Page 13

Low gas pulses during compression reduces operational

sound levels.

Compressor motor is internally protected from excessive

current and temperature.

Compressor is installed in the unit on resilient rubber

mounts for vibration free operation.

Compressor B1 operates during all cooling demand and

is energized by contactor K1 upon receiving rst stage de-

mand. Compressor B2 operates only during second stage

cooling demand, and is energized by contactor K2. See

ELECTRICAL section or compressor nameplate for com-

pressor specications.

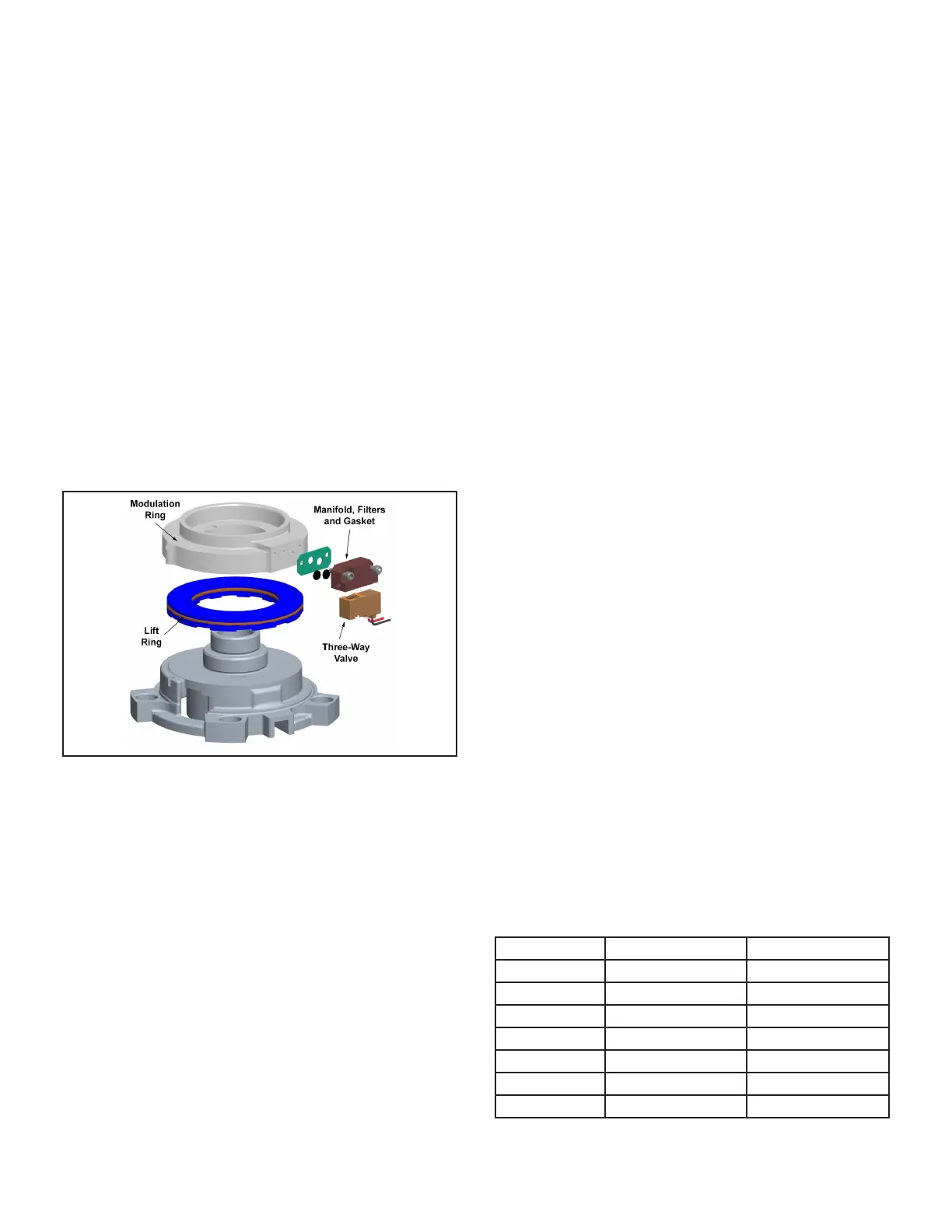

ELS072, ELS090 and ELS120S4S Two Stage Models

A 24-volt DC solenoid valve inside the compressor controls

staging. When the 3-way solenoid is energized it moves

the lift ring assembly to block the ports and the compressor

operates at full-load or 100% capacity. When the solenoid

is de-energized the lift ring assembly moves to unblock the

compressor ports and the compressor operates at part-

load or approximately 67% of its full-load capacity.

The “loading” and “unloading” of the two stage scroll is

done “on the y” without shutting off the single-speed

compressor motor between stages.

FIGURE 2. Two-Stage Scroll Compressor

2 - Crankcase Heaters HR1 (all units) and HR2

(120S4D, 150, 180, 240)

All ELS series units use a belly-band type crankcase heat-

er. Heater HR1 is wrapped around compressor B1 and

heater HR2 is wrapped around compressor B2. HR1 and

HR2 assure proper compressor lubrication at all times.

3 - High Pressure Switch S4 (all units) & S7 (120S4D,

150, 180, 240)

The high pressure switch is a manual-reset SPST N.C.

switch which opens on a pressure rise. The switch is lo-

cated in the compressor discharge line and is wired in se-

ries with the compressor contactor coil. When discharge

pressure rises to 640 + 10 psig (4413 + 69 kP ) the switch

opens and the compressor is de-energized.

4 - Filter Drier (all units)

All ELS model units have a lter drier that is located in the

liquid line of each refrigerant circuit at the exit of each con-

denser coil. The drier removes contaminants and moisture

from the system.

5 - Condenser Fan B4 (all units) B5 (120S4S,120S4D,

150, 180, 240) B21 & B22 (180, 240)

See pages 2 and 3 for the specications on the condens-

er fans used in the ELS units. All condenser fans have

single- phase motors. The ELS072 and 090 units are

equipped with a single condenser fan. The ELS120 and

150 are equipped with two fans and the 180 and 240 have

four fans. The fan assembly may be removed for servicing

by removing the fan grill, unplugging the motor then loos-

ening the motor bracket. The assembly will lift out.

6 - Loss of Charge Switch S24 & S25

The loss of charge switch is an auto-reset SPST N.C.

switch which opens on a pressure drop (almost a complete

loss of charge). All ELS units have S24 and the 120S4D

through 240 have S25. The switch is located in the liquid

line and wired in series with compressor contactor and

high pressure switch. S24 is wired in series with rst stage

cool and S25 is wired in series with second stage cool.

When pressure drops below 40+ 5 psig (indicating loss of

charge in the system) the switch opens and compressor

is de-energized. The switch automatically resets when re-

frigerant is added and pressure in the discharge line rises

above 90+ 5 psig.

7 - Head Pressure Control A190 & A191 and Pressure

Transducer A188 & A189

The low ambient kit is designed to maintain the head pres-

sure across the liquid line by varying the condenser speed

fan.

Head pressure Control A190 (all units) and A191 (ELS180,

240) is used to set the desired liquid line pressure (315

psig in ELS units). The pressure transducer A190 (All

units) A191 (120S4D through 240) measures the liquid

line pressure sending an analog signal to the head pres-

sure controller. If pressure falls below set point, the head

pressure controller reduces the fan speed to increase the

liquid line pressure to the set point.

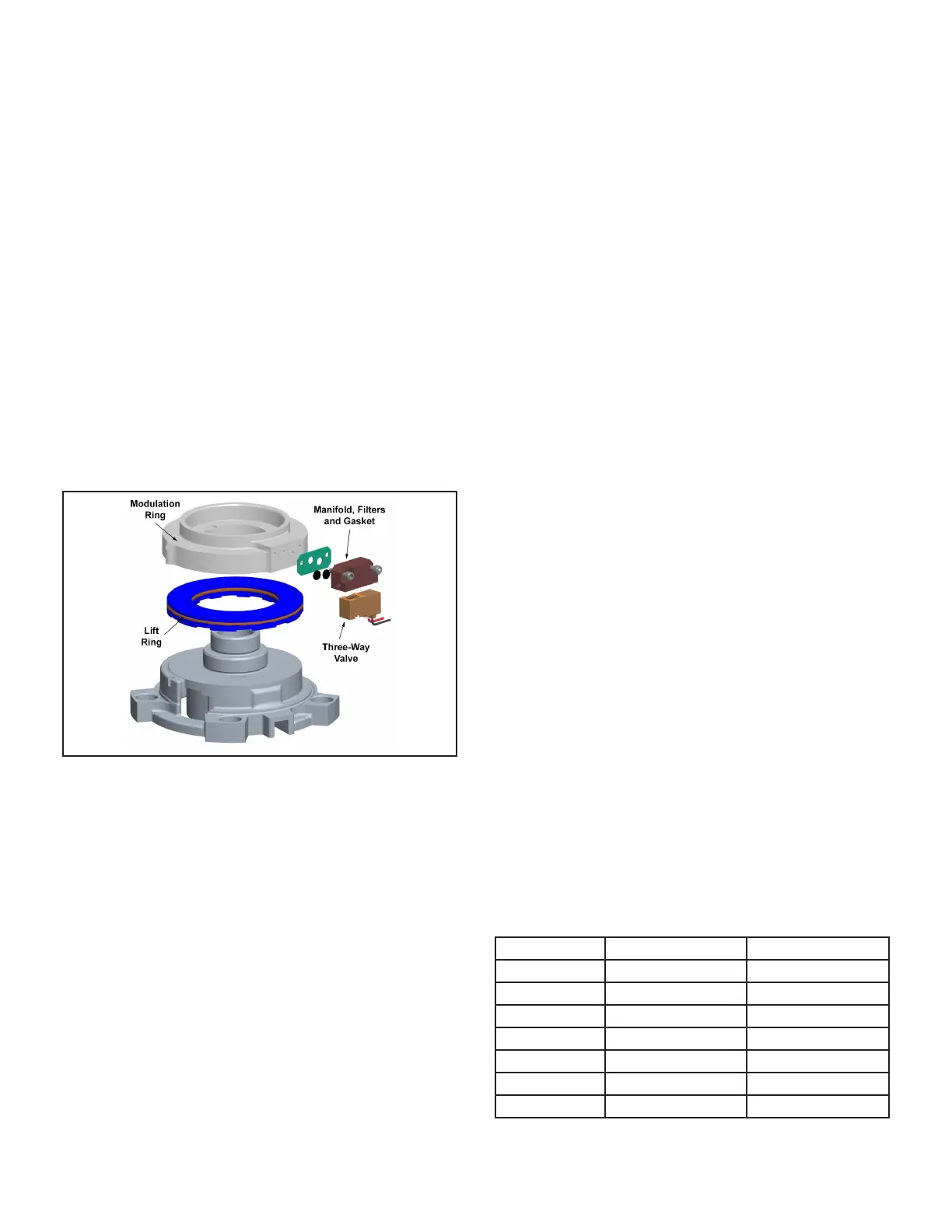

II- REFRIGERANT SYSTEM

A-Plumbing

Field refrigerant piping consists of liquid and suction lines

connecting the condensing unit and the indoor unit. Liquid

and suction service valves are located in a compartment

at the corner of the unit below the control box. Piping can

be routed directly from the service valves or eld supplied

elbows can be added to divert the piping as required Refer

to table 1 for eld-fabricated refrigerant line sizes for runs

up to 50 linear feet (15 m).

TABLE 1

ELS Unit Liquid Line Suction Line

072 3/8" (10mm) 1-1/8" (29mm)

090 5/8" (16mm) 1-1/8" (29mm)

120S4S 5/8" (16mm) 1-1/8" (29mm)

120S4D 3/8" (10mm) 1-1/8" (29mm)

150 3/8" (10mm) 1-1/8" (29mm)

180 5/8" (16mm) 1-1/8" (29mm)

240 5/8" (16mm) 1-1/8" (29mm)

Loading...

Loading...