Page 15

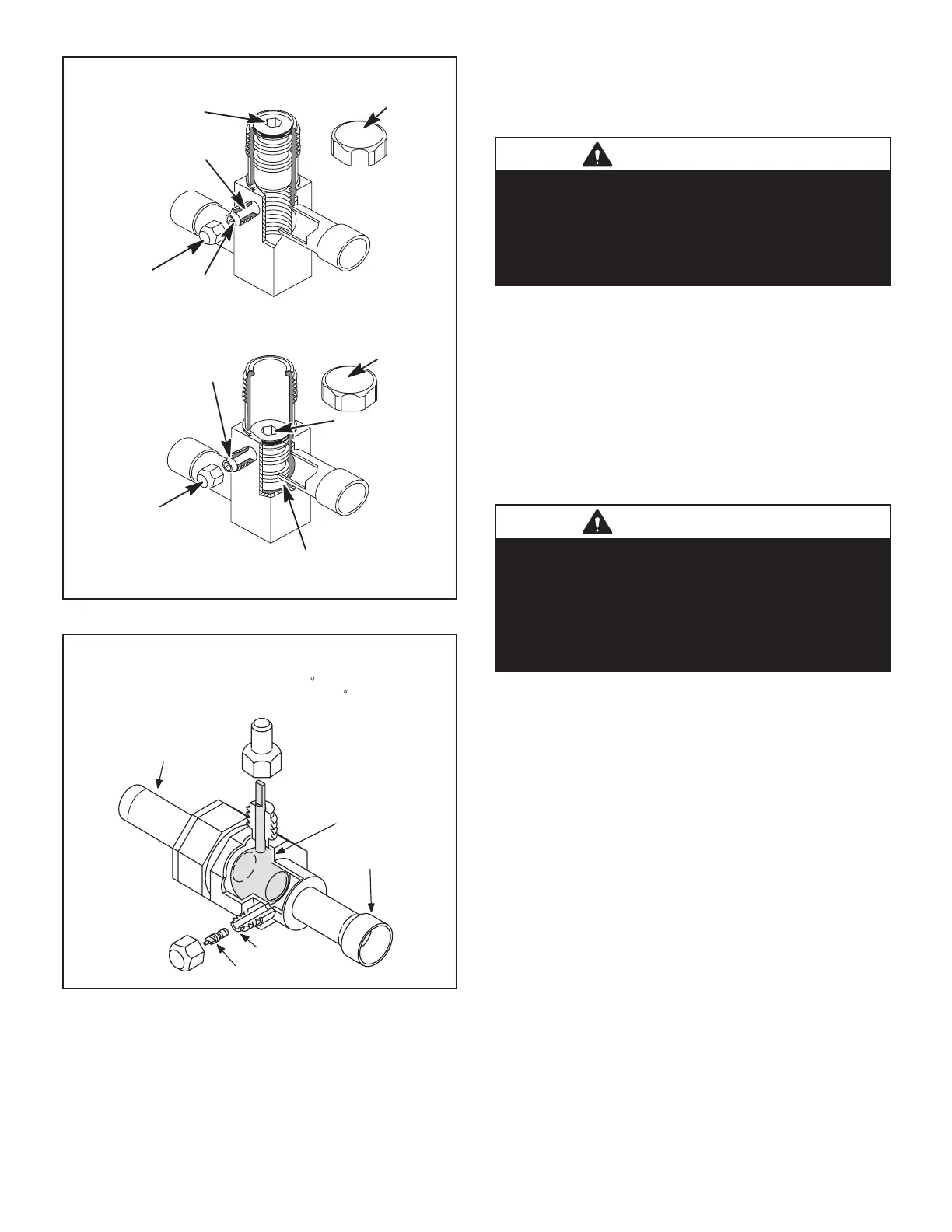

Liquid And Suction Line Service Valve

(Valve Open)

Schrader

valve

service

port

service port

cap

insert hex

wrench here

to indoor coil

to outdoor coil

stem cap

Schrader valve open

to line set when valve

is closed (front seated)

service

port

service

port cap

stem cap

insert hex

wrench here

Liquid And Suction Line Service Valve

(Valve Closed)

(valve front seated)

to outdoor coil

to indoor coil

FIGURE 4

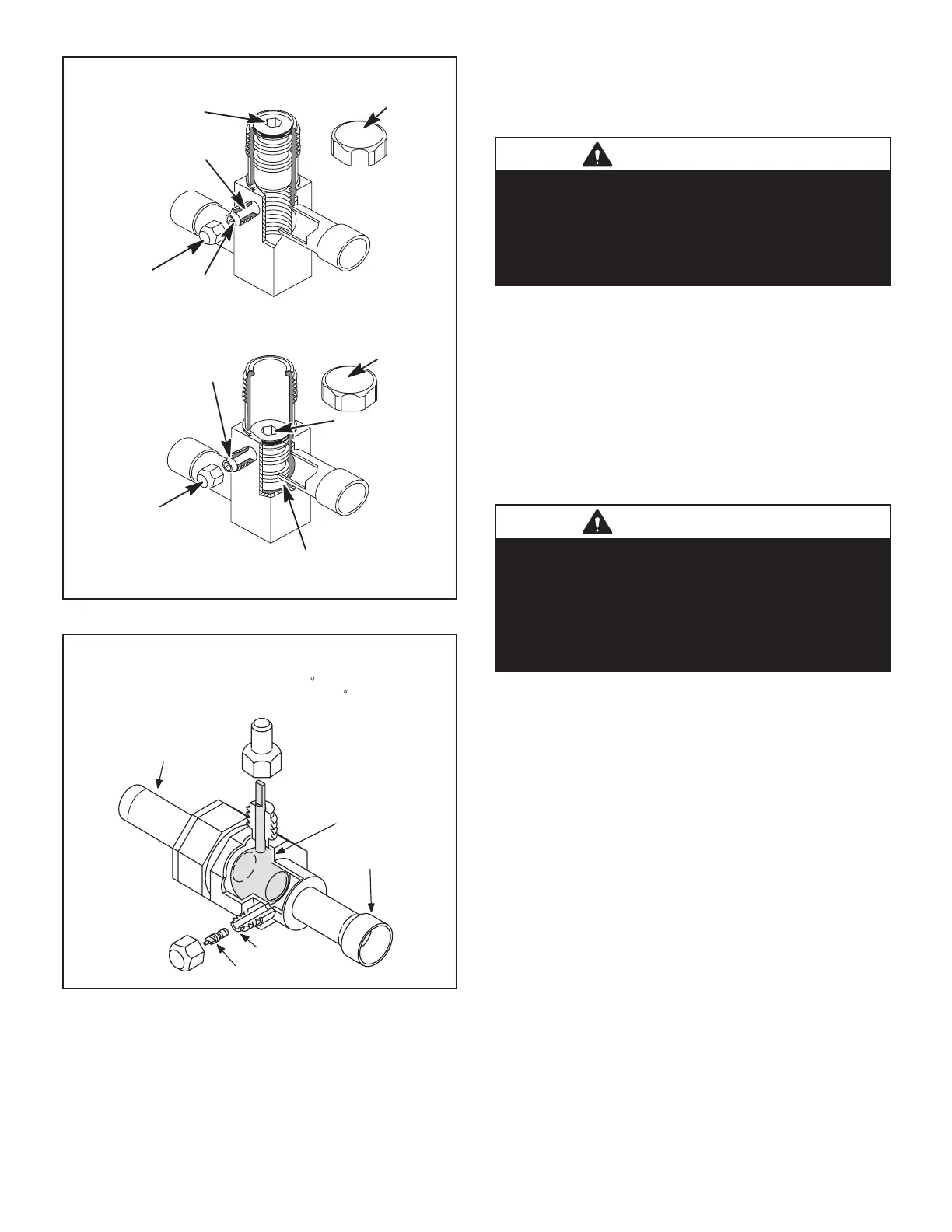

SUCTION LINE (BALL TYPE) SERVICE VALVE

VALVE CORE

SERVICE PORT

STEM CAP

STEM

USE ADJUSTABLE WRENCH

ROTATE STEM CLOCKWISE 90

TO CLOSE

ROTATE STEM COUNTERCLOCKWISE 90

TO OPEN

BALL

(SHOWN OPEN)

FROM INDOOR COIL

TO COMPRESSOR

SERVICE PORT

CAP

FIGURE 5

III-START-UP

The following is a general procedure and does not apply

to all thermostat control systems. Refer to sequence of

operation in this manual for more information.

IMPORTANT

Crankcase heaters must be energized for 24 hours before

attempting to start compressors. Set thermostat so there

is no compressor demand before closing disconnect

switch. Attempting to start compressors during the 24-

hour warm-up period could result in damage or failed

compressors.

1 - Set fan switch to AUTO or ON and move the system

selection switch to COOL. Adjust the thermostat to a

setting far enough below room temperature to bring

on compressors. Compressors will start and cycle

on demand from the thermostat (allowing for unit

and thermostat time delays).

2 - Each circuit is eld charged with HCFC-410A

refrigerant.

3 - Refer to Charging section for proper method of

checking and charging the system.

IMPORTANT

Three-phase scroll compressors must be phased

sequentially to ensure correct compressor rotation

and operation. At compressor start-up, a rise in

discharge and drop in suction pressures indicate proper

compressor phasing and operation. If discharge and

suctions pressures do not perform normally, follow the

steps below to correctly phase in the unit.

1 - Disconnect power to the unit.

2 - Reverse any two eld power leads (L1 and L3

preferred) to the unit.

3 - Reapply power to the unit.

Discharge and suction pressures should operate at their

normal start-up ranges.

NOTE - Compressor noise level will be signicantly high-

er when phasing is incorrect and the unit will not provide

cooling when compressor is operating backwards. Con-

tinued backward operation will cause the compressor to

cycle on internal protector.

Loading...

Loading...