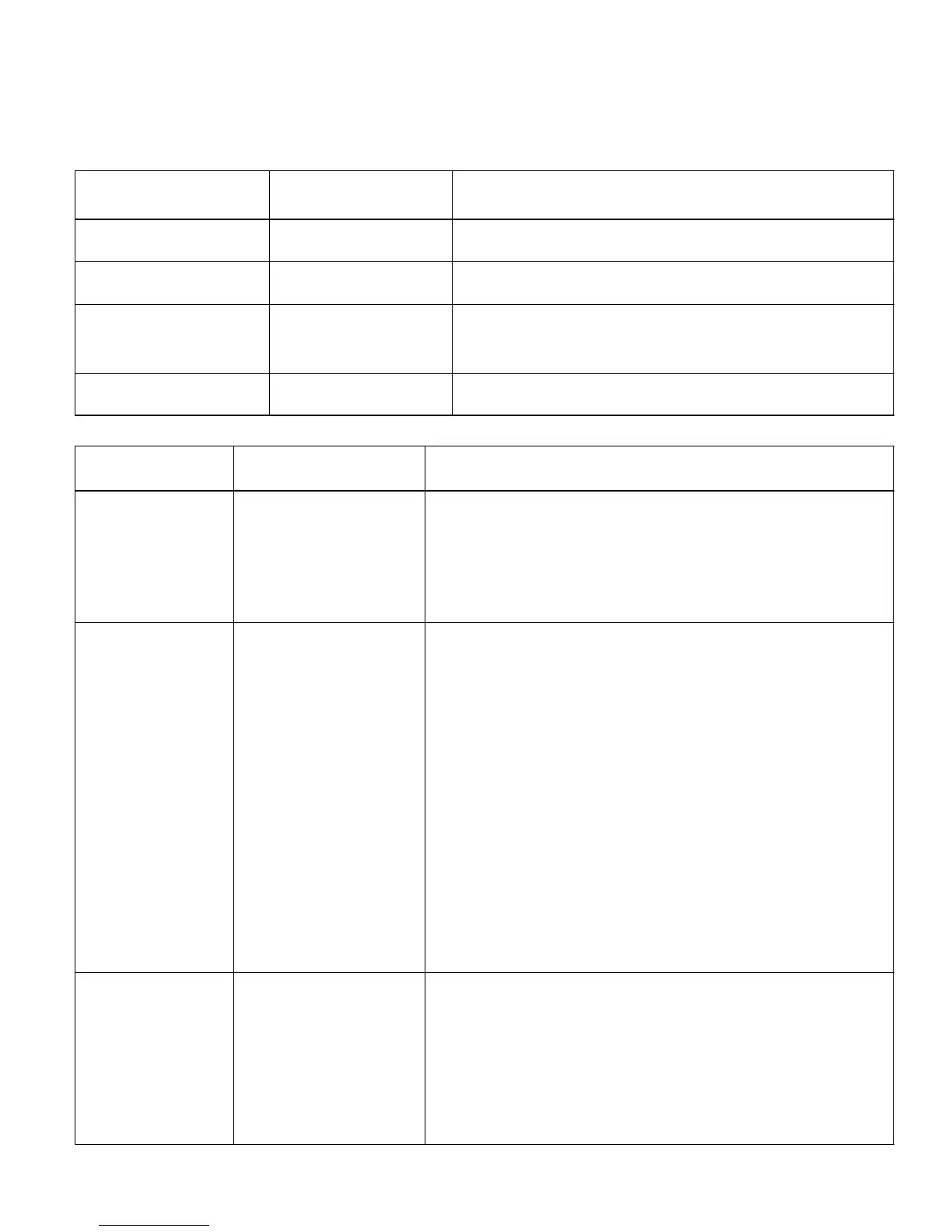

Table 8. LSOM System LED Troubleshooting Codes

Status LED

Condition

Status LED Description Status LED Troubleshooting Information

Red LED ON

Thermostat demand signal Y1 is

present, but compressor not

running

1

Compressor protector is open.

S Check for high head pressure

S Check compressor supply voltage

2

Outdoor unit power disconnect is open.

3

Compressor circuit breaker or fuse(s) is open.

4

Broken wire or connector is not making contact.

5

Low or high pressure switch open if present in the system.

6

Compressor contactor has failed to close.

Yellow Flash Code 1

Long Run Time − Compressor is

running extremely long run

cycles.

1

Low refrigerant charge.

2

Evaporator blower is not running.

S Check blower relay coil and contacts

S Check blower motor capacitor

S Check blower motor for failure or blockage

S Check evaporator blower wiring and connectors

S Check indoor blower control board

S Check thermostat wiring for open circuit

3

Evaporator coil is frozen.

S Check for low suction pressure

S Check for excessively low thermostat setting

S Check evaporator airflow (coil blockages or return air filter)

S Check ductwork or registers for blockage.

4

Faulty metering device.

S Check TXV bulb installation (size, location and contact)

S Check if TXV is stuck closed or defective

5

Condenser coil is dirty

.

6

Liquid line restriction (filter drier blocked if present)

.

7

Thermostat is malfunctioning

.

S Check thermostat sub−base or wiring for short circuit

S Check thermostat installation (location and level)

Yellow Flash Code 2

System Pressure Trip −

Discharge or suction pressure

out of limits or compressor

overloaded

1

High head pressure.

S Check high pressure switch if present in system

S Check if system is overcharged with refrigerant

S Check for non−condensable in system

2

Condenser coil poor air circulation (dirty, blocked, damaged).

3

Condenser fan is not running.

S Check fan capacitor

S Check fan wiring and connectors

S Check fan motor for failure or blockage

4

Return air duct has substantial leakage.

Loading...

Loading...